| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 149468 | Chemical Engineering Journal | 2012 | 10 Pages |

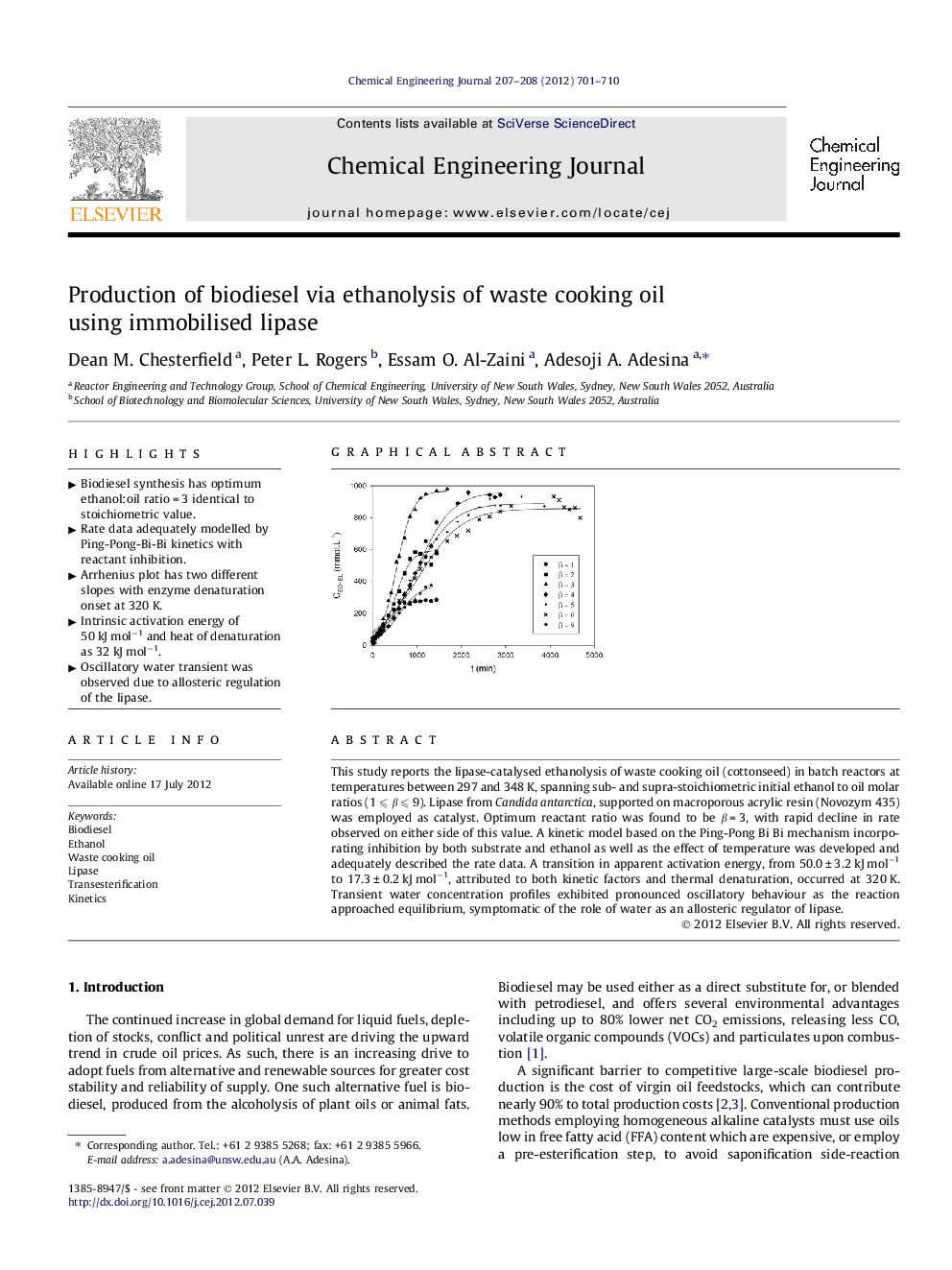

This study reports the lipase-catalysed ethanolysis of waste cooking oil (cottonseed) in batch reactors at temperatures between 297 and 348 K, spanning sub- and supra-stoichiometric initial ethanol to oil molar ratios (1 ⩽ β ⩽ 9). Lipase from Candida antarctica, supported on macroporous acrylic resin (Novozym 435) was employed as catalyst. Optimum reactant ratio was found to be β = 3, with rapid decline in rate observed on either side of this value. A kinetic model based on the Ping-Pong Bi Bi mechanism incorporating inhibition by both substrate and ethanol as well as the effect of temperature was developed and adequately described the rate data. A transition in apparent activation energy, from 50.0 ± 3.2 kJ mol−1 to 17.3 ± 0.2 kJ mol−1, attributed to both kinetic factors and thermal denaturation, occurred at 320 K. Transient water concentration profiles exhibited pronounced oscillatory behaviour as the reaction approached equilibrium, symptomatic of the role of water as an allosteric regulator of lipase.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slideHighlights• Biodiesel synthesis has optimum ethanol:oil ratio = 3 identical to stoichiometric value. • Rate data adequately modelled by Ping-Pong-Bi-Bi kinetics with reactant inhibition. • Arrhenius plot has two different slopes with enzyme denaturation onset at 320 K. • Intrinsic activation energy of 50 kJ mol−1 and heat of denaturation as 32 kJ mol−1. • Oscillatory water transient was observed due to allosteric regulation of the lipase.