| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 1698975 | 1519310 | 2016 | 5 صفحه PDF | دانلود رایگان |

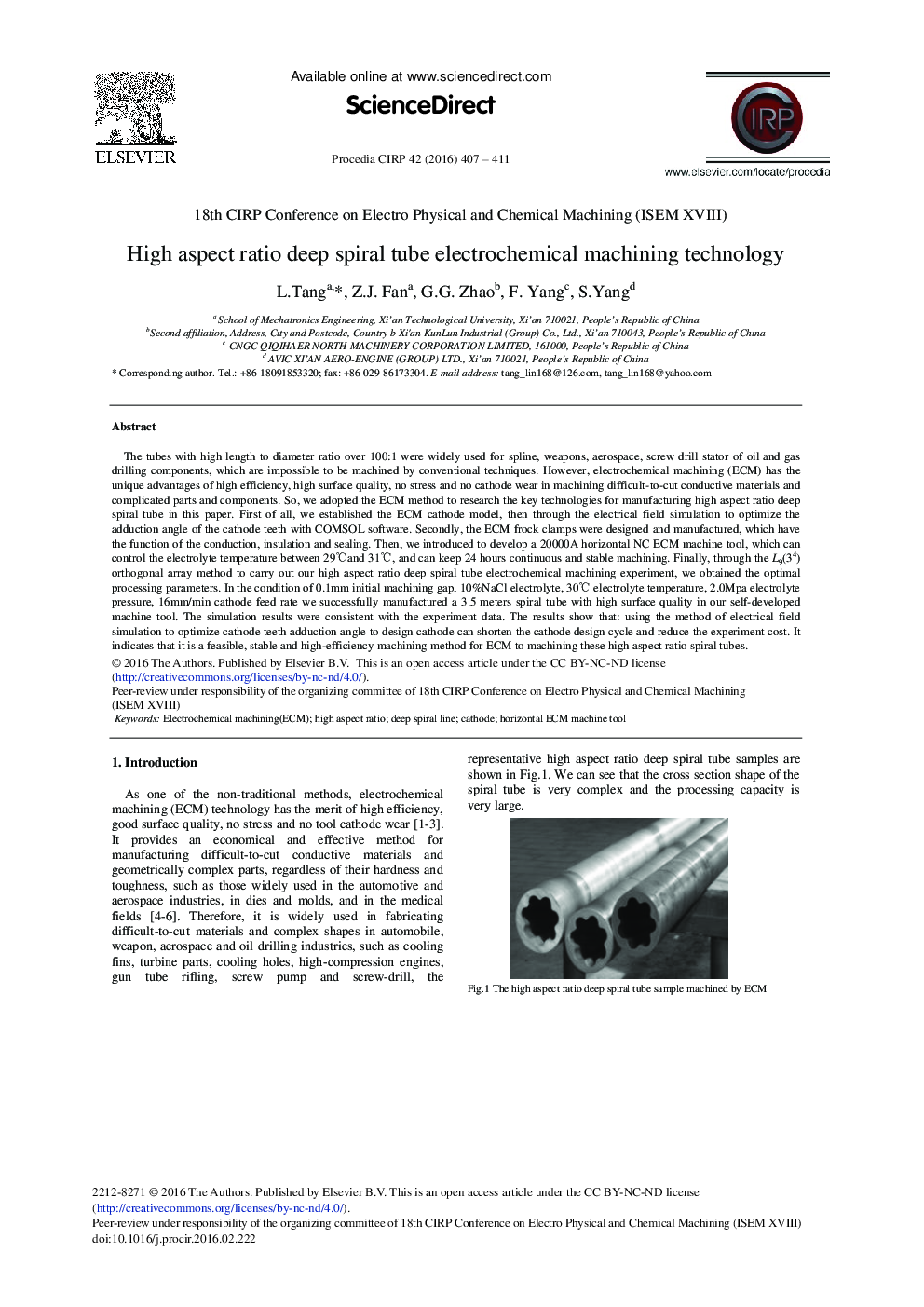

The tubes with high length to diameter ratio over 100:1 were widely used for spline, weapons, aerospace, screw drill stator of oil and gas drilling components, which are impossible to be machined by conventional techniques. However, electrochemical machining (ECM) has the unique advantages of high efficiency, high surface quality, no stress and no cathode wear in machining difficult-to-cut conductive materials and complicated parts and components. So, we adopted the ECM method to research the key technologies for manufacturing high aspect ratio deep spiral tube in this paper. First of all, we established the ECM cathode model, then through the electrical field simulation to optimize the adduction angle of the cathode teeth with COMSOL software. Secondly, the ECM frock clamps were designed and manufactured, which have the function of the conduction, insulation and sealing. Then, we introduced to develop a 20000A horizontal NC ECM machine tool, which can control the electrolyte temperature between 29°C and 31°C, and can keep 24 hours continuous and stable machining. Finally, through the L9(34) orthogonal array method to carry out our high aspect ratio deep spiral tube electrochemical machining experiment, we obtained the optimal processing parameters. In the condition of 0.1 mm initial machining gap, 10%NaCl electrolyte, 30°C electrolyte temperature, 2.0 Mpa electrolyte pressure, 16 mm/min cathode feed rate we successfully manufactured a 3.5 meters spiral tube with high surface quality in our self-developed machine tool. The simulation results were consistent with the experiment data. The results show that: using the method of electrical field simulation to optimize cathode teeth adduction angle to design cathode can shorten the cathode design cycle and reduce the experiment cost. It indicates that it is a feasible, stable and high-efficiency machining method for ECM to machining these high aspect ratio spiral tubes.

Journal: Procedia CIRP - Volume 42, 2016, Pages 407-411