| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 1564777 | 1514177 | 2016 | 5 صفحه PDF | دانلود رایگان |

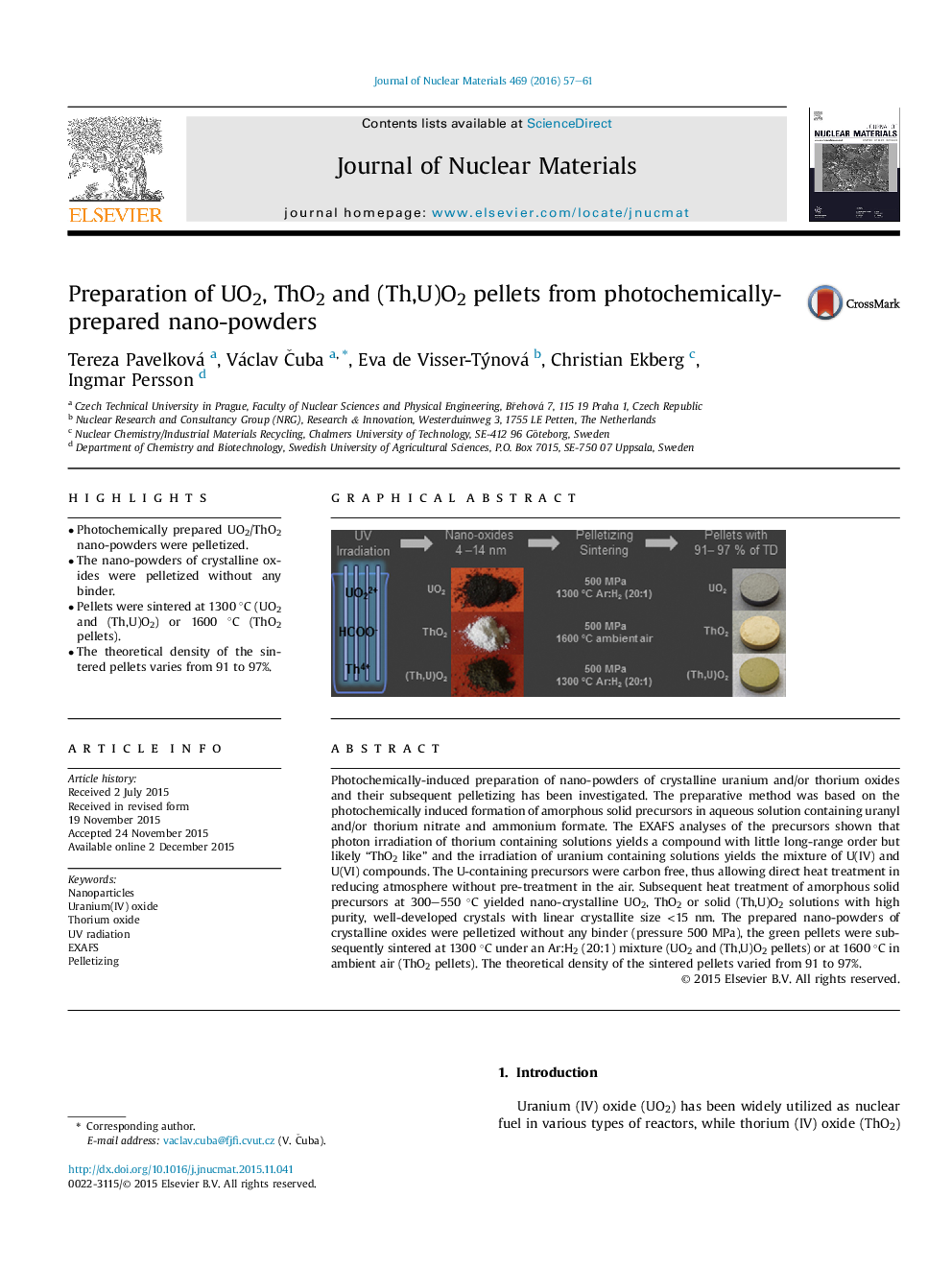

• Photochemically prepared UO2/ThO2 nano-powders were pelletized.

• The nano-powders of crystalline oxides were pelletized without any binder.

• Pellets were sintered at 1300 °C (UO2 and (Th,U)O2) or 1600 °C (ThO2 pellets).

• The theoretical density of the sintered pellets varies from 91 to 97%.

Photochemically-induced preparation of nano-powders of crystalline uranium and/or thorium oxides and their subsequent pelletizing has been investigated. The preparative method was based on the photochemically induced formation of amorphous solid precursors in aqueous solution containing uranyl and/or thorium nitrate and ammonium formate. The EXAFS analyses of the precursors shown that photon irradiation of thorium containing solutions yields a compound with little long-range order but likely “ThO2 like” and the irradiation of uranium containing solutions yields the mixture of U(IV) and U(VI) compounds. The U-containing precursors were carbon free, thus allowing direct heat treatment in reducing atmosphere without pre-treatment in the air. Subsequent heat treatment of amorphous solid precursors at 300–550 °C yielded nano-crystalline UO2, ThO2 or solid (Th,U)O2 solutions with high purity, well-developed crystals with linear crystallite size <15 nm. The prepared nano-powders of crystalline oxides were pelletized without any binder (pressure 500 MPa), the green pellets were subsequently sintered at 1300 °C under an Ar:H2 (20:1) mixture (UO2 and (Th,U)O2 pellets) or at 1600 °C in ambient air (ThO2 pellets). The theoretical density of the sintered pellets varied from 91 to 97%.

Figure optionsDownload as PowerPoint slide

Journal: Journal of Nuclear Materials - Volume 469, February 2016, Pages 57–61