| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6466804 | 1423246 | 2017 | 8 صفحه PDF | دانلود رایگان |

- The new mixing technology “Fluid Phase Resonance mixing” is investigated.

- CFD simulations (verified by measurements) are used to optimise the process.

- Mixing time, mixing quality, and power consumption are determined.

- One best configuration is identified.

- Best configuration is as efficient as propeller stirrer.

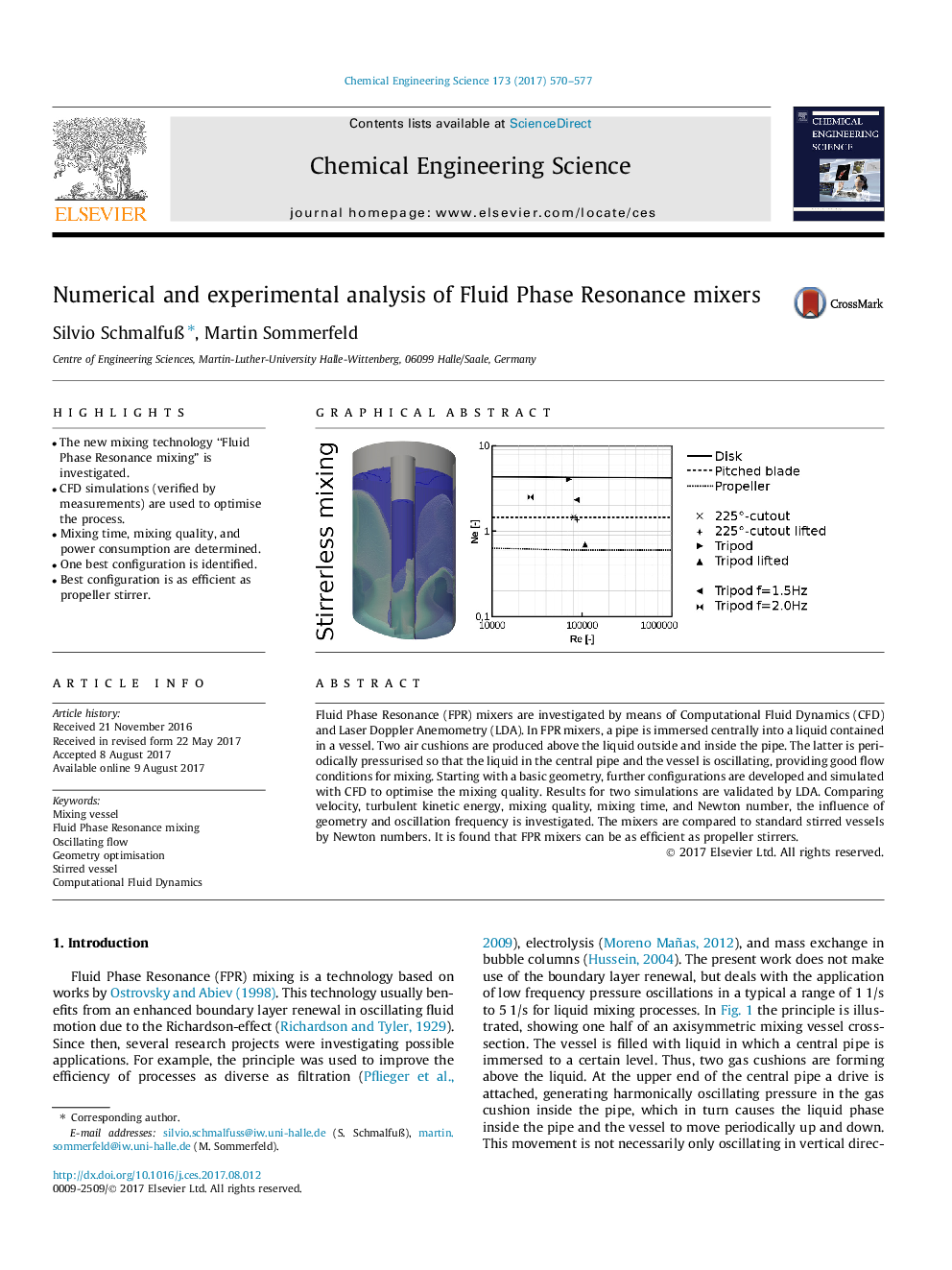

Fluid Phase Resonance (FPR) mixers are investigated by means of Computational Fluid Dynamics (CFD) and Laser Doppler Anemometry (LDA). In FPR mixers, a pipe is immersed centrally into a liquid contained in a vessel. Two air cushions are produced above the liquid outside and inside the pipe. The latter is periodically pressurised so that the liquid in the central pipe and the vessel is oscillating, providing good flow conditions for mixing. Starting with a basic geometry, further configurations are developed and simulated with CFD to optimise the mixing quality. Results for two simulations are validated by LDA. Comparing velocity, turbulent kinetic energy, mixing quality, mixing time, and Newton number, the influence of geometry and oscillation frequency is investigated. The mixers are compared to standard stirred vessels by Newton numbers. It is found that FPR mixers can be as efficient as propeller stirrers.

97

Journal: Chemical Engineering Science - Volume 173, 14 December 2017, Pages 570-577