| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465741 | Chemical Engineering Journal | 2017 | 10 Pages |

•We prepared superhydrophobic and superoleophilic nickel foam by one-step spraying.•The 3D FPUH coated nickel foam could continuously collect the oil.•The 3D FPUH coated nickel foam showed excellent superhydrophobic durability and high oil/water separation efficiency.•After heat treatment, the static WCA of nickel foam could be restored to 150°.

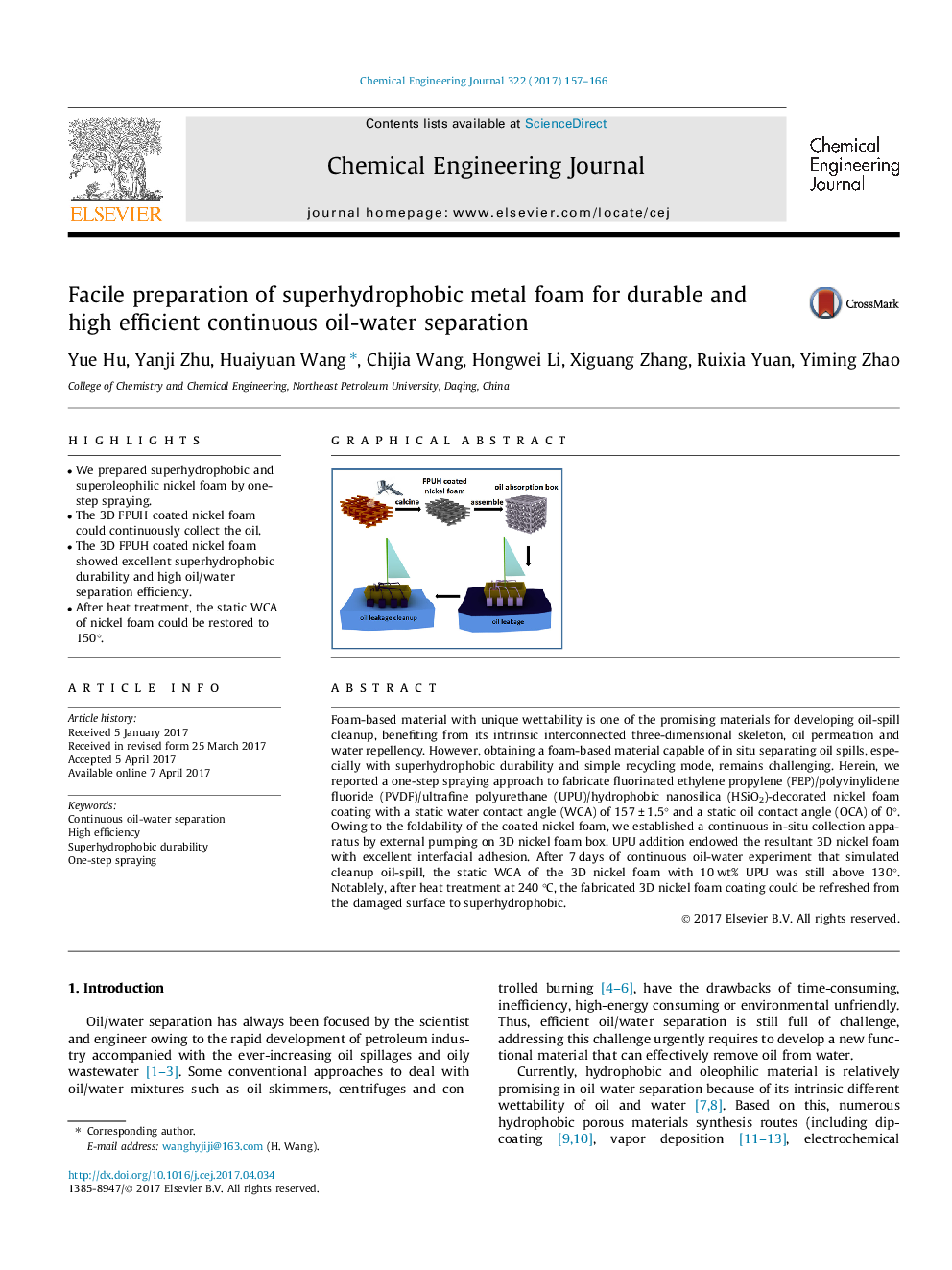

Foam-based material with unique wettability is one of the promising materials for developing oil-spill cleanup, benefiting from its intrinsic interconnected three-dimensional skeleton, oil permeation and water repellency. However, obtaining a foam-based material capable of in situ separating oil spills, especially with superhydrophobic durability and simple recycling mode, remains challenging. Herein, we reported a one-step spraying approach to fabricate fluorinated ethylene propylene (FEP)/polyvinylidene fluoride (PVDF)/ultrafine polyurethane (UPU)/hydrophobic nanosilica (HSiO2)-decorated nickel foam coating with a static water contact angle (WCA) of 157 ± 1.5° and a static oil contact angle (OCA) of 0°. Owing to the foldability of the coated nickel foam, we established a continuous in-situ collection apparatus by external pumping on 3D nickel foam box. UPU addition endowed the resultant 3D nickel foam with excellent interfacial adhesion. After 7 days of continuous oil-water experiment that simulated cleanup oil-spill, the static WCA of the 3D nickel foam with 10 wt% UPU was still above 130°. Notablely, after heat treatment at 240 °C, the fabricated 3D nickel foam coating could be refreshed from the damaged surface to superhydrophobic.

Graphical abstractFigure optionsDownload full-size imageDownload high-quality image (60 K)Download as PowerPoint slide