| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6467643 | 1423253 | 2017 | 17 صفحه PDF | دانلود رایگان |

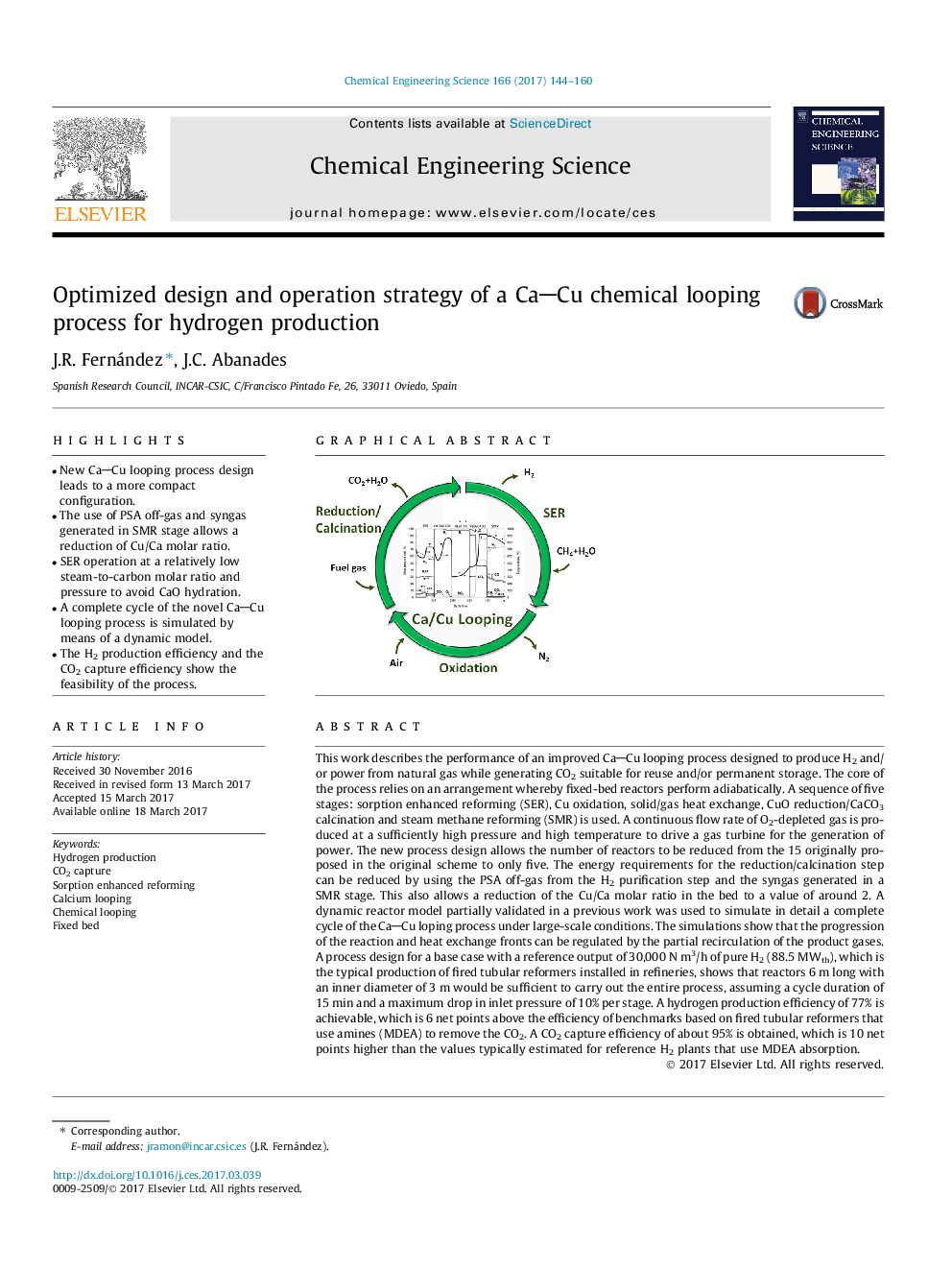

- New CaCu looping process design leads to a more compact configuration.

- The use of PSA off-gas and syngas generated in SMR stage allows a reduction of Cu/Ca molar ratio.

- SER operation at a relatively low steam-to-carbon molar ratio and pressure to avoid CaO hydration.

- A complete cycle of the novel CaCu looping process is simulated by means of a dynamic model.

- The H2 production efficiency and the CO2 capture efficiency show the feasibility of the process.

This work describes the performance of an improved CaCu looping process designed to produce H2 and/or power from natural gas while generating CO2 suitable for reuse and/or permanent storage. The core of the process relies on an arrangement whereby fixed-bed reactors perform adiabatically. A sequence of five stages: sorption enhanced reforming (SER), Cu oxidation, solid/gas heat exchange, CuO reduction/CaCO3 calcination and steam methane reforming (SMR) is used. A continuous flow rate of O2-depleted gas is produced at a sufficiently high pressure and high temperature to drive a gas turbine for the generation of power. The new process design allows the number of reactors to be reduced from the 15 originally proposed in the original scheme to only five. The energy requirements for the reduction/calcination step can be reduced by using the PSA off-gas from the H2 purification step and the syngas generated in a SMR stage. This also allows a reduction of the Cu/Ca molar ratio in the bed to a value of around 2. A dynamic reactor model partially validated in a previous work was used to simulate in detail a complete cycle of the CaCu loping process under large-scale conditions. The simulations show that the progression of the reaction and heat exchange fronts can be regulated by the partial recirculation of the product gases. A process design for a base case with a reference output of 30,000Â NÂ m3/h of pure H2 (88.5Â MWth), which is the typical production of fired tubular reformers installed in refineries, shows that reactors 6Â m long with an inner diameter of 3Â m would be sufficient to carry out the entire process, assuming a cycle duration of 15Â min and a maximum drop in inlet pressure of 10% per stage. A hydrogen production efficiency of 77% is achievable, which is 6 net points above the efficiency of benchmarks based on fired tubular reformers that use amines (MDEA) to remove the CO2. A CO2 capture efficiency of about 95% is obtained, which is 10 net points higher than the values typically estimated for reference H2 plants that use MDEA absorption.

70

Journal: Chemical Engineering Science - Volume 166, 20 July 2017, Pages 144-160