| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465052 | Chemical Engineering Journal | 2017 | 7 Pages |

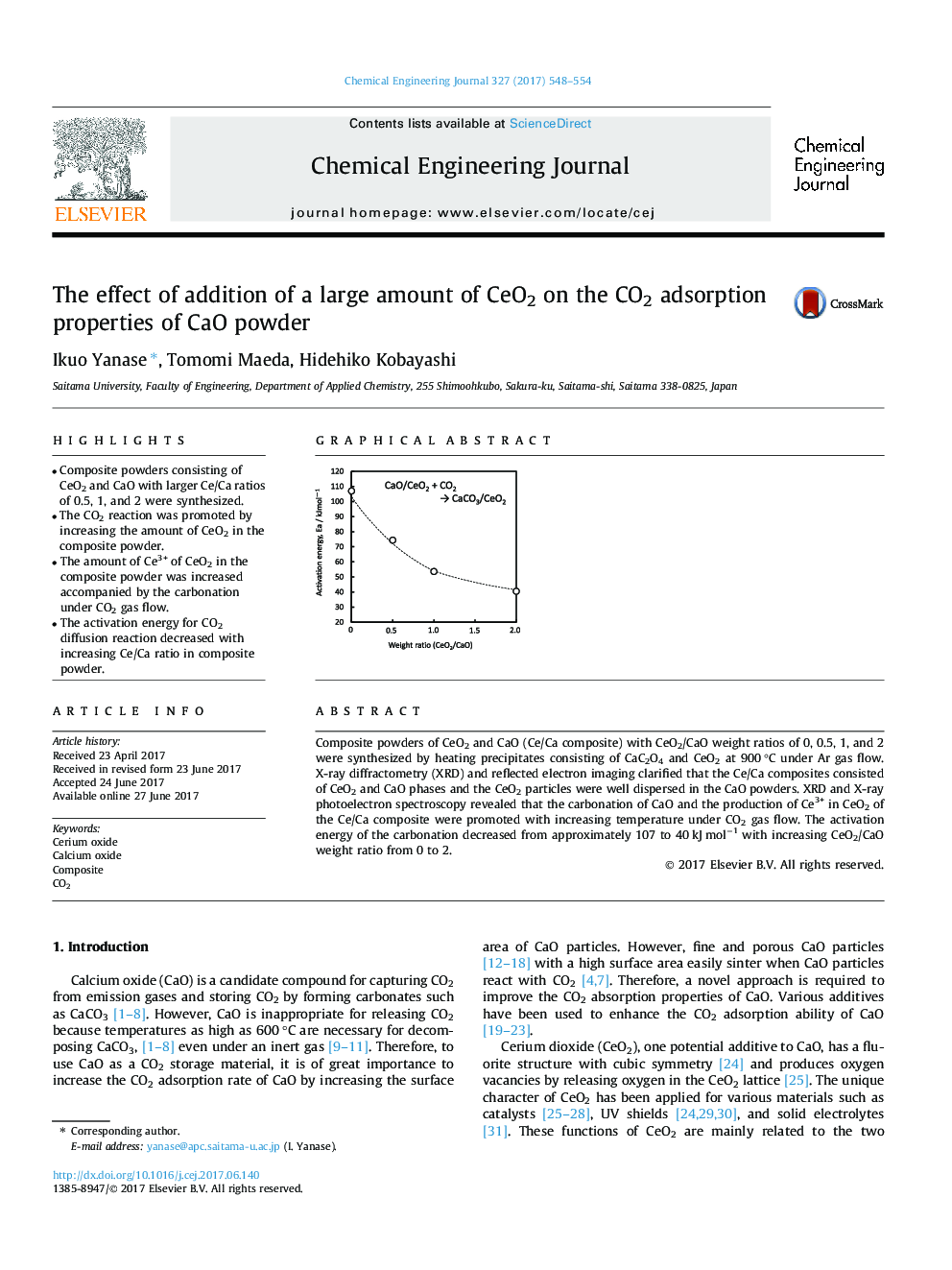

â¢Composite powders consisting of CeO2 and CaO with larger Ce/Ca ratios of 0.5, 1, and 2 were synthesized.â¢The CO2 reaction was promoted by increasing the amount of CeO2 in the composite powder.â¢The amount of Ce3+ of CeO2 in the composite powder was increased accompanied by the carbonation under CO2 gas flow.â¢The activation energy for CO2 diffusion reaction decreased with increasing Ce/Ca ratio in composite powder.

Composite powders of CeO2 and CaO (Ce/Ca composite) with CeO2/CaO weight ratios of 0, 0.5, 1, and 2 were synthesized by heating precipitates consisting of CaC2O4 and CeO2 at 900 °C under Ar gas flow. X-ray diffractometry (XRD) and reflected electron imaging clarified that the Ce/Ca composites consisted of CeO2 and CaO phases and the CeO2 particles were well dispersed in the CaO powders. XRD and X-ray photoelectron spectroscopy revealed that the carbonation of CaO and the production of Ce3+ in CeO2 of the Ce/Ca composite were promoted with increasing temperature under CO2 gas flow. The activation energy of the carbonation decreased from approximately 107 to 40 kJ molâ1 with increasing CeO2/CaO weight ratio from 0 to 2.

Graphical abstractDownload high-res image (42KB)Download full-size image