| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465089 | Chemical Engineering Journal | 2017 | 9 Pages |

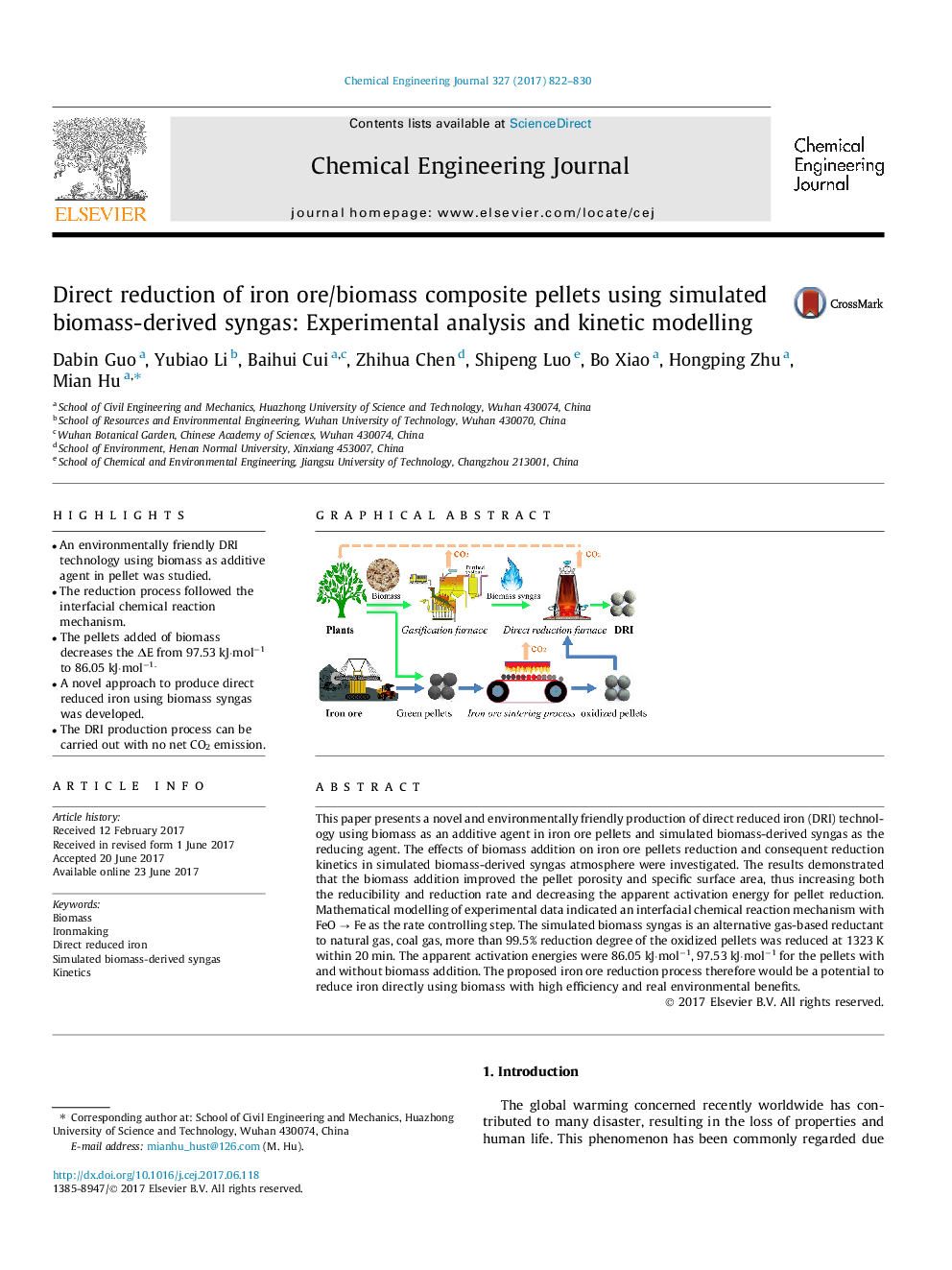

â¢An environmentally friendly DRI technology using biomass as additive agent in pellet was studied.â¢The reduction process followed the interfacial chemical reaction mechanism.â¢The pellets added of biomass decreases the ÎE from 97.53 kJ·molâ1 to 86.05 kJ·molâ1.â¢A novel approach to produce direct reduced iron using biomass syngas was developed.â¢The DRI production process can be carried out with no net CO2 emission.

This paper presents a novel and environmentally friendly production of direct reduced iron (DRI) technology using biomass as an additive agent in iron ore pellets and simulated biomass-derived syngas as the reducing agent. The effects of biomass addition on iron ore pellets reduction and consequent reduction kinetics in simulated biomass-derived syngas atmosphere were investigated. The results demonstrated that the biomass addition improved the pellet porosity and specific surface area, thus increasing both the reducibility and reduction rate and decreasing the apparent activation energy for pellet reduction. Mathematical modelling of experimental data indicated an interfacial chemical reaction mechanism with FeO â Fe as the rate controlling step. The simulated biomass syngas is an alternative gas-based reductant to natural gas, coal gas, more than 99.5% reduction degree of the oxidized pellets was reduced at 1323 K within 20 min. The apparent activation energies were 86.05 kJ·molâ1, 97.53 kJ·molâ1 for the pellets with and without biomass addition. The proposed iron ore reduction process therefore would be a potential to reduce iron directly using biomass with high efficiency and real environmental benefits.

Graphical abstractDownload high-res image (207KB)Download full-size image