| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6474360 | 1424961 | 2017 | 8 صفحه PDF | دانلود رایگان |

- Synthetic bio-oil produced by mixing model compounds featuring light fractions.

- Design of experiments techniques applied to represent wide range of compositions.

- Iron oxide with additives reduced by vaporized synthetic bio-oils.

- Oxidation of metallic iron releases high purity hydrogen.

- Effect of composition of liquid, reduction temperature and number of cycles.

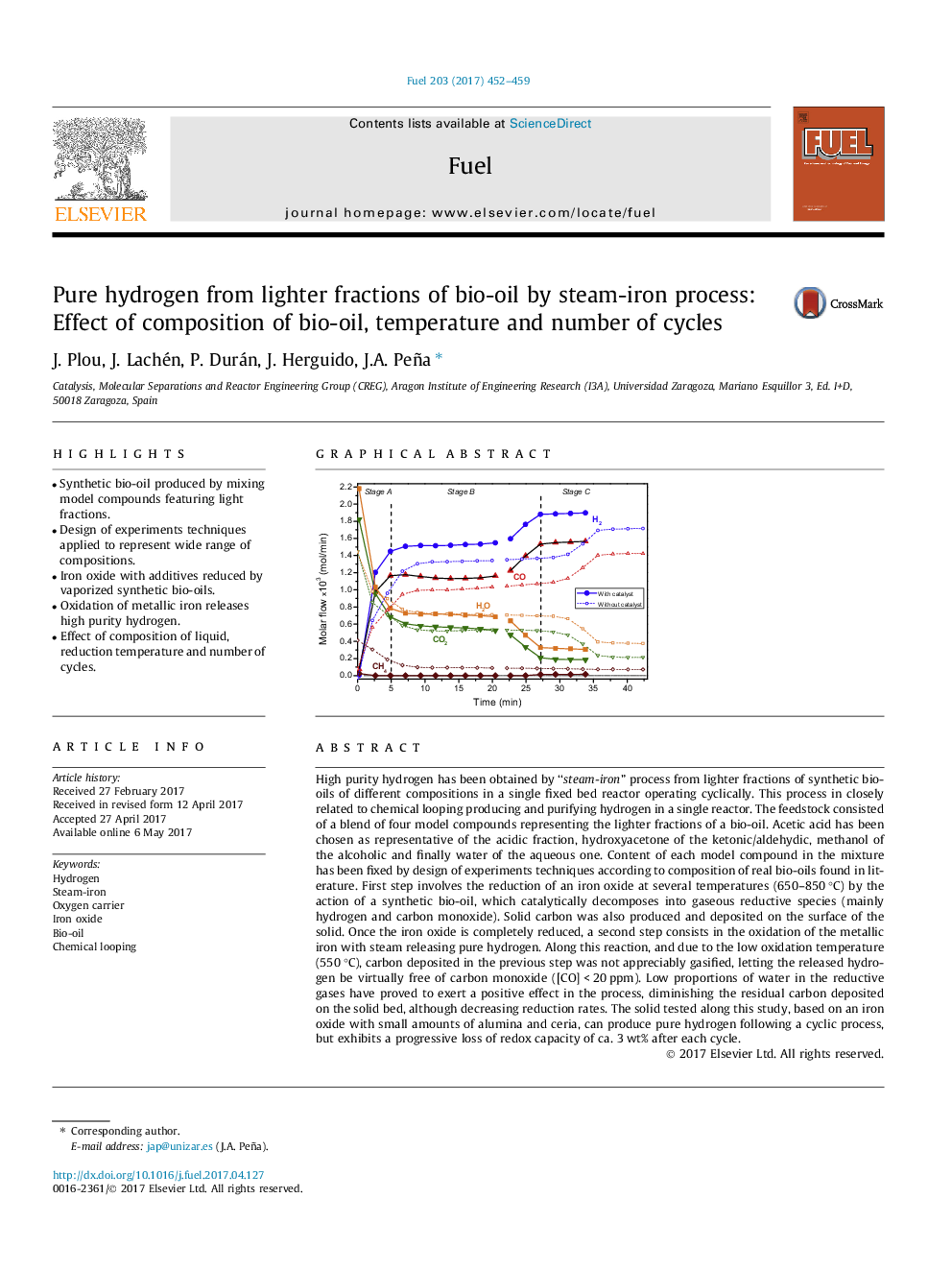

High purity hydrogen has been obtained by “steam-iron” process from lighter fractions of synthetic bio-oils of different compositions in a single fixed bed reactor operating cyclically. This process in closely related to chemical looping producing and purifying hydrogen in a single reactor. The feedstock consisted of a blend of four model compounds representing the lighter fractions of a bio-oil. Acetic acid has been chosen as representative of the acidic fraction, hydroxyacetone of the ketonic/aldehydic, methanol of the alcoholic and finally water of the aqueous one. Content of each model compound in the mixture has been fixed by design of experiments techniques according to composition of real bio-oils found in literature. First step involves the reduction of an iron oxide at several temperatures (650-850 °C) by the action of a synthetic bio-oil, which catalytically decomposes into gaseous reductive species (mainly hydrogen and carbon monoxide). Solid carbon was also produced and deposited on the surface of the solid. Once the iron oxide is completely reduced, a second step consists in the oxidation of the metallic iron with steam releasing pure hydrogen. Along this reaction, and due to the low oxidation temperature (550 °C), carbon deposited in the previous step was not appreciably gasified, letting the released hydrogen be virtually free of carbon monoxide ([CO] < 20 ppm). Low proportions of water in the reductive gases have proved to exert a positive effect in the process, diminishing the residual carbon deposited on the solid bed, although decreasing reduction rates. The solid tested along this study, based on an iron oxide with small amounts of alumina and ceria, can produce pure hydrogen following a cyclic process, but exhibits a progressive loss of redox capacity of ca. 3 wt% after each cycle.

182

Journal: Fuel - Volume 203, 1 September 2017, Pages 452-459