| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 827675 | 1470273 | 2016 | 11 صفحه PDF | دانلود رایگان |

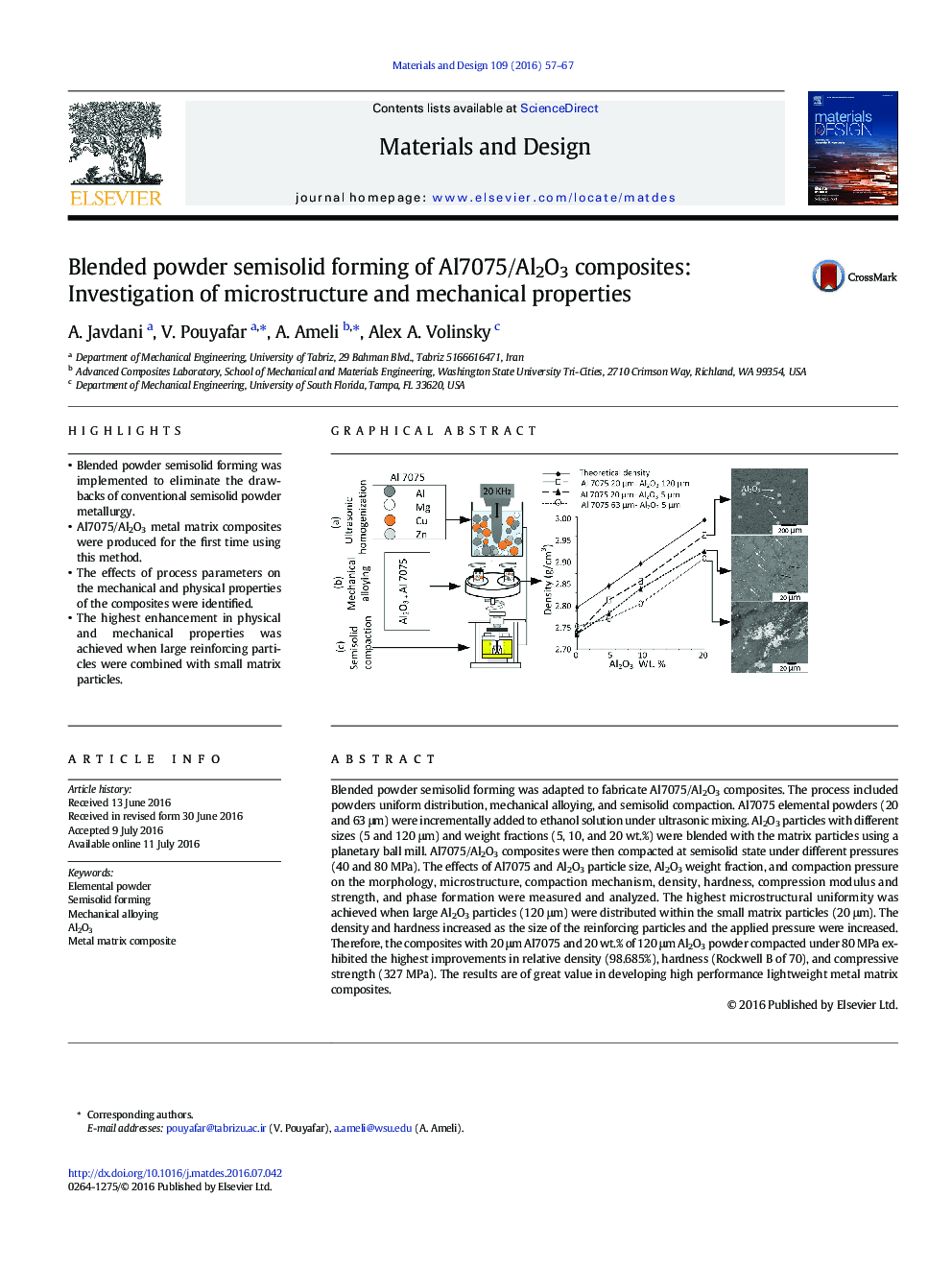

• Blended powder semisolid forming was implemented to eliminate the drawbacks of conventional semisolid powder metallurgy.

• Al7075/Al2O3 metal matrix composites were produced for the first time using this method.

• The effects of process parameters on the mechanical and physical properties of the composites were identified.

• The highest enhancement in physical and mechanical properties was achieved when large reinforcing particles were combined with small matrix particles.

Blended powder semisolid forming was adapted to fabricate Al7075/Al2O3 composites. The process included powders uniform distribution, mechanical alloying, and semisolid compaction. Al7075 elemental powders (20 and 63 μm) were incrementally added to ethanol solution under ultrasonic mixing. Al2O3 particles with different sizes (5 and 120 μm) and weight fractions (5, 10, and 20 wt.%) were blended with the matrix particles using a planetary ball mill. Al7075/Al2O3 composites were then compacted at semisolid state under different pressures (40 and 80 MPa). The effects of Al7075 and Al2O3 particle size, Al2O3 weight fraction, and compaction pressure on the morphology, microstructure, compaction mechanism, density, hardness, compression modulus and strength, and phase formation were measured and analyzed. The highest microstructural uniformity was achieved when large Al2O3 particles (120 μm) were distributed within the small matrix particles (20 μm). The density and hardness increased as the size of the reinforcing particles and the applied pressure were increased. Therefore, the composites with 20 μm Al7075 and 20 wt.% of 120 μm Al2O3 powder compacted under 80 MPa exhibited the highest improvements in relative density (98.685%), hardness (Rockwell B of 70), and compressive strength (327 MPa). The results are of great value in developing high performance lightweight metal matrix composites.

Figure optionsDownload as PowerPoint slide

Journal: Materials & Design - Volume 109, 5 November 2016, Pages 57–67