| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6473774 | 1424964 | 2017 | 7 صفحه PDF | دانلود رایگان |

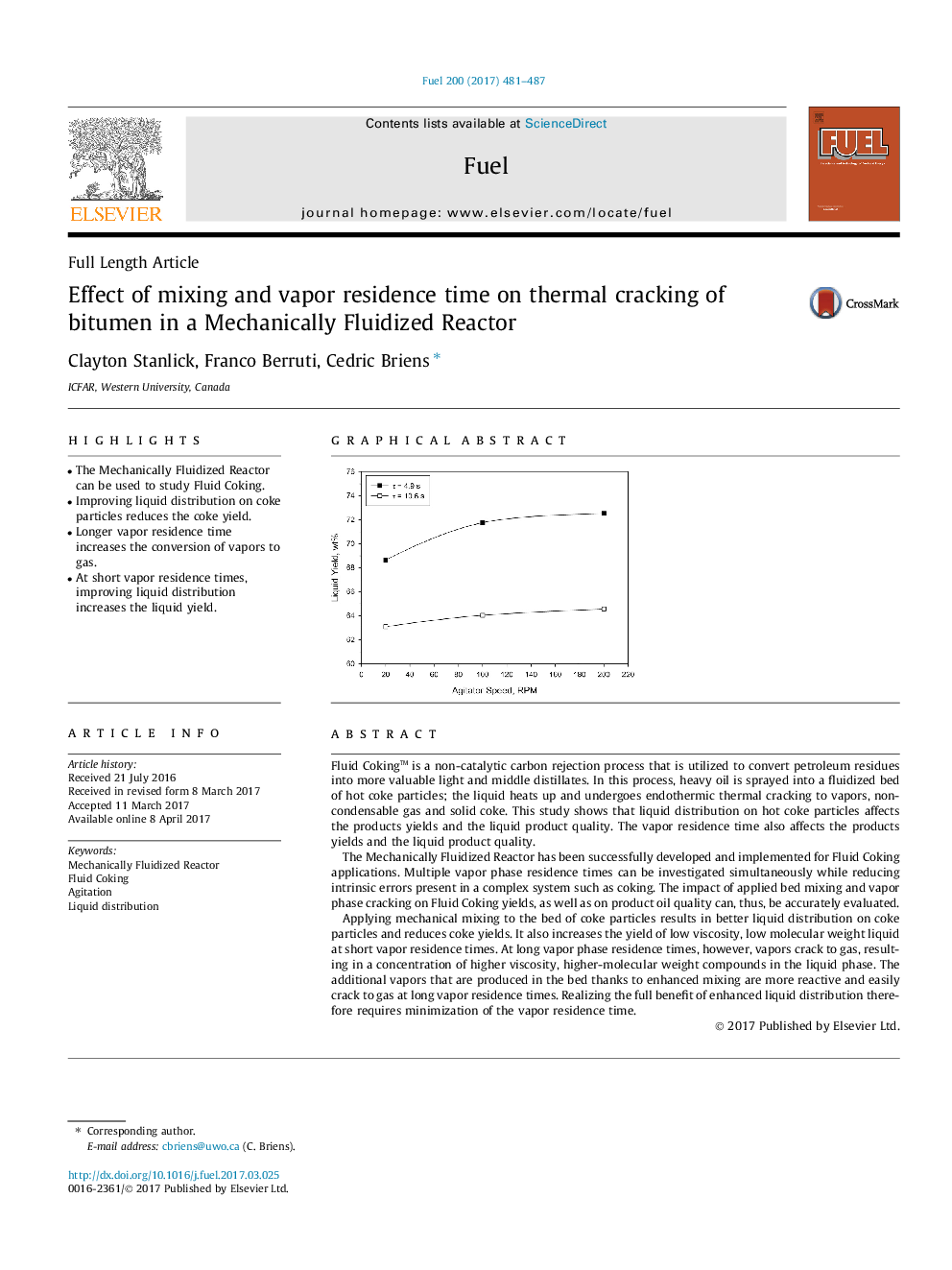

- The Mechanically Fluidized Reactor can be used to study Fluid Coking.

- Improving liquid distribution on coke particles reduces the coke yield.

- Longer vapor residence time increases the conversion of vapors to gas.

- At short vapor residence times, improving liquid distribution increases the liquid yield.

Fluid Coking⢠is a non-catalytic carbon rejection process that is utilized to convert petroleum residues into more valuable light and middle distillates. In this process, heavy oil is sprayed into a fluidized bed of hot coke particles; the liquid heats up and undergoes endothermic thermal cracking to vapors, non-condensable gas and solid coke. This study shows that liquid distribution on hot coke particles affects the products yields and the liquid product quality. The vapor residence time also affects the products yields and the liquid product quality.The Mechanically Fluidized Reactor has been successfully developed and implemented for Fluid Coking applications. Multiple vapor phase residence times can be investigated simultaneously while reducing intrinsic errors present in a complex system such as coking. The impact of applied bed mixing and vapor phase cracking on Fluid Coking yields, as well as on product oil quality can, thus, be accurately evaluated.Applying mechanical mixing to the bed of coke particles results in better liquid distribution on coke particles and reduces coke yields. It also increases the yield of low viscosity, low molecular weight liquid at short vapor residence times. At long vapor phase residence times, however, vapors crack to gas, resulting in a concentration of higher viscosity, higher-molecular weight compounds in the liquid phase. The additional vapors that are produced in the bed thanks to enhanced mixing are more reactive and easily crack to gas at long vapor residence times. Realizing the full benefit of enhanced liquid distribution therefore requires minimization of the vapor residence time.

66

Journal: Fuel - Volume 200, 15 July 2017, Pages 481-487