| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147881 | Chemical Engineering Journal | 2014 | 6 Pages |

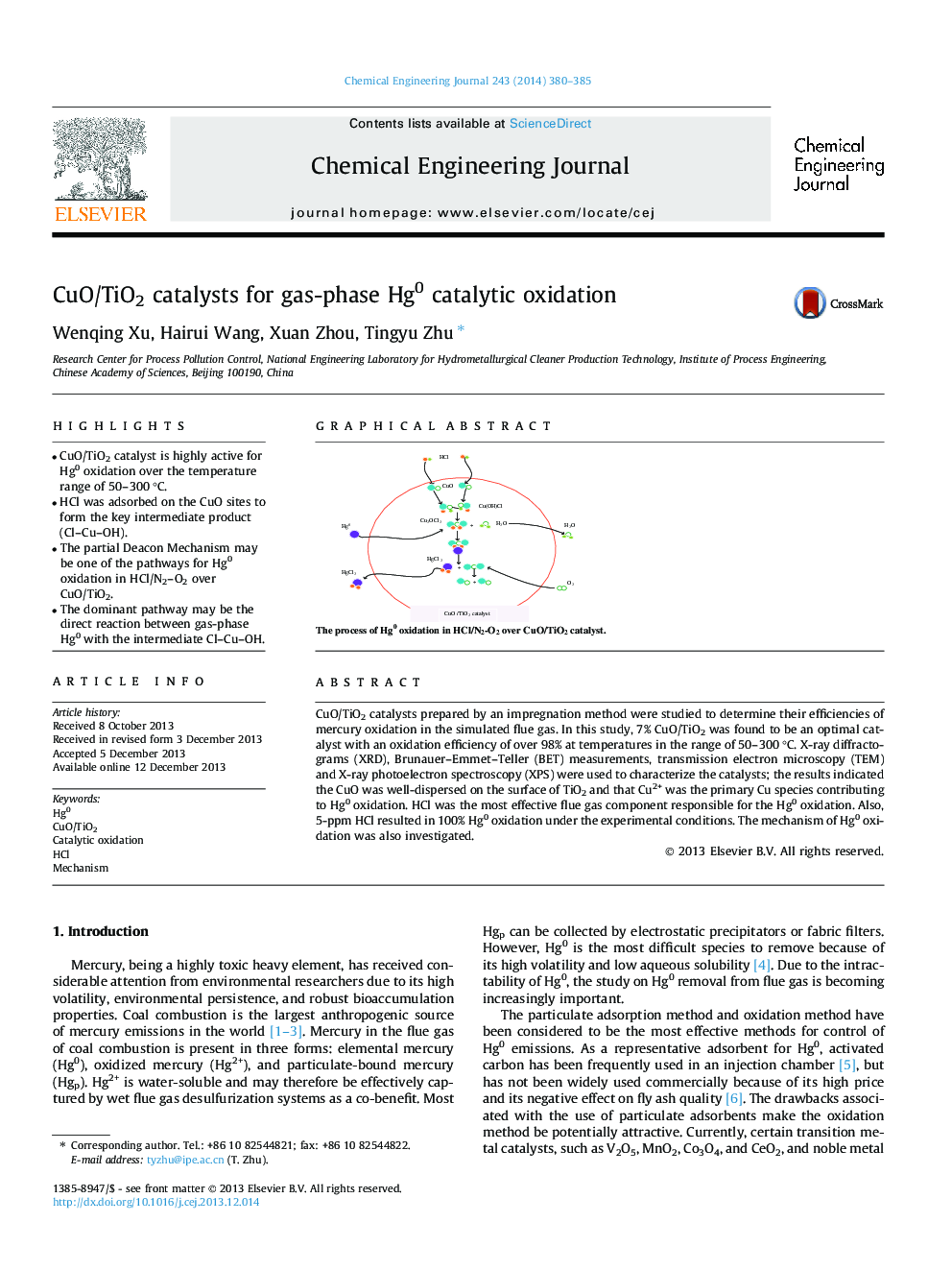

•CuO/TiO2 catalyst is highly active for Hg0 oxidation over the temperature range of 50–300 °C.•HCl was adsorbed on the CuO sites to form the key intermediate product (Cl–Cu–OH).•The partial Deacon Mechanism may be one of the pathways for Hg0 oxidation in HCl/N2–O2 over CuO/TiO2.•The dominant pathway may be the direct reaction between gas-phase Hg0 with the intermediate Cl–Cu–OH.

CuO/TiO2 catalysts prepared by an impregnation method were studied to determine their efficiencies of mercury oxidation in the simulated flue gas. In this study, 7% CuO/TiO2 was found to be an optimal catalyst with an oxidation efficiency of over 98% at temperatures in the range of 50–300 °C. X-ray diffractograms (XRD), Brunauer–Emmet–Teller (BET) measurements, transmission electron microscopy (TEM) and X-ray photoelectron spectroscopy (XPS) were used to characterize the catalysts; the results indicated the CuO was well-dispersed on the surface of TiO2 and that Cu2+ was the primary Cu species contributing to Hg0 oxidation. HCl was the most effective flue gas component responsible for the Hg0 oxidation. Also, 5-ppm HCl resulted in 100% Hg0 oxidation under the experimental conditions. The mechanism of Hg0 oxidation was also investigated.

Graphical abstractThe process of Hg0 oxidation in HCl/N2–O2 over CuO/TiO2 catalyst.Figure optionsDownload full-size imageDownload as PowerPoint slide