| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147988 | Chemical Engineering Journal | 2014 | 8 Pages |

•H2–CCl4 mixture plasma treatment was used to improve TiO2 photocatalytic activity.•The doping C and surface Cl contents increased obviously by using this plasma treated method.•Cl is effective in oxidizing aromatic side groups, but ineffective in reactions with the aromatic ring.•The photocatalytic stability was improved by using this plasma treated method.

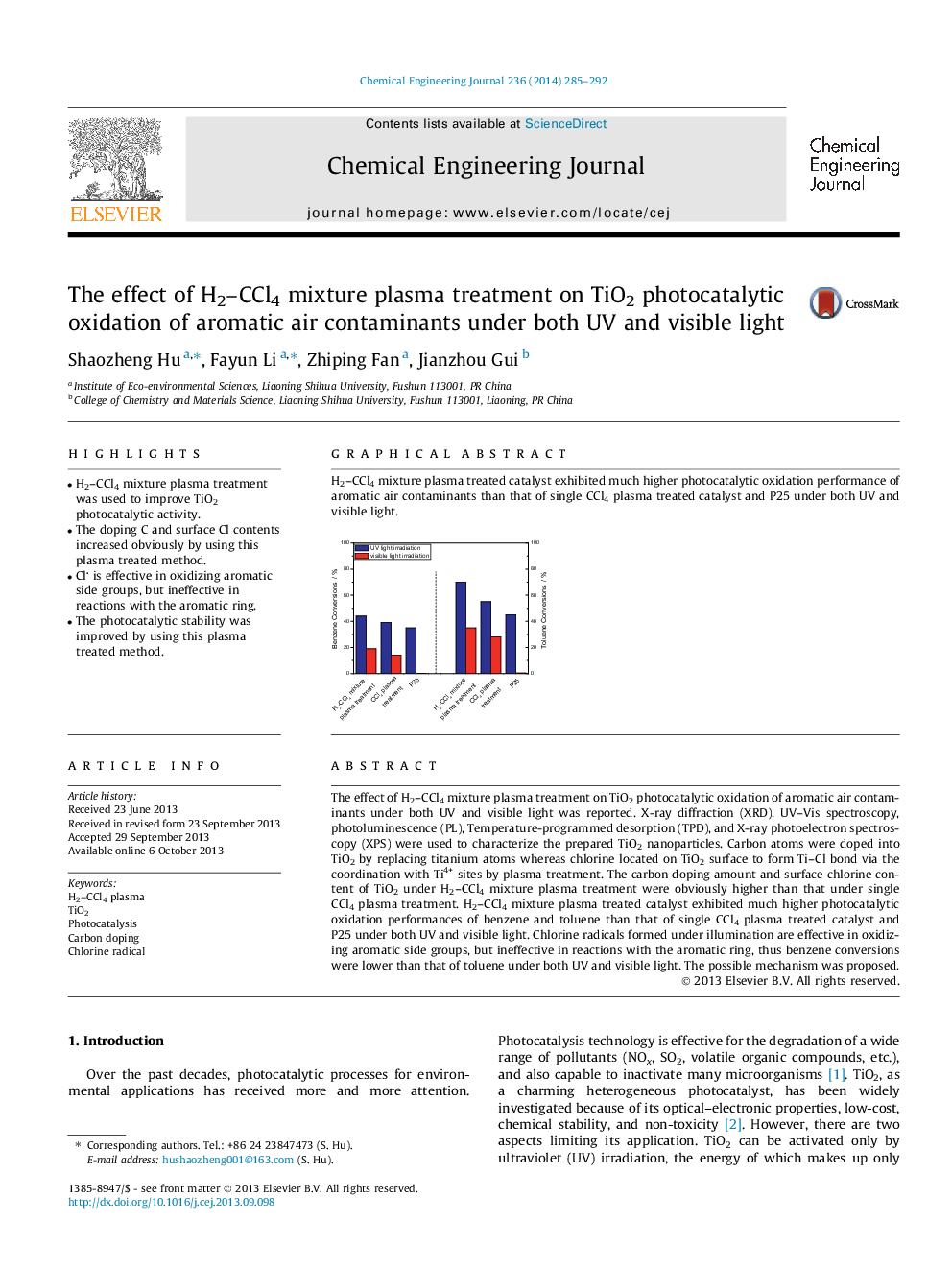

The effect of H2–CCl4 mixture plasma treatment on TiO2 photocatalytic oxidation of aromatic air contaminants under both UV and visible light was reported. X-ray diffraction (XRD), UV–Vis spectroscopy, photoluminescence (PL), Temperature-programmed desorption (TPD), and X-ray photoelectron spectroscopy (XPS) were used to characterize the prepared TiO2 nanoparticles. Carbon atoms were doped into TiO2 by replacing titanium atoms whereas chlorine located on TiO2 surface to form Ti–Cl bond via the coordination with Ti4+ sites by plasma treatment. The carbon doping amount and surface chlorine content of TiO2 under H2–CCl4 mixture plasma treatment were obviously higher than that under single CCl4 plasma treatment. H2–CCl4 mixture plasma treated catalyst exhibited much higher photocatalytic oxidation performances of benzene and toluene than that of single CCl4 plasma treated catalyst and P25 under both UV and visible light. Chlorine radicals formed under illumination are effective in oxidizing aromatic side groups, but ineffective in reactions with the aromatic ring, thus benzene conversions were lower than that of toluene under both UV and visible light. The possible mechanism was proposed.

Graphical abstractH2–CCl4 mixture plasma treated catalyst exhibited much higher photocatalytic oxidation performance of aromatic air contaminants than that of single CCl4 plasma treated catalyst and P25 under both UV and visible light.Figure optionsDownload full-size imageDownload as PowerPoint slide