| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 1603719 | 1515987 | 2012 | 5 صفحه PDF | دانلود رایگان |

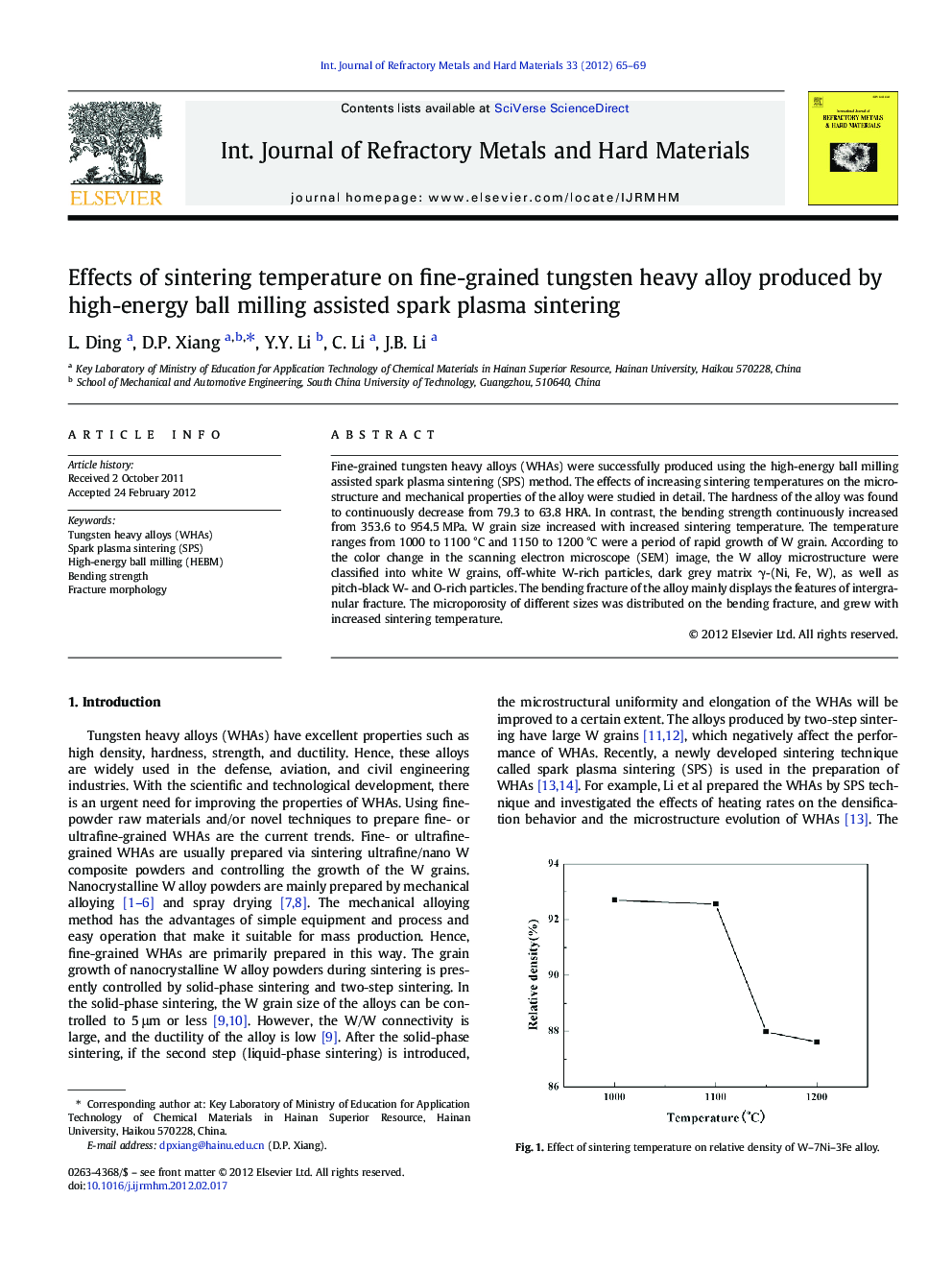

Fine-grained tungsten heavy alloys (WHAs) were successfully produced using the high-energy ball milling assisted spark plasma sintering (SPS) method. The effects of increasing sintering temperatures on the microstructure and mechanical properties of the alloy were studied in detail. The hardness of the alloy was found to continuously decrease from 79.3 to 63.8 HRA. In contrast, the bending strength continuously increased from 353.6 to 954.5 MPa. W grain size increased with increased sintering temperature. The temperature ranges from 1000 to 1100 °C and 1150 to 1200 °C were a period of rapid growth of W grain. According to the color change in the scanning electron microscope (SEM) image, the W alloy microstructure were classified into white W grains, off-white W-rich particles, dark grey matrix γ-(Ni, Fe, W), as well as pitch-black W- and O-rich particles. The bending fracture of the alloy mainly displays the features of intergranular fracture. The microporosity of different sizes was distributed on the bending fracture, and grew with increased sintering temperature.

► Fine-grained WHAs were fabricated by HEBM assisted SPS technology.

► The HEBM-SPS method improves the bending strength of the WHAs.

► The microstructure of fine-grained WHAs consists of four different phases.

► The intergranular fracture is dominant for most fine-grained WHAs.

Journal: International Journal of Refractory Metals and Hard Materials - Volume 33, July 2012, Pages 65–69