| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 827672 | 1470273 | 2016 | 10 صفحه PDF | دانلود رایگان |

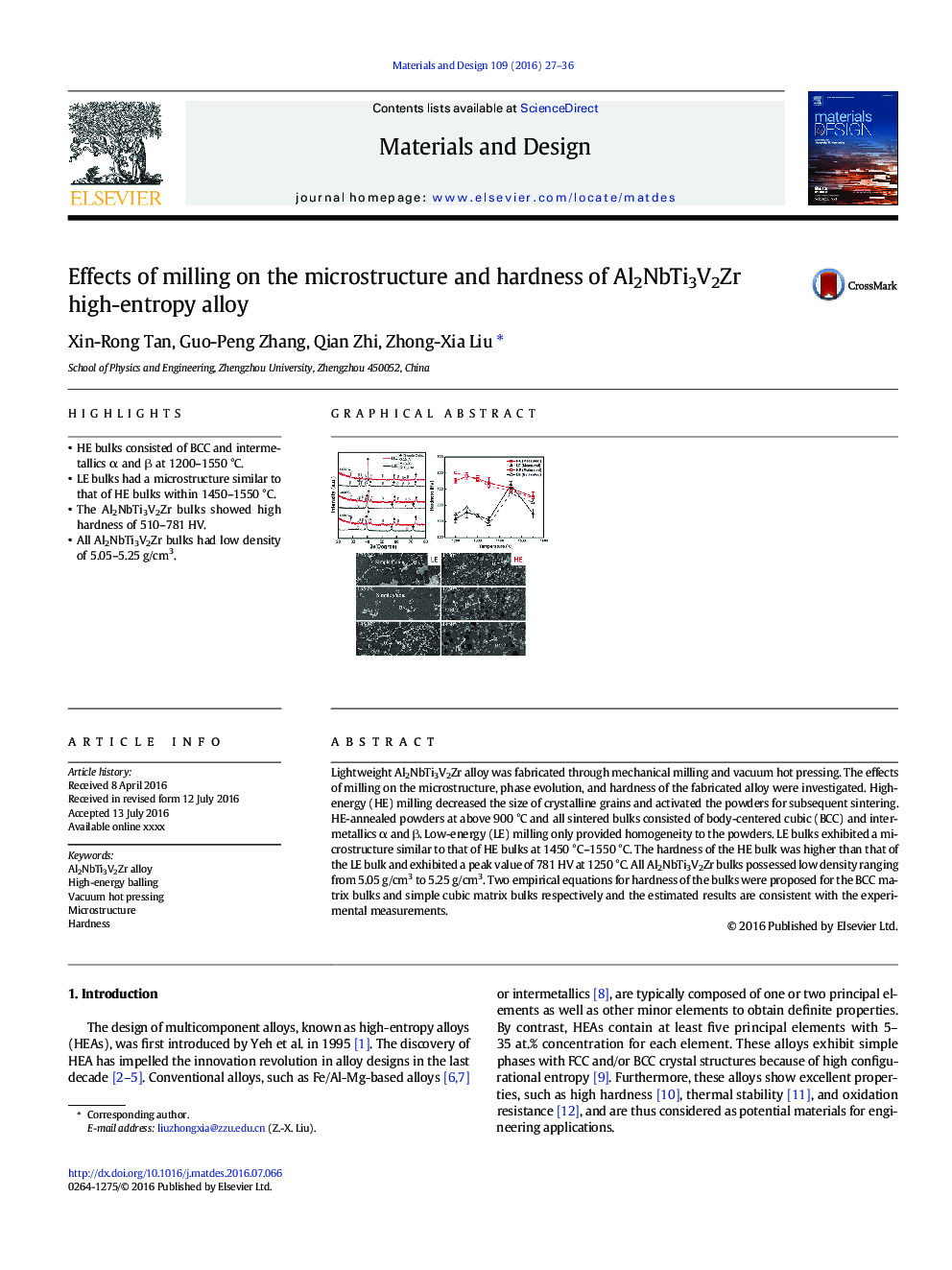

• HE bulks consisted of BCC and intermetallics α and β at 1200–1550 °C.

• LE bulks had a microstructure similar to that of HE bulks within 1450–1550 °C.

• The Al2NbTi3V2Zr bulks showed high hardness of 510–781 HV.

• All Al2NbTi3V2Zr bulks had low density of 5.05–5.25 g/cm3.

Lightweight Al2NbTi3V2Zr alloy was fabricated through mechanical milling and vacuum hot pressing. The effects of milling on the microstructure, phase evolution, and hardness of the fabricated alloy were investigated. High-energy (HE) milling decreased the size of crystalline grains and activated the powders for subsequent sintering. HE-annealed powders at above 900 °C and all sintered bulks consisted of body-centered cubic (BCC) and intermetallics α and β. Low-energy (LE) milling only provided homogeneity to the powders. LE bulks exhibited a microstructure similar to that of HE bulks at 1450 °C–1550 °C. The hardness of the HE bulk was higher than that of the LE bulk and exhibited a peak value of 781 HV at 1250 °C. All Al2NbTi3V2Zr bulks possessed low density ranging from 5.05 g/cm3 to 5.25 g/cm3. Two empirical equations for hardness of the bulks were proposed for the BCC matrix bulks and simple cubic matrix bulks respectively and the estimated results are consistent with the experimental measurements.

Figure optionsDownload as PowerPoint slide

Journal: Materials & Design - Volume 109, 5 November 2016, Pages 27–36