| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 594020 | 1453959 | 2012 | 7 صفحه PDF | دانلود رایگان |

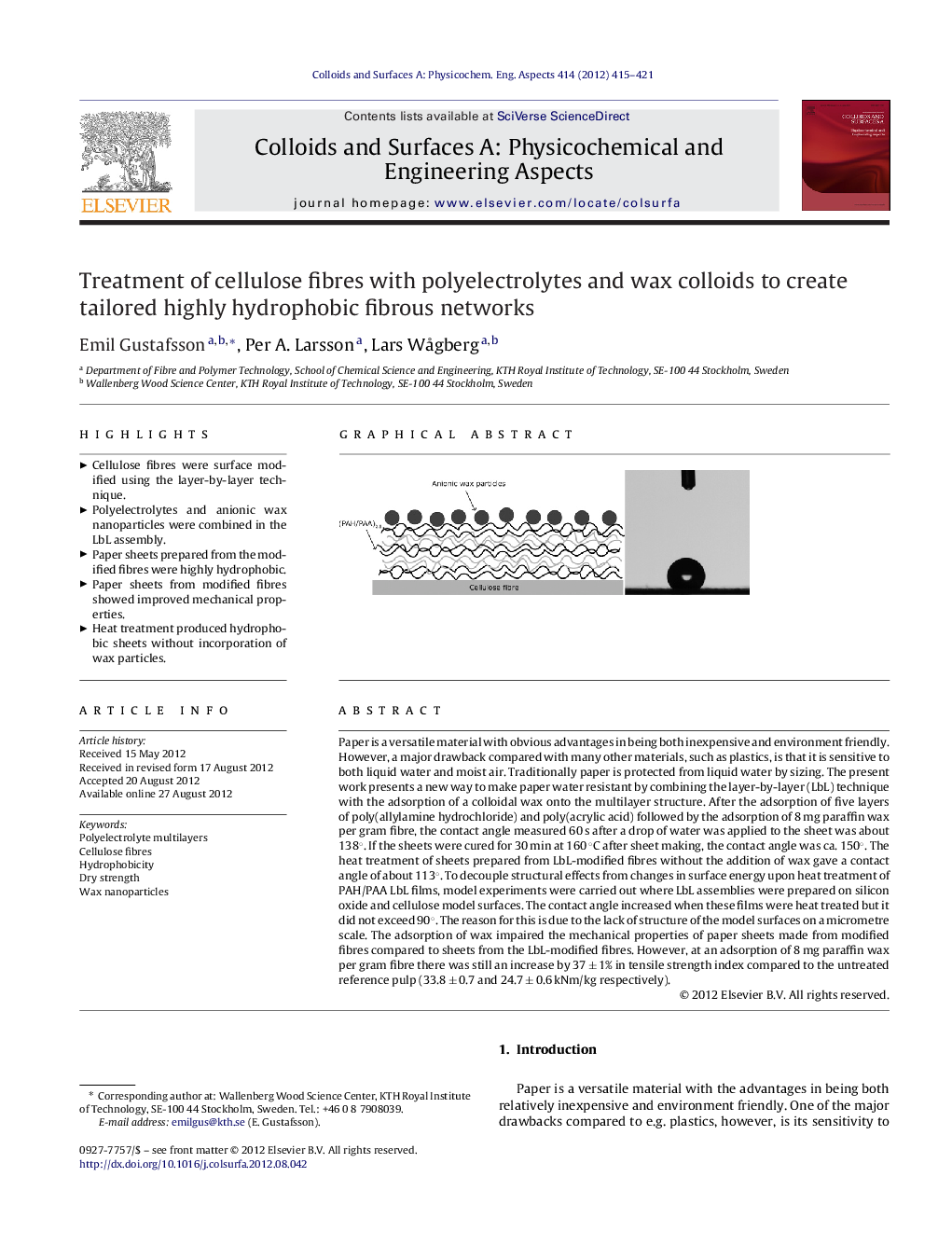

Paper is a versatile material with obvious advantages in being both inexpensive and environment friendly. However, a major drawback compared with many other materials, such as plastics, is that it is sensitive to both liquid water and moist air. Traditionally paper is protected from liquid water by sizing. The present work presents a new way to make paper water resistant by combining the layer-by-layer (LbL) technique with the adsorption of a colloidal wax onto the multilayer structure. After the adsorption of five layers of poly(allylamine hydrochloride) and poly(acrylic acid) followed by the adsorption of 8 mg paraffin wax per gram fibre, the contact angle measured 60 s after a drop of water was applied to the sheet was about 138°. If the sheets were cured for 30 min at 160 °C after sheet making, the contact angle was ca. 150°. The heat treatment of sheets prepared from LbL-modified fibres without the addition of wax gave a contact angle of about 113°. To decouple structural effects from changes in surface energy upon heat treatment of PAH/PAA LbL films, model experiments were carried out where LbL assemblies were prepared on silicon oxide and cellulose model surfaces. The contact angle increased when these films were heat treated but it did not exceed 90°. The reason for this is due to the lack of structure of the model surfaces on a micrometre scale. The adsorption of wax impaired the mechanical properties of paper sheets made from modified fibres compared to sheets from the LbL-modified fibres. However, at an adsorption of 8 mg paraffin wax per gram fibre there was still an increase by 37 ± 1% in tensile strength index compared to the untreated reference pulp (33.8 ± 0.7 and 24.7 ± 0.6 kNm/kg respectively).

Figure optionsDownload as PowerPoint slideHighlights

► Cellulose fibres were surface modified using the layer-by-layer technique.

► Polyelectrolytes and anionic wax nanoparticles were combined in the LbL assembly.

► Paper sheets prepared from the modified fibres were highly hydrophobic.

► Paper sheets from modified fibres showed improved mechanical properties.

► Heat treatment produced hydrophobic sheets without incorporation of wax particles.

Journal: Colloids and Surfaces A: Physicochemical and Engineering Aspects - Volume 414, 20 November 2012, Pages 415–421