| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 255832 | 503533 | 2016 | 14 صفحه PDF | دانلود رایگان |

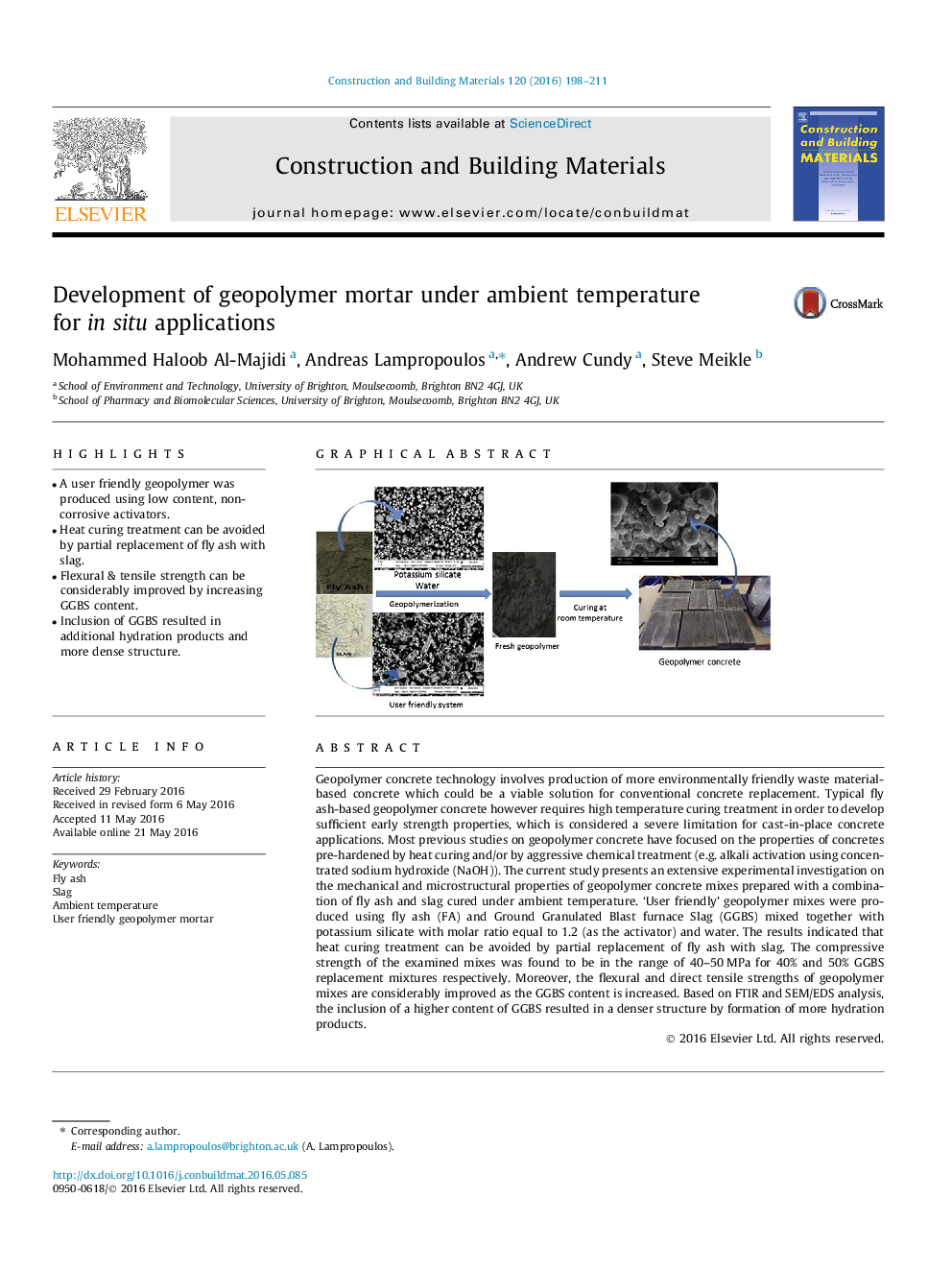

• A user friendly geopolymer was produced using low content, non-corrosive activators.

• Heat curing treatment can be avoided by partial replacement of fly ash with slag.

• Flexural & tensile strength can be considerably improved by increasing GGBS content.

• Inclusion of GGBS resulted in additional hydration products and more dense structure.

Geopolymer concrete technology involves production of more environmentally friendly waste material-based concrete which could be a viable solution for conventional concrete replacement. Typical fly ash-based geopolymer concrete however requires high temperature curing treatment in order to develop sufficient early strength properties, which is considered a severe limitation for cast-in-place concrete applications. Most previous studies on geopolymer concrete have focused on the properties of concretes pre-hardened by heat curing and/or by aggressive chemical treatment (e.g. alkali activation using concentrated sodium hydroxide (NaOH)). The current study presents an extensive experimental investigation on the mechanical and microstructural properties of geopolymer concrete mixes prepared with a combination of fly ash and slag cured under ambient temperature. ‘User friendly’ geopolymer mixes were produced using fly ash (FA) and Ground Granulated Blast furnace Slag (GGBS) mixed together with potassium silicate with molar ratio equal to 1.2 (as the activator) and water. The results indicated that heat curing treatment can be avoided by partial replacement of fly ash with slag. The compressive strength of the examined mixes was found to be in the range of 40–50 MPa for 40% and 50% GGBS replacement mixtures respectively. Moreover, the flexural and direct tensile strengths of geopolymer mixes are considerably improved as the GGBS content is increased. Based on FTIR and SEM/EDS analysis, the inclusion of a higher content of GGBS resulted in a denser structure by formation of more hydration products.

Figure optionsDownload as PowerPoint slide

Journal: Construction and Building Materials - Volume 120, 1 September 2016, Pages 198–211