| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6467405 | 1423257 | 2017 | 16 صفحه PDF | دانلود رایگان |

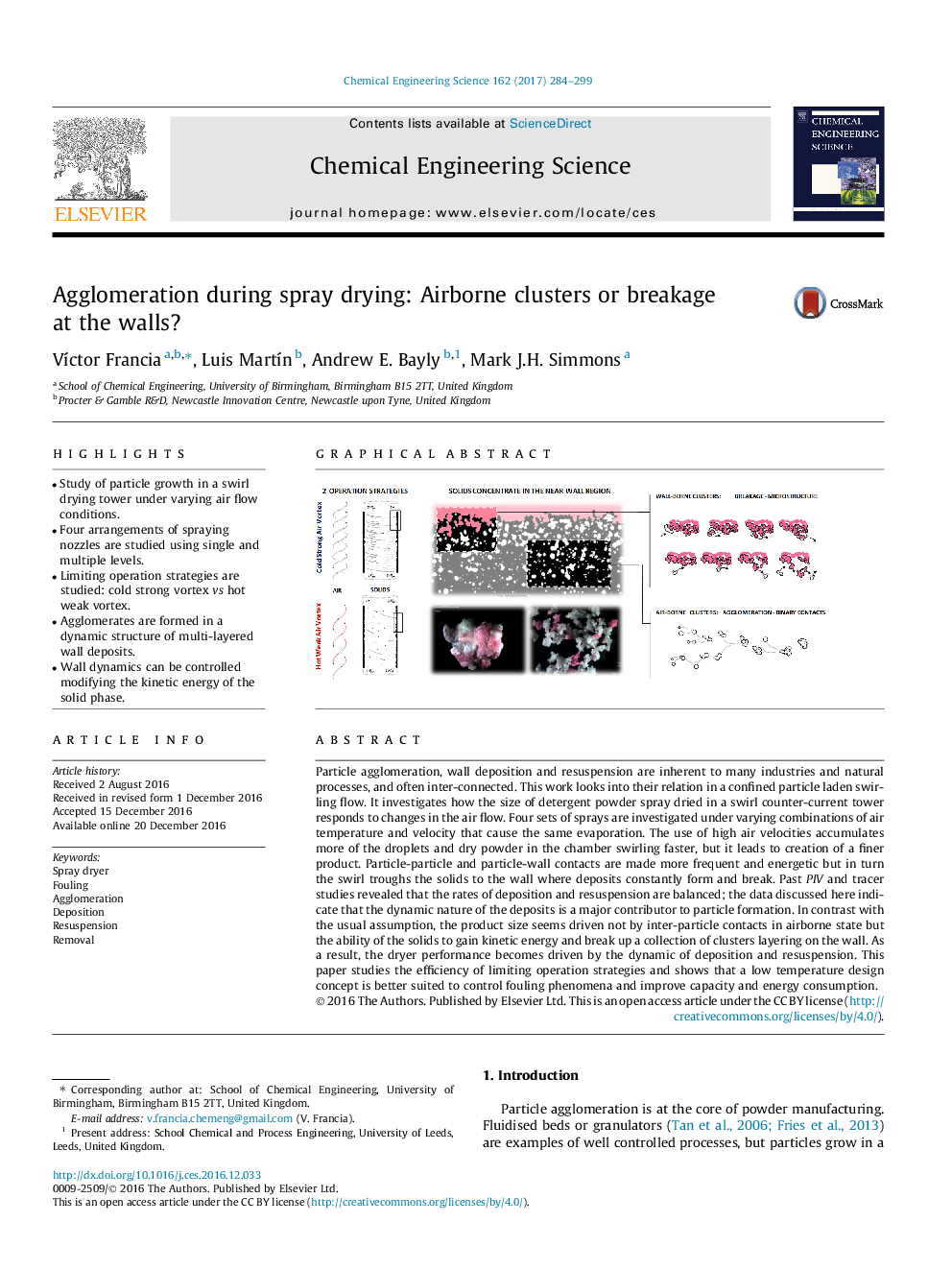

- Study of particle growth in a swirl drying tower under varying air flow conditions.

- Four arrangements of spraying nozzles are studied using single and multiple levels.

- Limiting operation strategies are studied: cold strong vortex vs hot weak vortex.

- Agglomerates are formed in a dynamic structure of multi-layered wall deposits.

- Wall dynamics can be controlled modifying the kinetic energy of the solid phase.

Particle agglomeration, wall deposition and resuspension are inherent to many industries and natural processes, and often inter-connected. This work looks into their relation in a confined particle laden swirling flow. It investigates how the size of detergent powder spray dried in a swirl counter-current tower responds to changes in the air flow. Four sets of sprays are investigated under varying combinations of air temperature and velocity that cause the same evaporation. The use of high air velocities accumulates more of the droplets and dry powder in the chamber swirling faster, but it leads to creation of a finer product. Particle-particle and particle-wall contacts are made more frequent and energetic but in turn the swirl troughs the solids to the wall where deposits constantly form and break. Past PIV and tracer studies revealed that the rates of deposition and resuspension are balanced; the data discussed here indicate that the dynamic nature of the deposits is a major contributor to particle formation. In contrast with the usual assumption, the product size seems driven not by inter-particle contacts in airborne state but the ability of the solids to gain kinetic energy and break up a collection of clusters layering on the wall. As a result, the dryer performance becomes driven by the dynamic of deposition and resuspension. This paper studies the efficiency of limiting operation strategies and shows that a low temperature design concept is better suited to control fouling phenomena and improve capacity and energy consumption.

254

Journal: Chemical Engineering Science - Volume 162, 27 April 2017, Pages 284-299