| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6466130 | Chemical Engineering Journal | 2017 | 8 Pages |

â¢Undivided cell evidenced to prepare peroxymonophosphoric acid.â¢Ti cathode favored to prepare high concentration of peroxymonophosphoric acid.â¢High concentration of peroxymonophosphoric at equal cathode size seems to be influence of OH.â¢With the 1.71% current efficiency, 30 ppm of acetaldehyde was removed successfully.

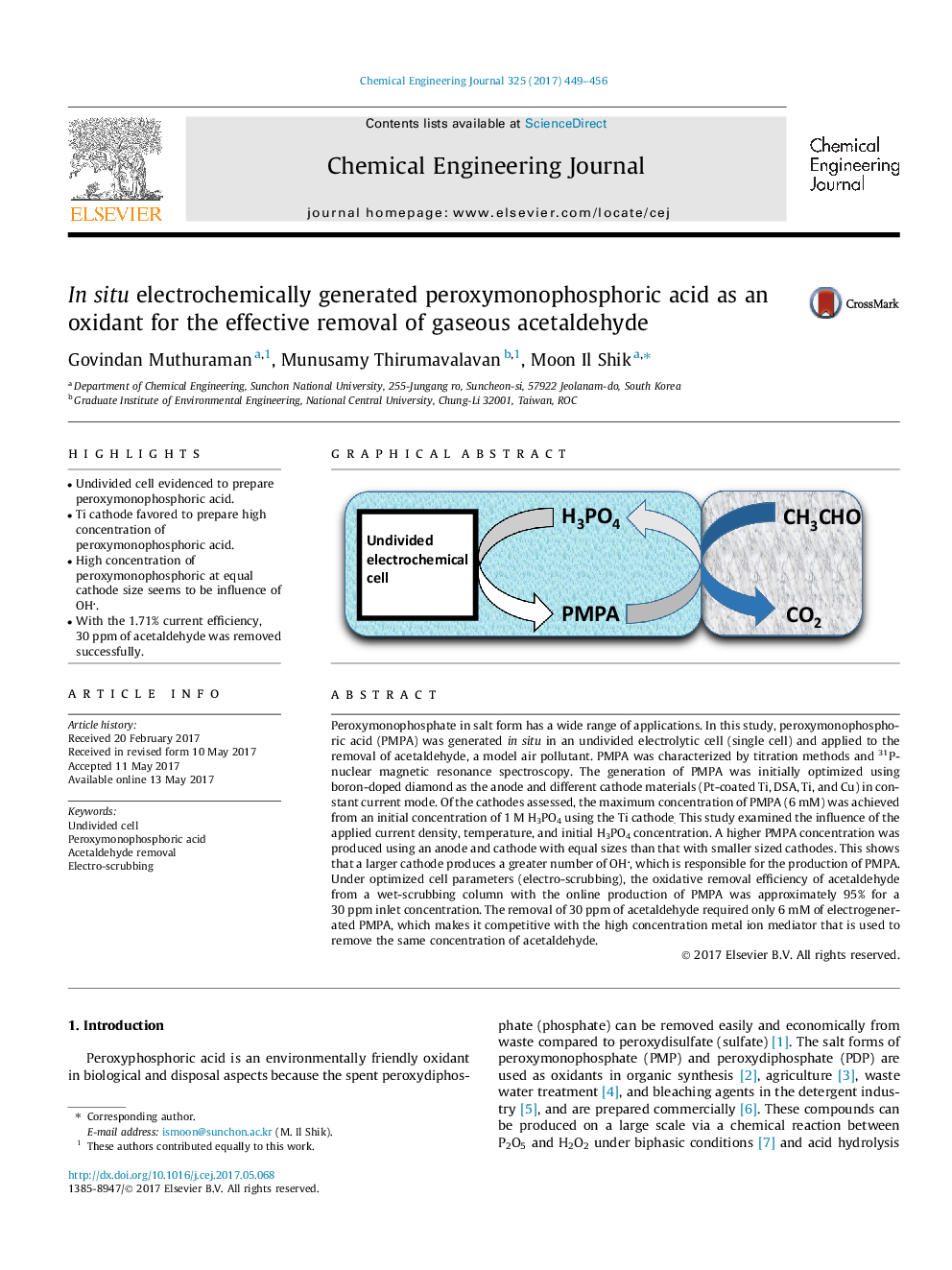

Peroxymonophosphate in salt form has a wide range of applications. In this study, peroxymonophosphoric acid (PMPA) was generated in situ in an undivided electrolytic cell (single cell) and applied to the removal of acetaldehyde, a model air pollutant. PMPA was characterized by titration methods and 31P-nuclear magnetic resonance spectroscopy. The generation of PMPA was initially optimized using boron-doped diamond as the anode and different cathode materials (Pt-coated Ti, DSA, Ti, and Cu) in constant current mode. Of the cathodes assessed, the maximum concentration of PMPA (6Â mM) was achieved from an initial concentration of 1Â M H3PO4 using the Ti cathode. This study examined the influence of the applied current density, temperature, and initial H3PO4 concentration. A higher PMPA concentration was produced using an anode and cathode with equal sizes than that with smaller sized cathodes. This shows that a larger cathode produces a greater number of OH, which is responsible for the production of PMPA. Under optimized cell parameters (electro-scrubbing), the oxidative removal efficiency of acetaldehyde from a wet-scrubbing column with the online production of PMPA was approximately 95% for a 30Â ppm inlet concentration. The removal of 30Â ppm of acetaldehyde required only 6Â mM of electrogenerated PMPA, which makes it competitive with the high concentration metal ion mediator that is used to remove the same concentration of acetaldehyde.

Graphical abstractDownload high-res image (119KB)Download full-size image