| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465731 | Chemical Engineering Journal | 2017 | 12 Pages |

â¢Superhydrophobic nanocomposite metal coatings from recycled and non-toxic polymers.â¢Wear abrasion resistant superhydrophobic high impact polystyrene nanocomposites.â¢Tribological and wear abrasion properties can be tuned by thermal annealing.â¢Application process can be easily scaled-up.

Superhydrophobic and wear abrasion resistant high impact polystyrene (HIPS)/silica nanocomposite coatings for metal surfaces have been produced by spray. An environmentally friendly perfluorinated acrylic copolymer (PFAC) primer coating layer was applied first, in order to enhance adhesion with the substrate and prolong abrasion resistance. The best nanocomposite composition was found to be 50% silica nanoparticles with respect to HIPS by weight. This coating displayed the lowest friction coefficient compared to other nanocomposites with lower or higher silica concentrations. Tribological experiments on the best performing nanocomposites indicated that wear tracks or marks had no debris, cracks or complete material removal. Furthermore, Taber® abrasion tests confirmed tribological findings and showed that the best nanocomposites resisted superhydrophobic degradation up to 35 continuous linear abrasion cycles (15Â kPa). Nanocomposites made with general purpose polystyrene instead of HIPS could only resist up to 15 Taber® abrasion cycles. The reason was attributed to the mechanical energy dissipation capability of rubber domains in HIPS. Thermal annealing of the coatings had a deterministic effect on the durability of the coatings against wear induced loss of superhydrophobicity. Annealed and non-annealed coatings were characterized by Fourier transform infrared and X-ray photoelectron spectroscopy. Due to ease of fabrication, resultant mechanical robustness, use of non-toxic materials, and low-cost industrial scale availability of HIPS, nanoparticles and the primer polymer, these coatings can be effortlessly transformed into larger scale non-wettable protective treatments for metals.

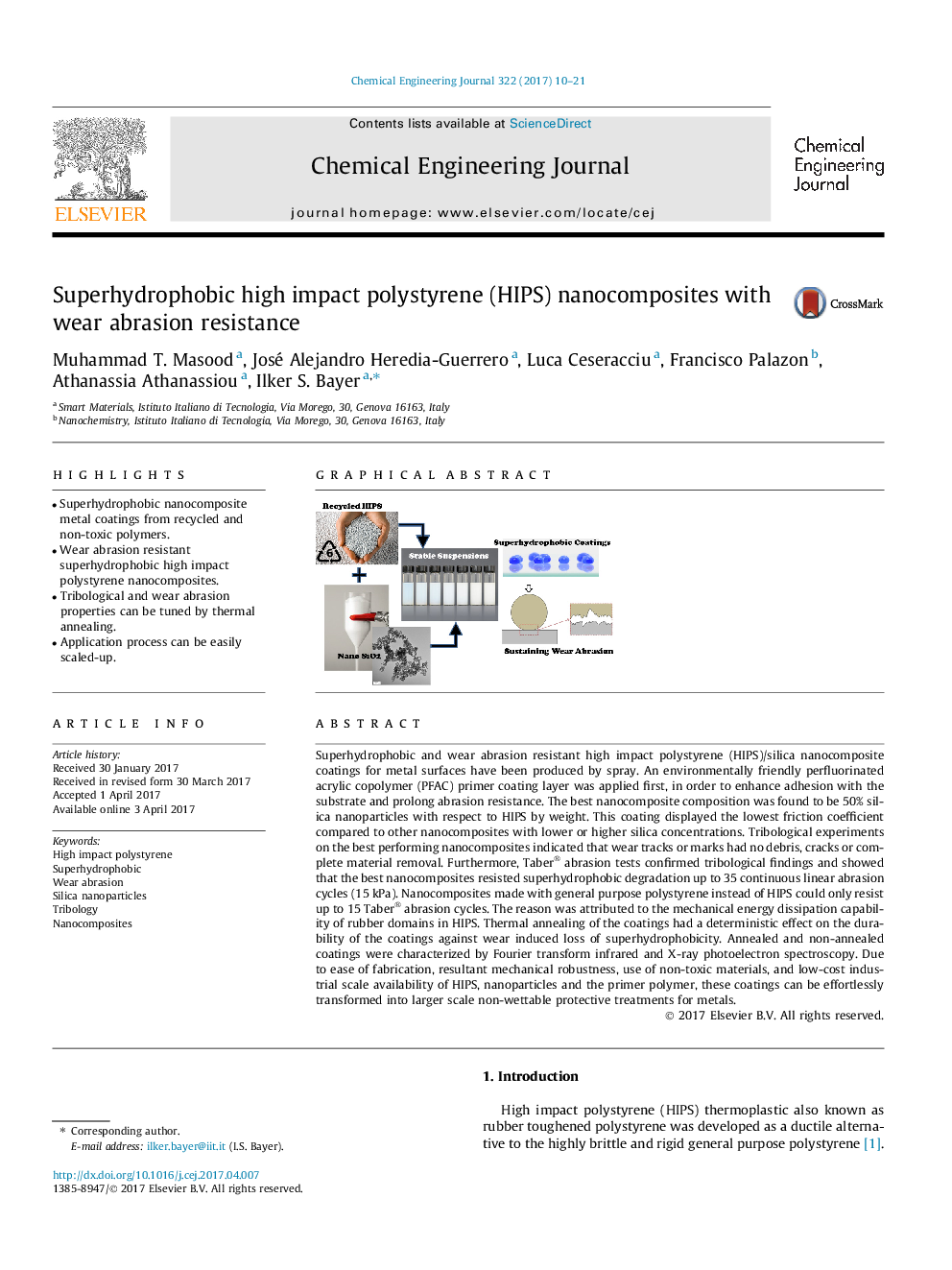

Graphical abstractDownload high-res image (83KB)Download full-size image