| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 1292919 | 1497956 | 2015 | 12 صفحه PDF | دانلود رایگان |

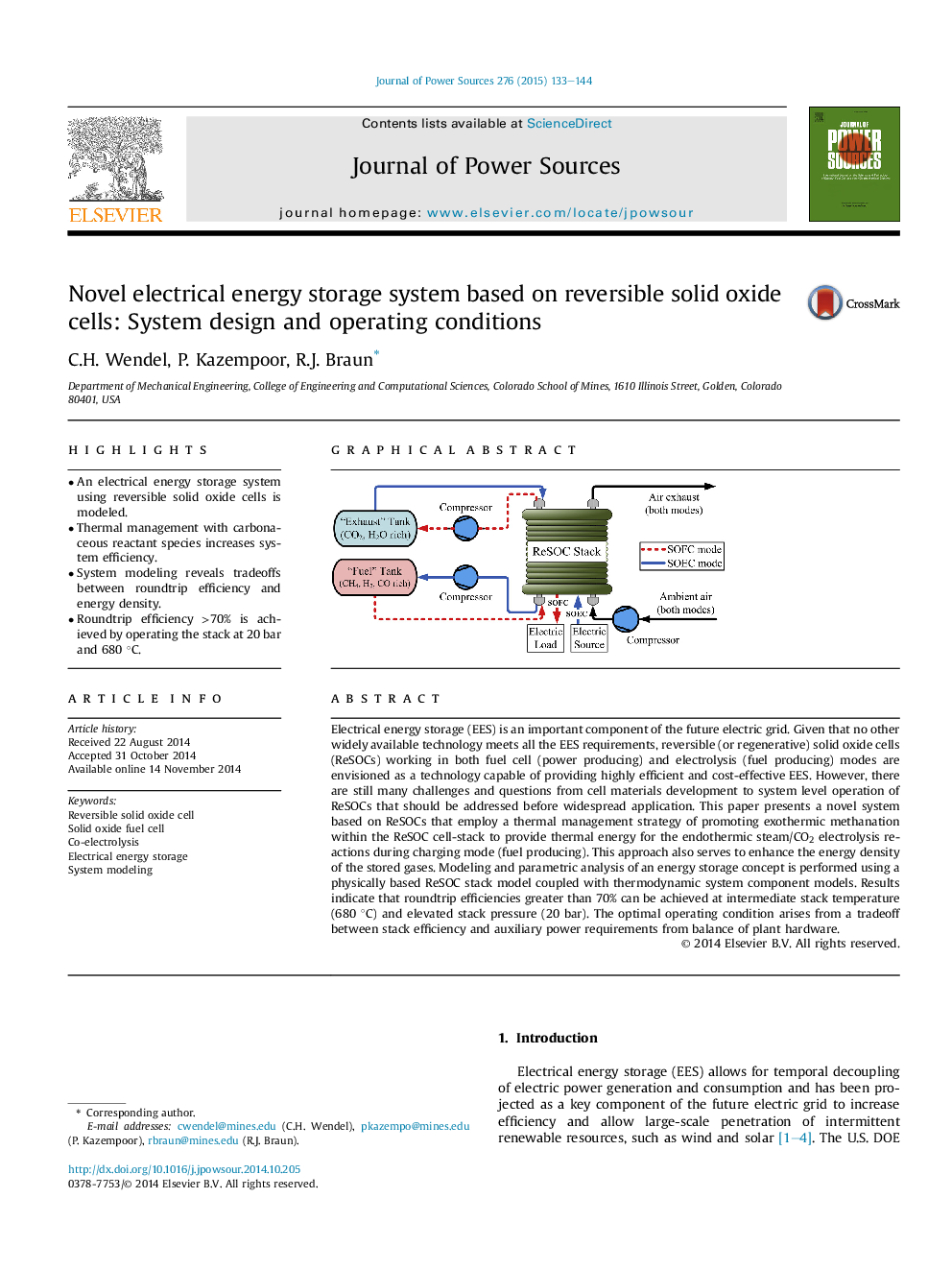

• An electrical energy storage system using reversible solid oxide cells is modeled.

• Thermal management with carbonaceous reactant species increases system efficiency.

• System modeling reveals tradeoffs between roundtrip efficiency and energy density.

• Roundtrip efficiency >70% is achieved by operating the stack at 20 bar and 680 °C.

Electrical energy storage (EES) is an important component of the future electric grid. Given that no other widely available technology meets all the EES requirements, reversible (or regenerative) solid oxide cells (ReSOCs) working in both fuel cell (power producing) and electrolysis (fuel producing) modes are envisioned as a technology capable of providing highly efficient and cost-effective EES. However, there are still many challenges and questions from cell materials development to system level operation of ReSOCs that should be addressed before widespread application. This paper presents a novel system based on ReSOCs that employ a thermal management strategy of promoting exothermic methanation within the ReSOC cell-stack to provide thermal energy for the endothermic steam/CO2 electrolysis reactions during charging mode (fuel producing). This approach also serves to enhance the energy density of the stored gases. Modeling and parametric analysis of an energy storage concept is performed using a physically based ReSOC stack model coupled with thermodynamic system component models. Results indicate that roundtrip efficiencies greater than 70% can be achieved at intermediate stack temperature (680 °C) and elevated stack pressure (20 bar). The optimal operating condition arises from a tradeoff between stack efficiency and auxiliary power requirements from balance of plant hardware.

Figure optionsDownload as PowerPoint slide

Journal: Journal of Power Sources - Volume 276, 15 February 2015, Pages 133–144