| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465029 | Chemical Engineering Journal | 2017 | 8 Pages |

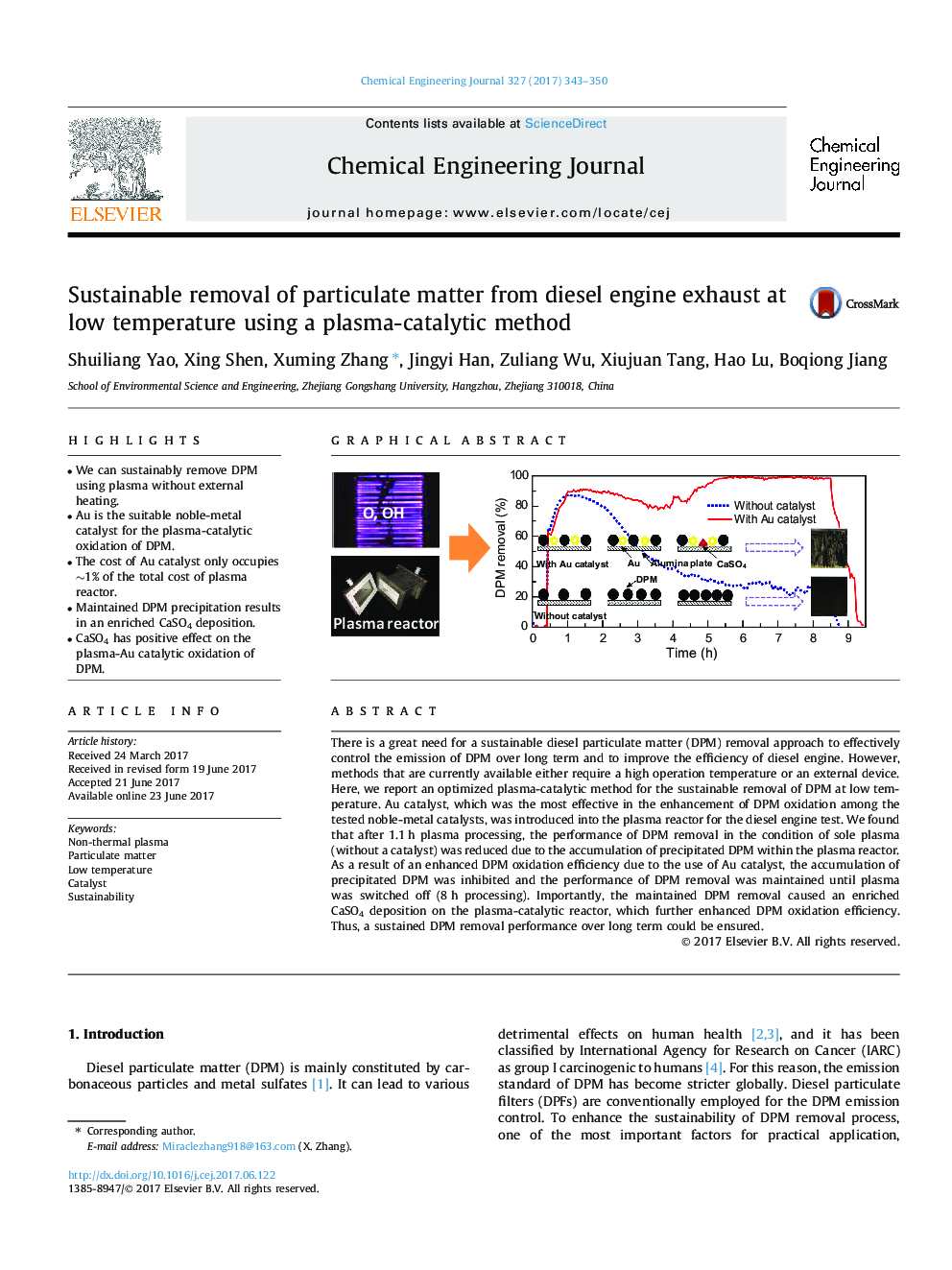

â¢We can sustainably remove DPM using plasma without external heating.â¢Au is the suitable noble-metal catalyst for the plasma-catalytic oxidation of DPM.â¢The cost of Au catalyst only occupies â¼1% of the total cost of plasma reactor.â¢Maintained DPM precipitation results in an enriched CaSO4 deposition.â¢CaSO4 has positive effect on the plasma-Au catalytic oxidation of DPM.

There is a great need for a sustainable diesel particulate matter (DPM) removal approach to effectively control the emission of DPM over long term and to improve the efficiency of diesel engine. However, methods that are currently available either require a high operation temperature or an external device. Here, we report an optimized plasma-catalytic method for the sustainable removal of DPM at low temperature. Au catalyst, which was the most effective in the enhancement of DPM oxidation among the tested noble-metal catalysts, was introduced into the plasma reactor for the diesel engine test. We found that after 1.1Â h plasma processing, the performance of DPM removal in the condition of sole plasma (without a catalyst) was reduced due to the accumulation of precipitated DPM within the plasma reactor. As a result of an enhanced DPM oxidation efficiency due to the use of Au catalyst, the accumulation of precipitated DPM was inhibited and the performance of DPM removal was maintained until plasma was switched off (8Â h processing). Importantly, the maintained DPM removal caused an enriched CaSO4 deposition on the plasma-catalytic reactor, which further enhanced DPM oxidation efficiency. Thus, a sustained DPM removal performance over long term could be ensured.

Graphical abstractDownload high-res image (228KB)Download full-size image