| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147911 | Chemical Engineering Journal | 2014 | 12 Pages |

•The selective acetylation of glycerol with acetic acid was investigated.•TAG was produced with very high selectivity of 55% with minimal MAG formed.•3%Y/SBA-3 catalyst was the best catalyst to achieve glycerol conversion of 100%.•The best reaction conditions are; T = 110 °C, time = 2.5 h, catalyst loading = 0.05 g.

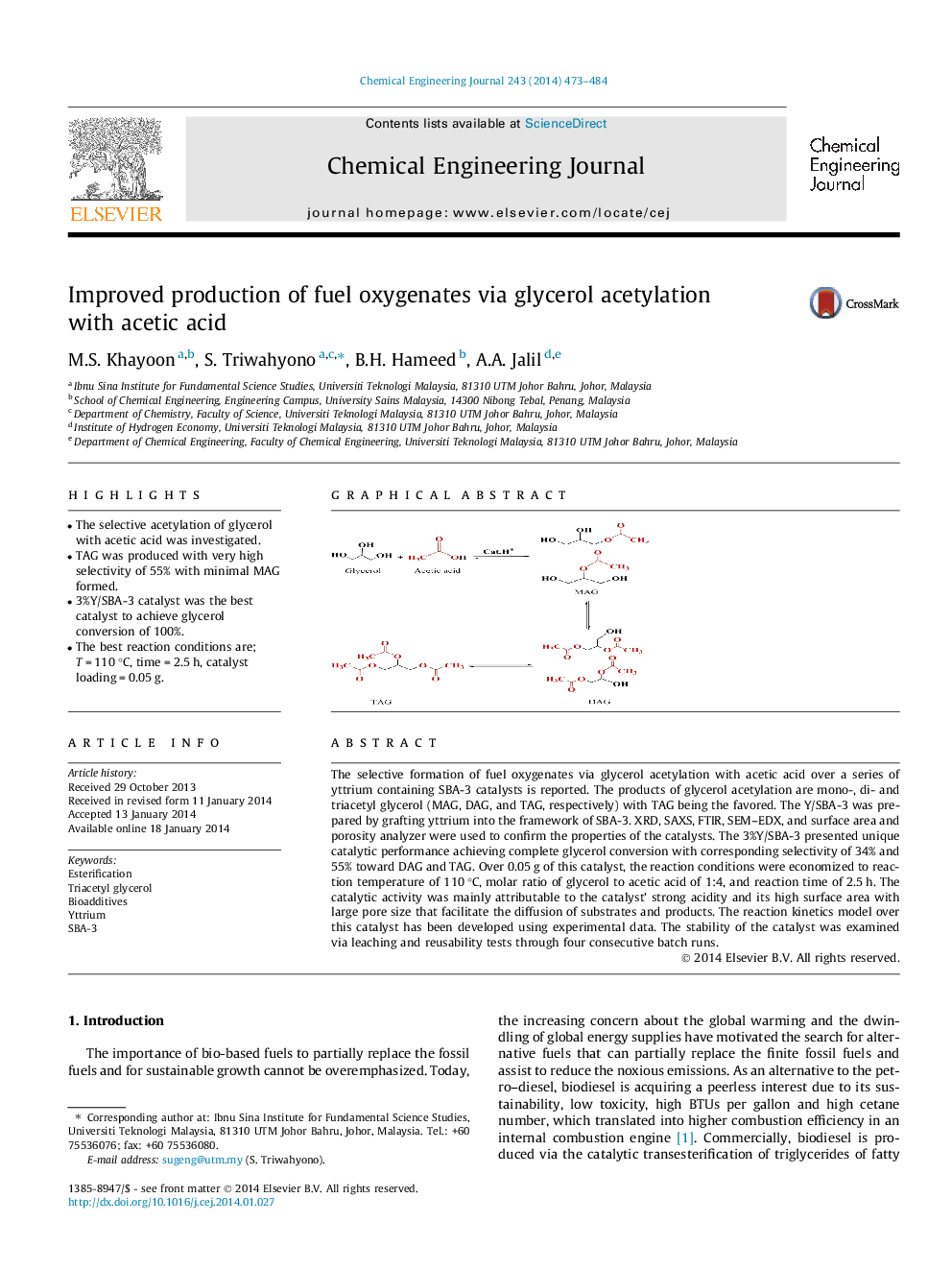

The selective formation of fuel oxygenates via glycerol acetylation with acetic acid over a series of yttrium containing SBA-3 catalysts is reported. The products of glycerol acetylation are mono-, di- and triacetyl glycerol (MAG, DAG, and TAG, respectively) with TAG being the favored. The Y/SBA-3 was prepared by grafting yttrium into the framework of SBA-3. XRD, SAXS, FTIR, SEM–EDX, and surface area and porosity analyzer were used to confirm the properties of the catalysts. The 3%Y/SBA-3 presented unique catalytic performance achieving complete glycerol conversion with corresponding selectivity of 34% and 55% toward DAG and TAG. Over 0.05 g of this catalyst, the reaction conditions were economized to reaction temperature of 110 °C, molar ratio of glycerol to acetic acid of 1:4, and reaction time of 2.5 h. The catalytic activity was mainly attributable to the catalyst’ strong acidity and its high surface area with large pore size that facilitate the diffusion of substrates and products. The reaction kinetics model over this catalyst has been developed using experimental data. The stability of the catalyst was examined via leaching and reusability tests through four consecutive batch runs.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide