| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6476010 | 1424978 | 2016 | 14 صفحه PDF | دانلود رایگان |

- Bitumen recovery using solvent and water assisted electrical heating is demonstrated.

- The process has potential to entirely eliminate steam generation plant.

- Surface facilities for this process are significantly smaller than SAGD.

- Water-oil-ratios for this process can be 3-10 times lower than that of SAGD.

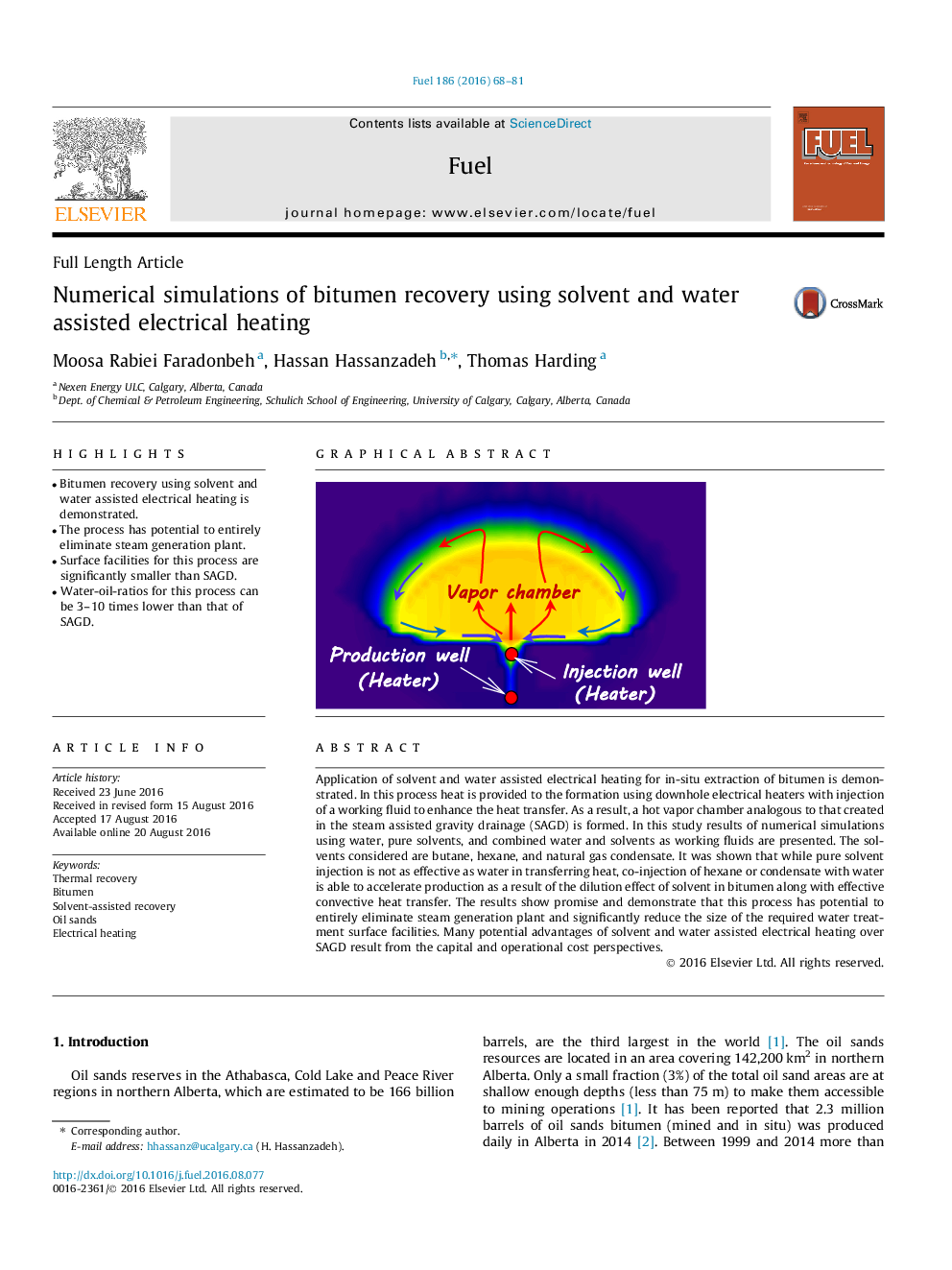

Application of solvent and water assisted electrical heating for in-situ extraction of bitumen is demonstrated. In this process heat is provided to the formation using downhole electrical heaters with injection of a working fluid to enhance the heat transfer. As a result, a hot vapor chamber analogous to that created in the steam assisted gravity drainage (SAGD) is formed. In this study results of numerical simulations using water, pure solvents, and combined water and solvents as working fluids are presented. The solvents considered are butane, hexane, and natural gas condensate. It was shown that while pure solvent injection is not as effective as water in transferring heat, co-injection of hexane or condensate with water is able to accelerate production as a result of the dilution effect of solvent in bitumen along with effective convective heat transfer. The results show promise and demonstrate that this process has potential to entirely eliminate steam generation plant and significantly reduce the size of the required water treatment surface facilities. Many potential advantages of solvent and water assisted electrical heating over SAGD result from the capital and operational cost perspectives.

Graphical Abstract171

Journal: Fuel - Volume 186, 15 December 2016, Pages 68-81