| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465718 | Chemical Engineering Journal | 2017 | 13 Pages |

â¢Concept of integrating CO2 capture and its conversion in the same unit is proved.â¢A multifunctional reactor for CO2 capture and conversion to CH4 is tested.â¢Captured CO2 could be completely converted to CH4.â¢Reactive regeneration improves sorbent sorption capacity and desorption kinetics.â¢The maximum CH4 productivity obtained under cyclic operation is 2.36 mol/(kg·h).

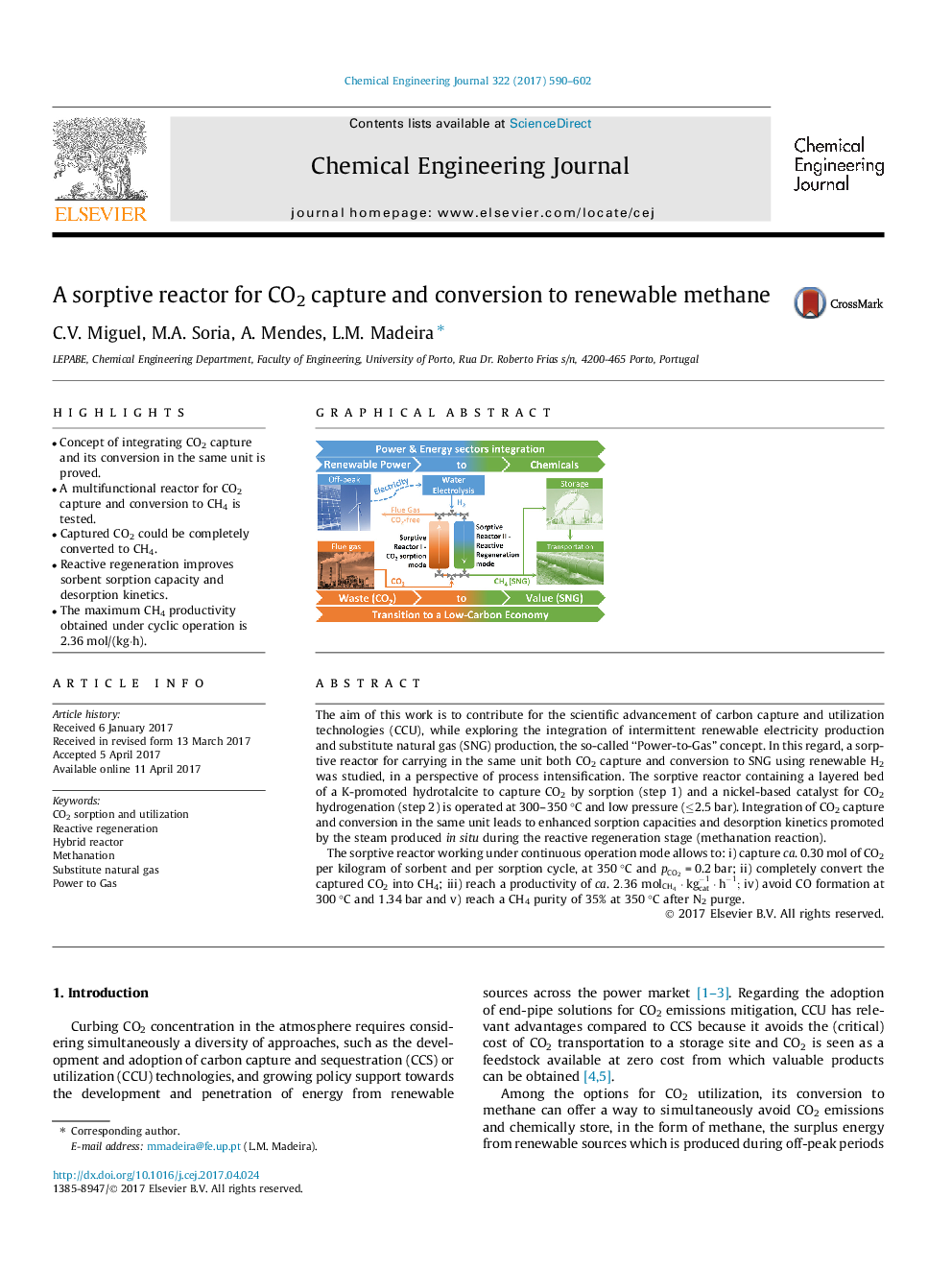

The aim of this work is to contribute for the scientific advancement of carbon capture and utilization technologies (CCU), while exploring the integration of intermittent renewable electricity production and substitute natural gas (SNG) production, the so-called “Power-to-Gas” concept. In this regard, a sorptive reactor for carrying in the same unit both CO2 capture and conversion to SNG using renewable H2 was studied, in a perspective of process intensification. The sorptive reactor containing a layered bed of a K-promoted hydrotalcite to capture CO2 by sorption (step 1) and a nickel-based catalyst for CO2 hydrogenation (step 2) is operated at 300-350 °C and low pressure (â¤2.5 bar). Integration of CO2 capture and conversion in the same unit leads to enhanced sorption capacities and desorption kinetics promoted by the steam produced in situ during the reactive regeneration stage (methanation reaction).The sorptive reactor working under continuous operation mode allows to: i) capture ca. 0.30 mol of CO2 per kilogram of sorbent and per sorption cycle, at 350 °C and pCO2 = 0.2 bar; ii) completely convert the captured CO2 into CH4; iii) reach a productivity of ca. 2.36molCH4·kgcat-1·h-1; iv) avoid CO formation at 300 °C and 1.34 bar and v) reach a CH4 purity of 35% at 350 °C after N2 purge.

Graphical abstractDownload high-res image (108KB)Download full-size image