| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 827730 | 1470273 | 2016 | 10 صفحه PDF | دانلود رایگان |

• Incorporating fillers changes the tensile behaviour and hence the cutting force behaviour of an epoxy.

• Rigid silica results in higher cutting forces than soft rubber due to the stiffened and strengthened material properties.

• Fracture toughness plays a key role in surface finish, though its effect on the cutting forces is much less significant.

• Higher toughness to yield stress ratio and lower cut depth favour the controllability of the material removal process.

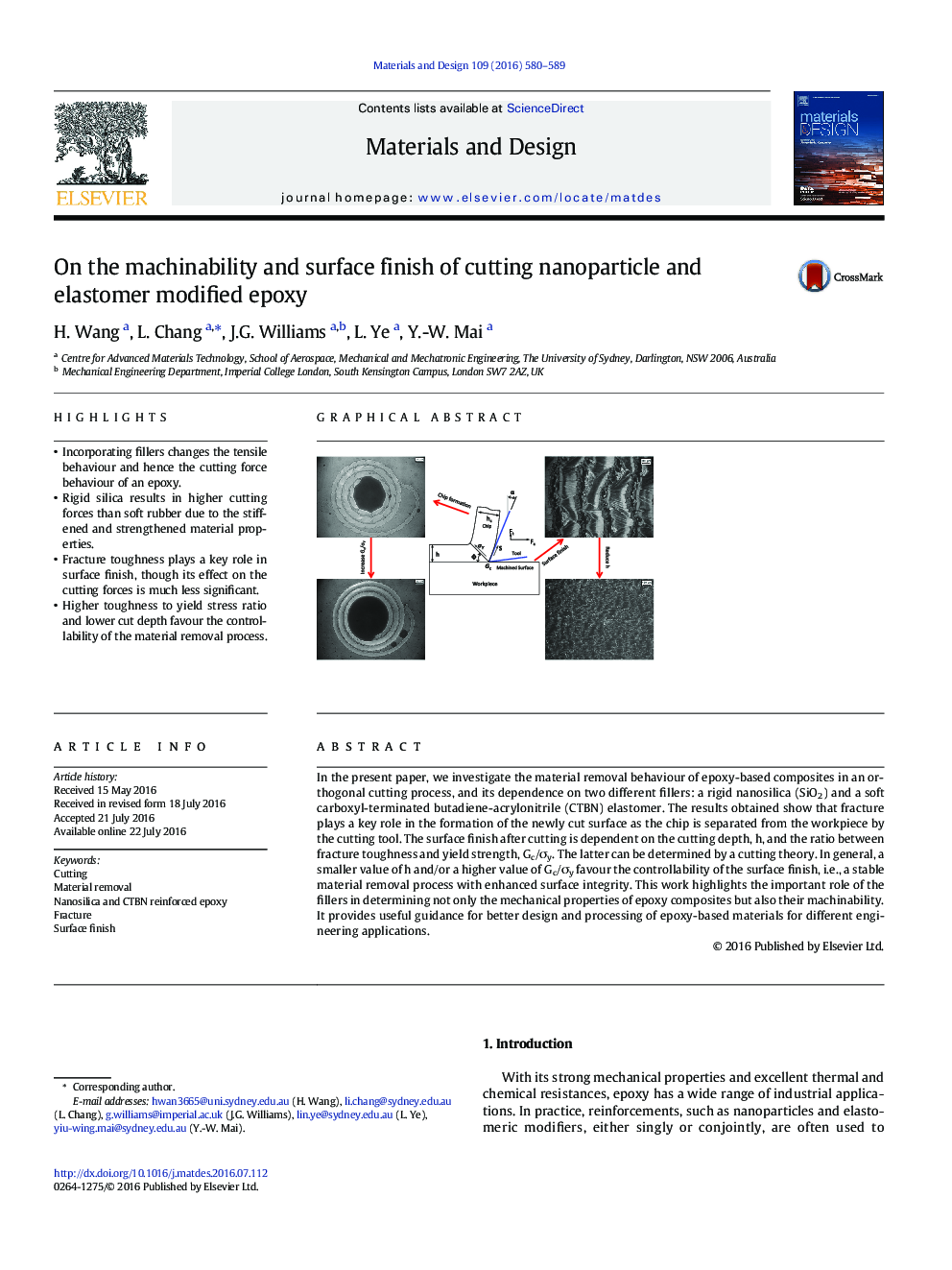

In the present paper, we investigate the material removal behaviour of epoxy-based composites in an orthogonal cutting process, and its dependence on two different fillers: a rigid nanosilica (SiO2) and a soft carboxyl-terminated butadiene-acrylonitrile (CTBN) elastomer. The results obtained show that fracture plays a key role in the formation of the newly cut surface as the chip is separated from the workpiece by the cutting tool. The surface finish after cutting is dependent on the cutting depth, h, and the ratio between fracture toughness and yield strength, Gc/σy. The latter can be determined by a cutting theory. In general, a smaller value of h and/or a higher value of Gc/σy favour the controllability of the surface finish, i.e., a stable material removal process with enhanced surface integrity. This work highlights the important role of the fillers in determining not only the mechanical properties of epoxy composites but also their machinability. It provides useful guidance for better design and processing of epoxy-based materials for different engineering applications.

Figure optionsDownload as PowerPoint slide

Journal: Materials & Design - Volume 109, 5 November 2016, Pages 580–589