| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 148787 | Chemical Engineering Journal | 2013 | 9 Pages |

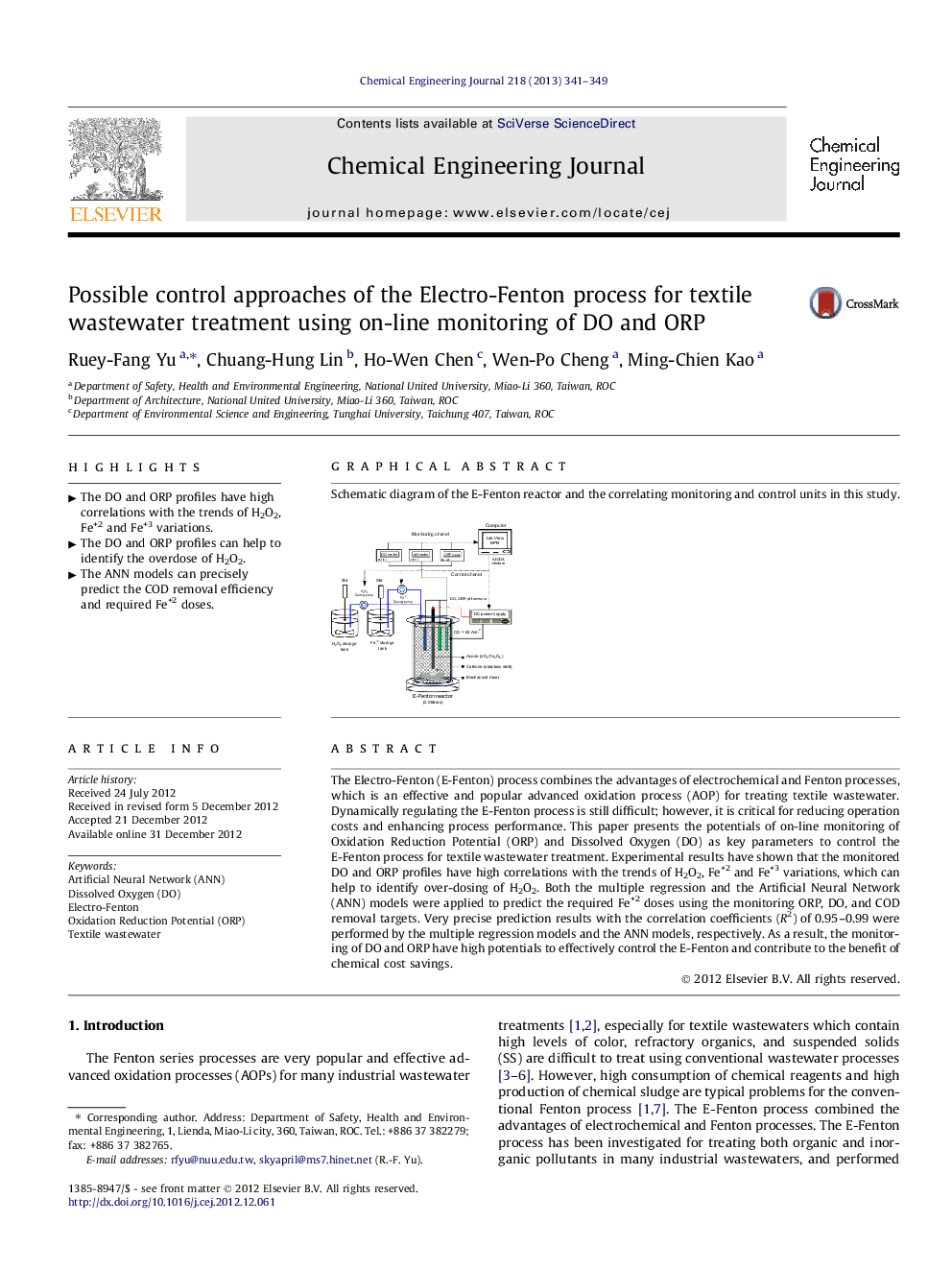

The Electro-Fenton (E-Fenton) process combines the advantages of electrochemical and Fenton processes, which is an effective and popular advanced oxidation process (AOP) for treating textile wastewater. Dynamically regulating the E-Fenton process is still difficult; however, it is critical for reducing operation costs and enhancing process performance. This paper presents the potentials of on-line monitoring of Oxidation Reduction Potential (ORP) and Dissolved Oxygen (DO) as key parameters to control the E-Fenton process for textile wastewater treatment. Experimental results have shown that the monitored DO and ORP profiles have high correlations with the trends of H2O2, Fe+2 and Fe+3 variations, which can help to identify over-dosing of H2O2. Both the multiple regression and the Artificial Neural Network (ANN) models were applied to predict the required Fe+2 doses using the monitoring ORP, DO, and COD removal targets. Very precise prediction results with the correlation coefficients (R2) of 0.95–0.99 were performed by the multiple regression models and the ANN models, respectively. As a result, the monitoring of DO and ORP have high potentials to effectively control the E-Fenton and contribute to the benefit of chemical cost savings.

Graphical abstractSchematic diagram of the E-Fenton reactor and the correlating monitoring and control units in this study.Figure optionsDownload full-size imageDownload as PowerPoint slideHighlights• The DO and ORP profiles have high correlations with the trends of H2O2, Fe+2 and Fe+3 variations. • The DO and ORP profiles can help to identify the overdose of H2O2. • The ANN models can precisely predict the COD removal efficiency and required Fe+2 doses.