| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6465824 | Chemical Engineering Journal | 2017 | 8 Pages |

â¢First study on activated carbon from CCA-treated wood production.â¢Fuel gas from pyrolysis process presented high H2 concentration.â¢More than 70% of arsenic was retained in the char and activated carbon.â¢Copper and chromium from CCA-treated wood improved the CO2 adsorption.

The disposal of eucalyptus poles used in the electricity network distribution is considered a potential contamination to the environment due to the chromated copper arsenate (CCA) used as a wood preservative. The thermochemical process can be an alternative to this toxic waste disposal. In this work, the slow pyrolysis of CCA-treated wood followed by the production and application of activated carbon was proposed. Metal retention (ICP-OES), concentration of non-condensable gases produced in the pyrolysis process (via GC), as well as the capacity of activated carbon on CO2 adsorption (via TGA) were investigated. The highest formation rate of non-condensable gases was observed at 500 °C, while the maximum H2 concentration was at 700 °C. The char obtained in the pyrolysis was chemically treated with H3PO4 and activated in CO2 flow. The pore size distribution of activated carbons showed pore sizes lower than 1 nm. The activated carbons showed a CO2 adsorption capacity of 70-83 mg/g. The presence of chromium and copper may have influenced the CO2 adsorption. The fast adsorption and desorption showed by the activated carbon produced from CCA-treated wood is interesting to systems that operate in short-time cycles, as pressure swing adsorption (PSA). The reuse of CCA-treated wood for activated carbon production and its application in the CO2 adsorption could be a solution to minimize the environmental damage caused by this waste.

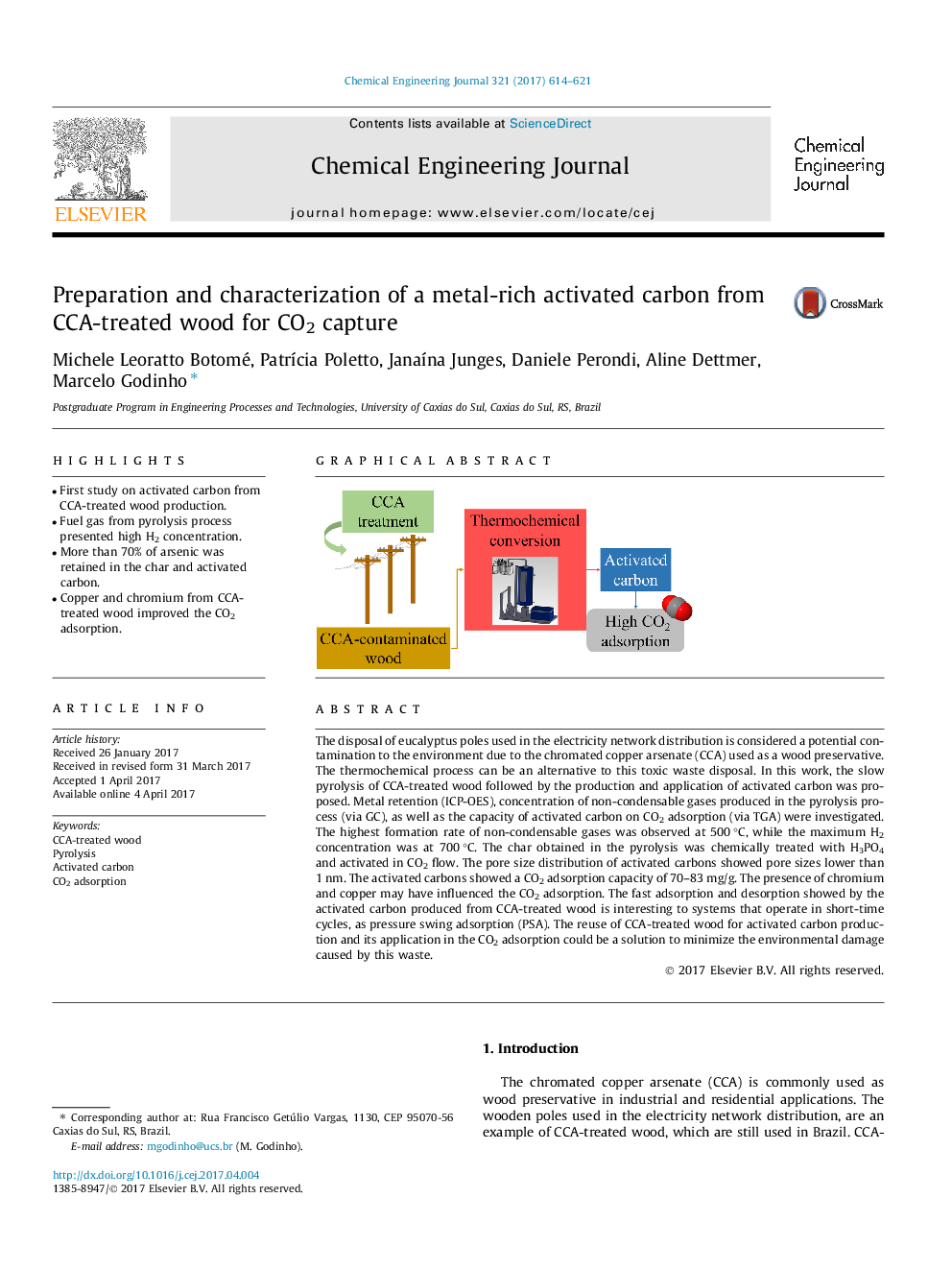

Graphical abstractDownload high-res image (157KB)Download full-size image