| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 709328 | 892065 | 2013 | 6 صفحه PDF | دانلود رایگان |

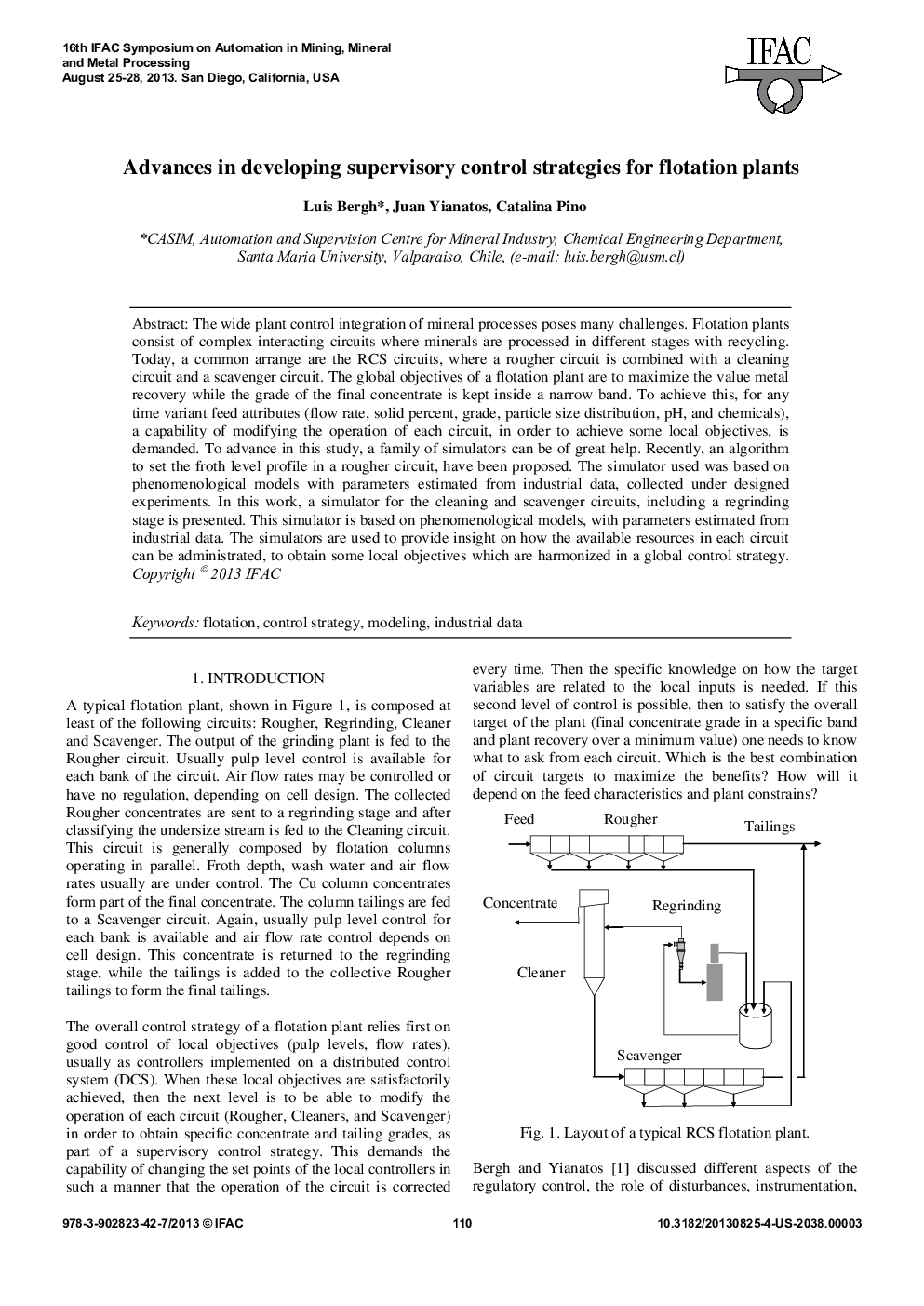

The wide plant control integration of mineral processes poses many challenges. Flotation plants consist of complex interacting circuits where minerals are processed in different stages with recycling. Today, a common arrange are the RCS circuits, where a rougher circuit is combined with a cleaning circuit and a scavenger circuit. The global objectives of a flotation plant are to maximize the value metal recovery while the grade of the final concentrate is kept inside a narrow band. To achieve this, for any time variant feed attributes (flow rate, solid percent, grade, particle size distribution, pH, and chemicals), a capability of modifying the operation of each circuit, in order to achieve some local objectives, is demanded. To advance in this study, a family of simulators can be of great help. Recently, an algorithm to set the froth level profile in a rougher circuit, have been proposed. The simulator used was based on phenomenological models with parameters estimated from industrial data, collected under designed experiments. In this work, a simulator for the cleaning and scavenger circuits, including a regrinding stage is presented. This simulator is based on phenomenological models, with parameters estimated from industrial data. The simulators are used to provide insight on how the available resources in each circuit can be administrated, to obtain some local objectives which are harmonized in a global control strategy. Copyright© 2013 IFAC

Journal: IFAC Proceedings Volumes - Volume 46, Issue 16, 2013, Pages 110-115