| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 1679215 | 1010201 | 2007 | 30 صفحه PDF | دانلود رایگان |

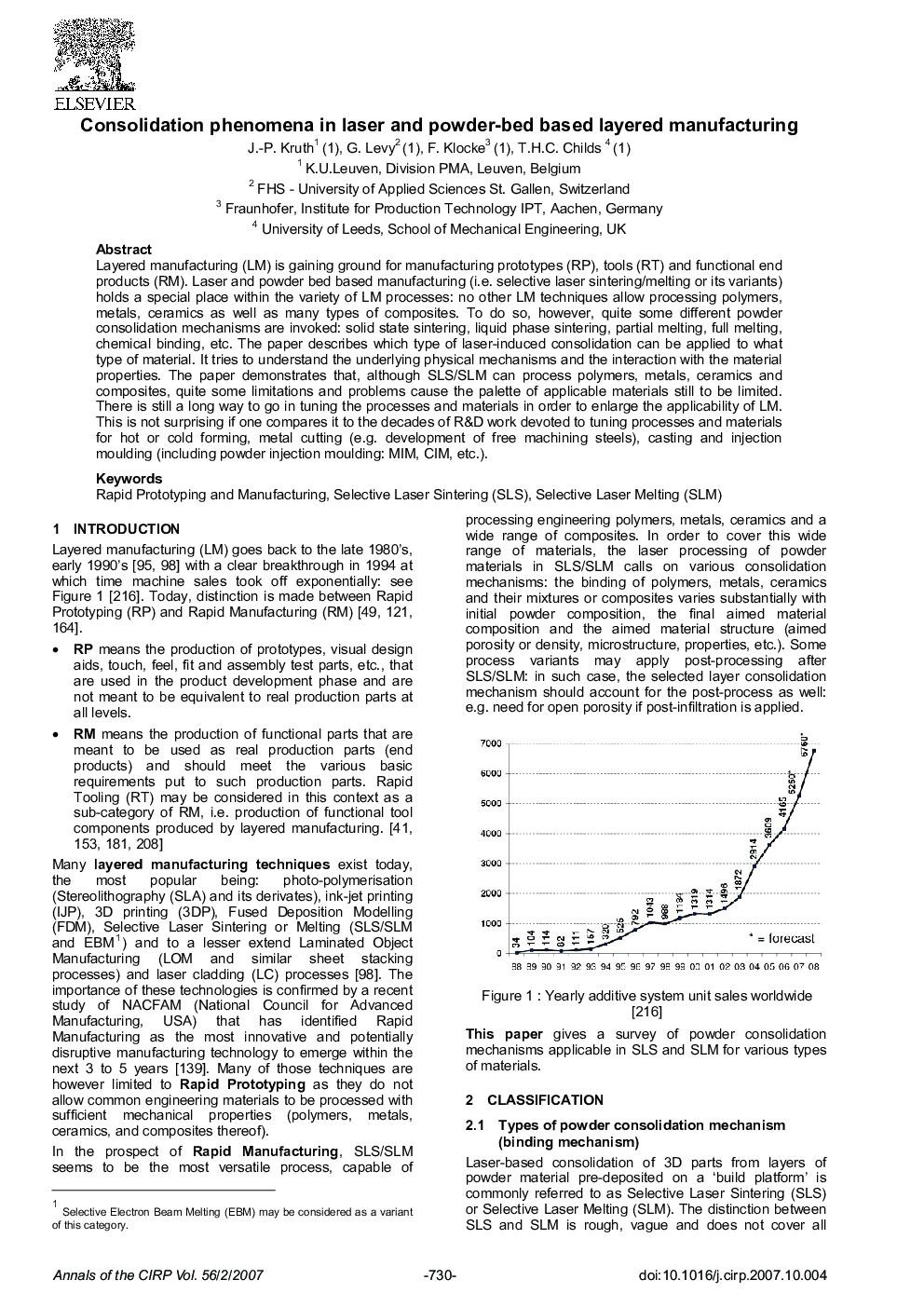

Layered manufacturing (LM) is gaining ground for manufacturing prototypes (RP), tools (RT) and functional end products (RM). Laser and powder bed based manufacturing (i.e. selective laser sintering/melting or its variants) holds a special place within the variety of LM processes: no other LM techniques allow processing polymers, metals, ceramics as well as many types of composites. To do so, however, quite some different powder consolidation mechanisms are invoked: solid state sintering, liquid phase sintering, partial melting, full melting, chemical binding, etc. The paper describes which type of laser-induced consolidation can be applied to what type of material. It tries to understand the underlying physical mechanisms and the interaction with the material properties. The paper demonstrates that, although SLS/SLM can process polymers, metals, ceramics and composites, quite some limitations and problems cause the palette of applicable materials still to be limited. There is still a long way to go in tuning the processes and materials in order to enlarge the applicability of LM. This is not surprising if one compares it to the decades of R&D work devoted to tuning processes and materials for hot or cold forming, metal cutting (e.g. development of free machining steels), casting and injection moulding (including powder injection moulding: MIM, CIM, etc.).

Journal: CIRP Annals - Manufacturing Technology - Volume 56, Issue 2, 2007, Pages 730-759