| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 148350 | 456409 | 2014 | 8 صفحه PDF | دانلود رایگان |

• Combustion process in TiO2–Mg–Ca(OH)2 system is investigated under argon pressure.

• The maximum temperature was between 1650 and 1690 °C during the combustion. was measured.

• Ti powder with 1.5 wt% of oxygen was obtained after acid-leaching of as-combusted sample.

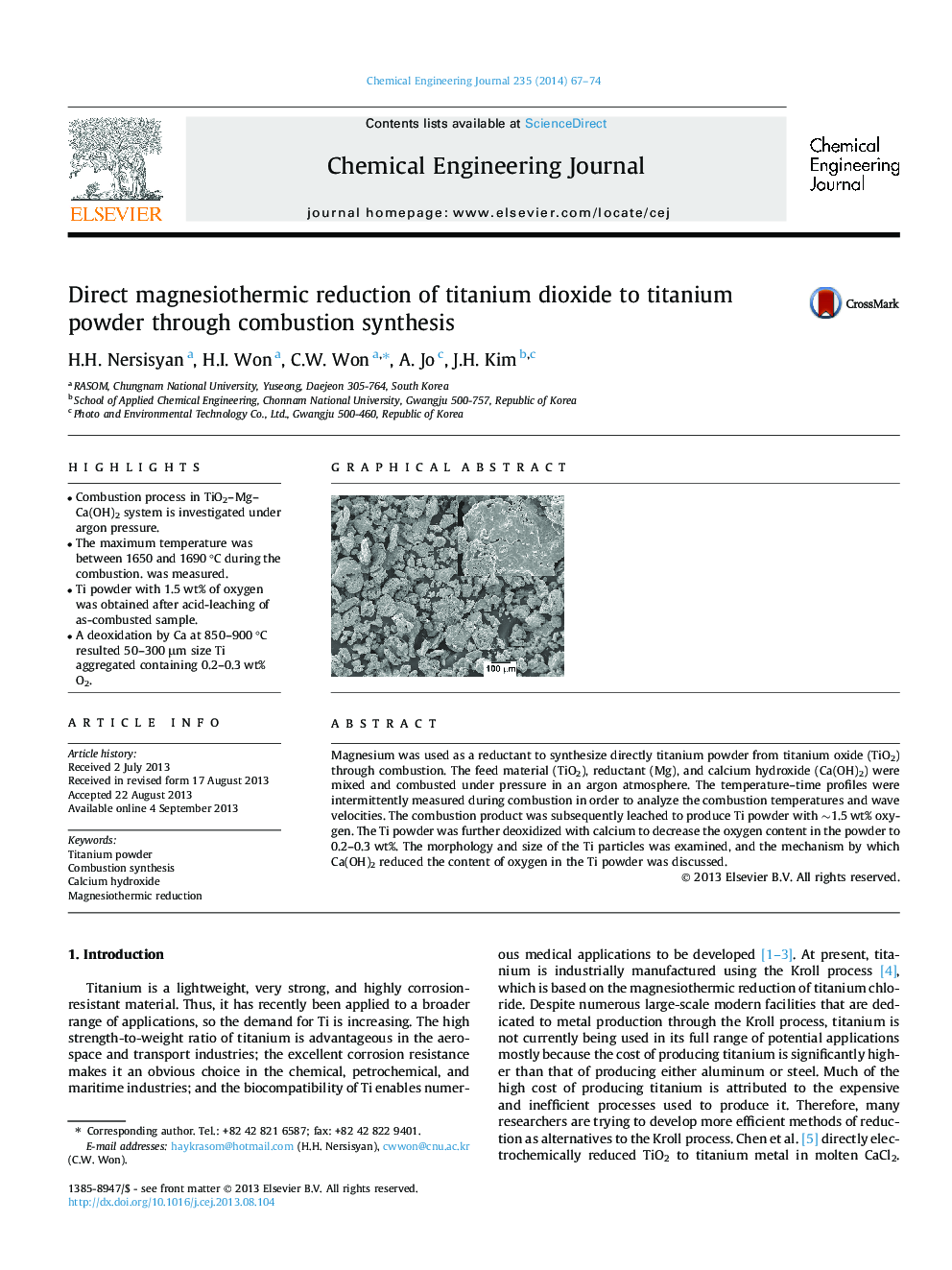

• A deoxidation by Ca at 850–900 °C resulted 50–300 μm size Ti aggregated containing 0.2–0.3 wt% O2.

Magnesium was used as a reductant to synthesize directly titanium powder from titanium oxide (TiO2) through combustion. The feed material (TiO2), reductant (Mg), and calcium hydroxide (Ca(OH)2) were mixed and combusted under pressure in an argon atmosphere. The temperature–time profiles were intermittently measured during combustion in order to analyze the combustion temperatures and wave velocities. The combustion product was subsequently leached to produce Ti powder with ∼1.5 wt% oxygen. The Ti powder was further deoxidized with calcium to decrease the oxygen content in the powder to 0.2–0.3 wt%. The morphology and size of the Ti particles was examined, and the mechanism by which Ca(OH)2 reduced the content of oxygen in the Ti powder was discussed.

Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 235, 1 January 2014, Pages 67–74