| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465148 | Chemical Engineering Journal | 2017 | 13 Pages |

â¢Numerical study of non-catalytic natural gas reforming under HT/HP conditions.â¢Validation of the numerical results against semi-industrial test plant experiments.â¢Comparison of EDC and FPV approaches for turbulence-chemistry interaction modeling.â¢The models applicability was discussed in terms of flame and reactor characteristics.

The non-catalytic reforming of natural gas to syngas was studied numerically. The numerical simulations focused on the Virtuhcon Benchmark, which is a set of experimental data based on the semi-industrial scale test plant HP POX (high-pressure partial oxidation). The experimental data comprises reactor characteristics such as product gas composition and wall temperatures across the reactor for temperatures between 1473 and 1673Â K and pressures between 50 and 70Â bar(g), and optically estimated flame characteristics such as flame length and width. For turbulence-chemistry interactions, the widely used Eddy Dissipation Concept model and an advanced Flamelet/Progress-variable-based approach developed for POX processes were applied. Contrary to standard Flamelet approaches, the advanced model can describe correctly both the reaction zone and the comparatively slow chemical processes in the almost homogeneous post-flame zone. Based on the experimental data, the applicability of the different numerical models will be discussed carefully. In contrast to several literature work, the model evaluation is based not only on global reactor characteristics, but also on optical flame analyses from inside of the semi-industrial test plant, which allows to evaluate the capability of the numerical model to predict local reactive flow effects inside industrial HP/HT processes. The results reveal that both approaches allow a reliable prediction of the syngas composition, flame length, and flame width. With respect to the outlet temperature, the Eddy Dissipation Concept tends to overpredict the resulting temperature, or, from a different point of view, to underpredict the progress of the endothermic reforming conversion processes.

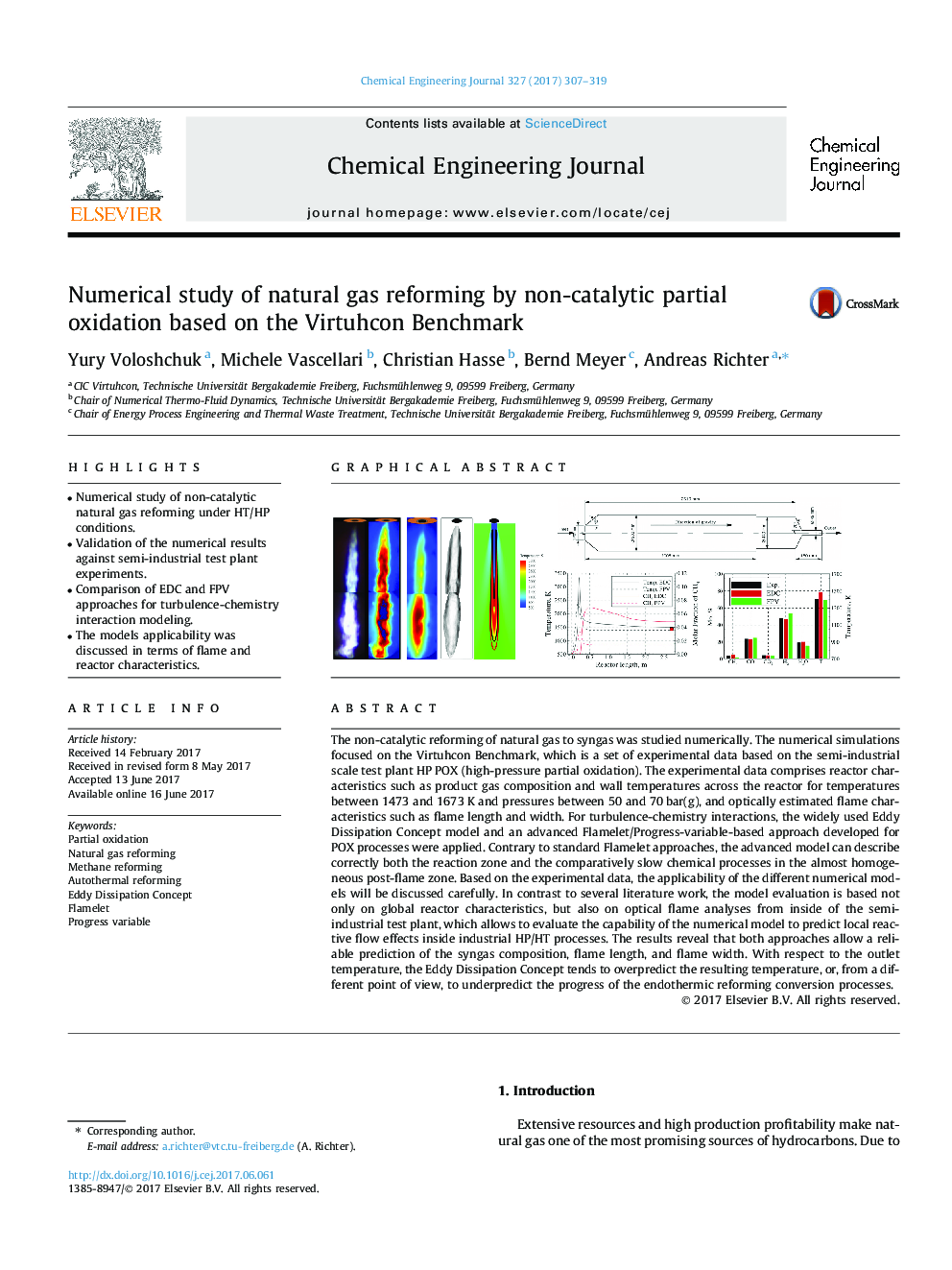

Graphical abstractDownload high-res image (210KB)Download full-size image