| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 148777 | Chemical Engineering Journal | 2013 | 6 Pages |

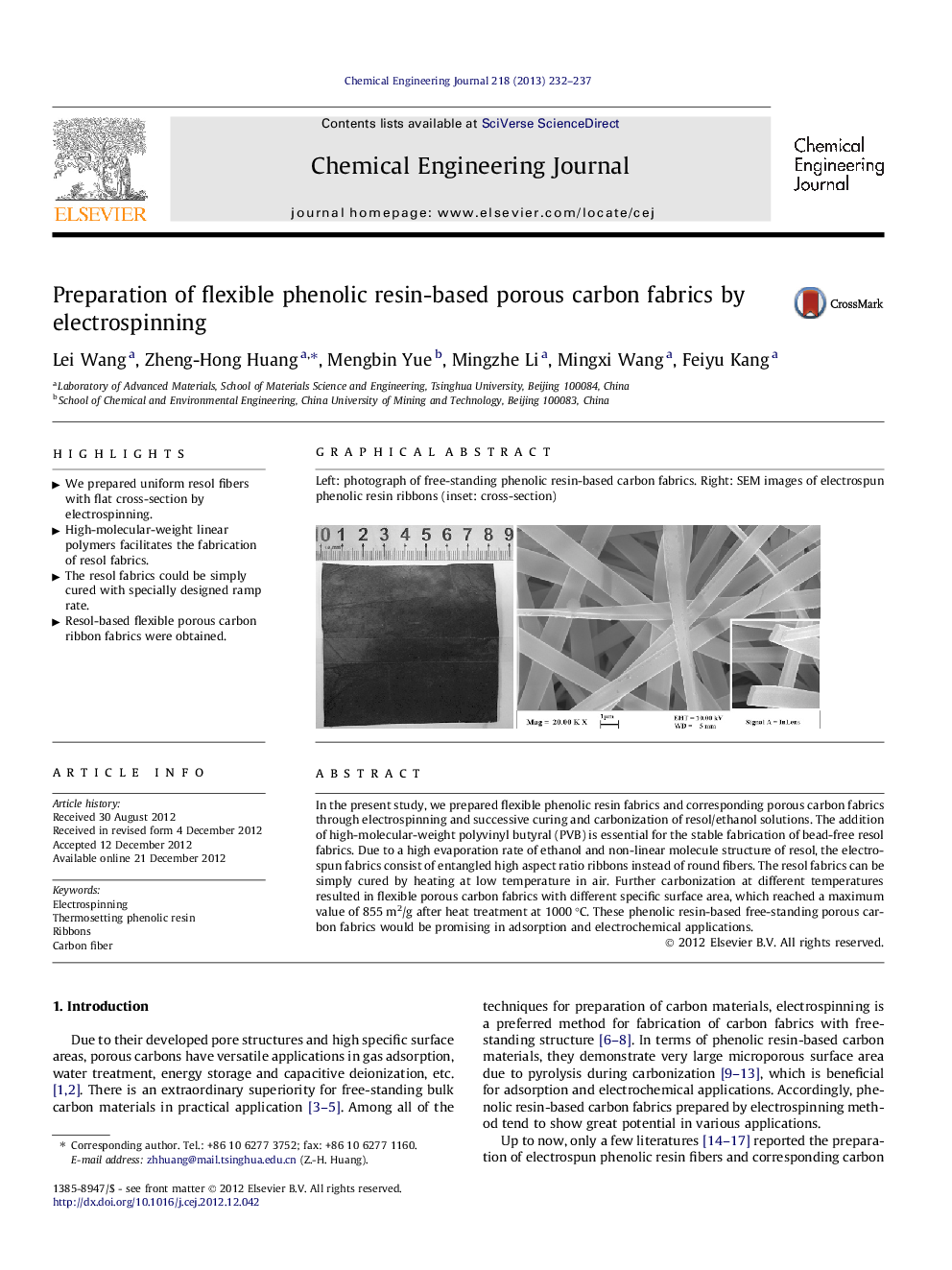

In the present study, we prepared flexible phenolic resin fabrics and corresponding porous carbon fabrics through electrospinning and successive curing and carbonization of resol/ethanol solutions. The addition of high-molecular-weight polyvinyl butyral (PVB) is essential for the stable fabrication of bead-free resol fabrics. Due to a high evaporation rate of ethanol and non-linear molecule structure of resol, the electrospun fabrics consist of entangled high aspect ratio ribbons instead of round fibers. The resol fabrics can be simply cured by heating at low temperature in air. Further carbonization at different temperatures resulted in flexible porous carbon fabrics with different specific surface area, which reached a maximum value of 855 m2/g after heat treatment at 1000 °C. These phenolic resin-based free-standing porous carbon fabrics would be promising in adsorption and electrochemical applications.

Graphical abstractLeft: photograph of free-standing phenolic resin-based carbon fabrics. Right: SEM images of electrospun phenolic resin ribbons (inset: cross-section)Figure optionsDownload full-size imageDownload as PowerPoint slideHighlights• We prepared uniform resol fibers with flat cross-section by electrospinning. • High-molecular-weight linear polymers facilitates the fabrication of resol fabrics. • The resol fabrics could be simply cured with specially designed ramp rate. • Resol-based flexible porous carbon ribbon fabrics were obtained.