| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 827680 | 1470273 | 2016 | 11 صفحه PDF | دانلود رایگان |

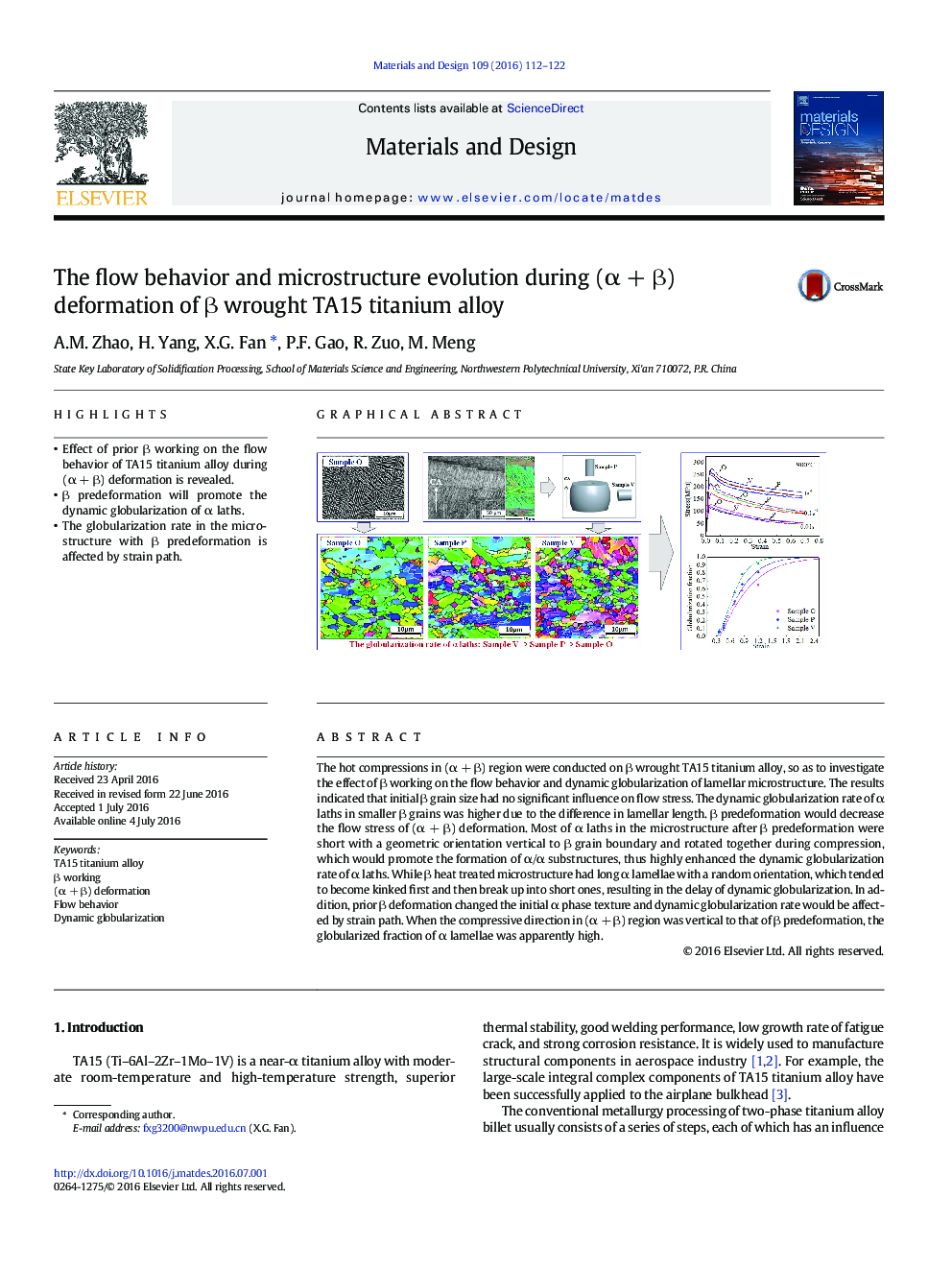

• Effect of prior β working on the flow behavior of TA15 titanium alloy during (α + β) deformation is revealed.

• β predeformation will promote the dynamic globularization of α laths.

• The globularization rate in the microstructure with β predeformation is affected by strain path.

The hot compressions in (α + β) region were conducted on β wrought TA15 titanium alloy, so as to investigate the effect of β working on the flow behavior and dynamic globularization of lamellar microstructure. The results indicated that initial β grain size had no significant influence on flow stress. The dynamic globularization rate of α laths in smaller β grains was higher due to the difference in lamellar length. β predeformation would decrease the flow stress of (α + β) deformation. Most of α laths in the microstructure after β predeformation were short with a geometric orientation vertical to β grain boundary and rotated together during compression, which would promote the formation of α/α substructures, thus highly enhanced the dynamic globularization rate of α laths. While β heat treated microstructure had long α lamellae with a random orientation, which tended to become kinked first and then break up into short ones, resulting in the delay of dynamic globularization. In addition, prior β deformation changed the initial α phase texture and dynamic globularization rate would be affected by strain path. When the compressive direction in (α + β) region was vertical to that of β predeformation, the globularized fraction of α lamellae was apparently high.

Figure optionsDownload as PowerPoint slide

Journal: Materials & Design - Volume 109, 5 November 2016, Pages 112–122