| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 827669 | 1470273 | 2016 | 9 صفحه PDF | دانلود رایگان |

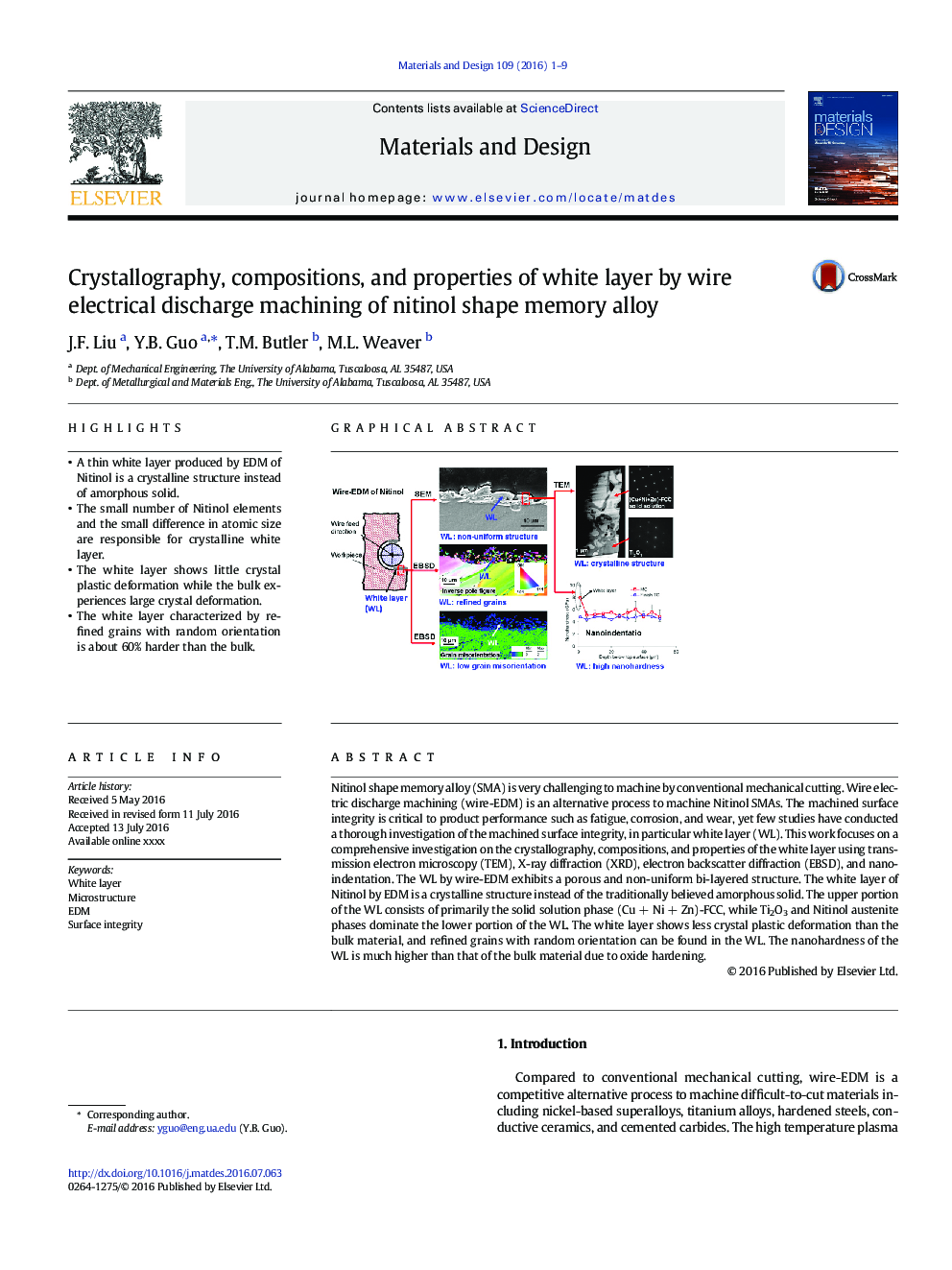

• A thin white layer produced by EDM of Nitinol is a crystalline structure instead of amorphous solid.

• The small number of Nitinol elements and the small difference in atomic size are responsible for crystalline white layer.

• The white layer shows little crystal plastic deformation while the bulk experiences large crystal deformation.

• The white layer characterized by refined grains with random orientation is about 60% harder than the bulk.

Nitinol shape memory alloy (SMA) is very challenging to machine by conventional mechanical cutting. Wire electric discharge machining (wire-EDM) is an alternative process to machine Nitinol SMAs. The machined surface integrity is critical to product performance such as fatigue, corrosion, and wear, yet few studies have conducted a thorough investigation of the machined surface integrity, in particular white layer (WL). This work focuses on a comprehensive investigation on the crystallography, compositions, and properties of the white layer using transmission electron microscopy (TEM), X-ray diffraction (XRD), electron backscatter diffraction (EBSD), and nanoindentation. The WL by wire-EDM exhibits a porous and non-uniform bi-layered structure. The white layer of Nitinol by EDM is a crystalline structure instead of the traditionally believed amorphous solid. The upper portion of the WL consists of primarily the solid solution phase (Cu + Ni + Zn)-FCC, while Ti2O3 and Nitinol austenite phases dominate the lower portion of the WL. The white layer shows less crystal plastic deformation than the bulk material, and refined grains with random orientation can be found in the WL. The nanohardness of the WL is much higher than that of the bulk material due to oxide hardening.

Figure optionsDownload as PowerPoint slide

Journal: Materials & Design - Volume 109, 5 November 2016, Pages 1–9