| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 148338 | Chemical Engineering Journal | 2014 | 9 Pages |

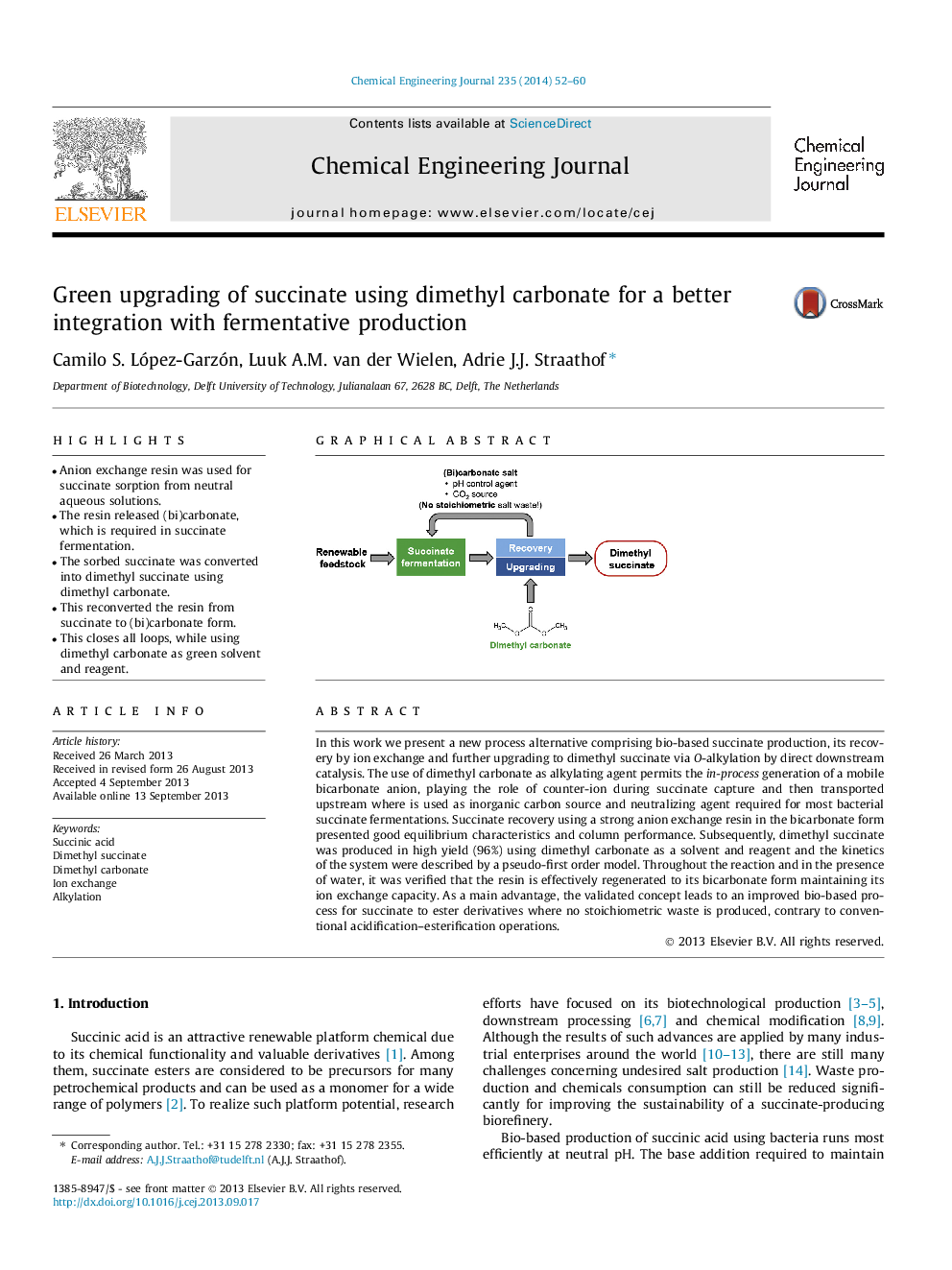

•Anion exchange resin was used for succinate sorption from neutral aqueous solutions.•The resin released (bi)carbonate, which is required in succinate fermentation.•The sorbed succinate was converted into dimethyl succinate using dimethyl carbonate.•This reconverted the resin from succinate to (bi)carbonate form.•This closes all loops, while using dimethyl carbonate as green solvent and reagent.

In this work we present a new process alternative comprising bio-based succinate production, its recovery by ion exchange and further upgrading to dimethyl succinate via O-alkylation by direct downstream catalysis. The use of dimethyl carbonate as alkylating agent permits the in-process generation of a mobile bicarbonate anion, playing the role of counter-ion during succinate capture and then transported upstream where is used as inorganic carbon source and neutralizing agent required for most bacterial succinate fermentations. Succinate recovery using a strong anion exchange resin in the bicarbonate form presented good equilibrium characteristics and column performance. Subsequently, dimethyl succinate was produced in high yield (96%) using dimethyl carbonate as a solvent and reagent and the kinetics of the system were described by a pseudo-first order model. Throughout the reaction and in the presence of water, it was verified that the resin is effectively regenerated to its bicarbonate form maintaining its ion exchange capacity. As a main advantage, the validated concept leads to an improved bio-based process for succinate to ester derivatives where no stoichiometric waste is produced, contrary to conventional acidification–esterification operations.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide