| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 146191 | 456363 | 2015 | 11 صفحه PDF | دانلود رایگان |

• Simulation studies of dual-layer and dual-brick Fe/Cu-SCR catalysts.

• Identified optimal catalyst loading for dual-layer and dual-brick configurations.

• Dual-brick is found to be slightly superior to dual-layer in terms of NOx conversion.

• Washcoat diffusion effect is more significant in dual-layer than in dual-brick catalyst.

Cu-based SCR catalysts exhibit higher activity at lower temperatures (<350 °C) while Fe-based catalysts are more active at higher temperatures under “standard” SCR condition (NH3 + NO + O2). The combination of Fe- and Cu-based SCR catalysts provides a viable solution to expand the temperature window of high NOx conversion. A simulation study of combined Fe/Cu SCR catalyst is carried to: (i) compare the performance of the dual-layer and dual-brick catalysts for different proportions of Fe- and Cu-zeolite catalysts, (ii) identify the optimal catalyst (washcoat) loadings of individual components in each configuration, and (iii) identify the superior design. The simulations show that there is an optimal fraction of Fe and Cu loadings in the combined systems. The optimal fraction of the Fe-zeolite washcoat in the dual-layer catalyst is lower than that in the dual-brick design. It is shown that the dual-brick configuration gives a higher overall NO conversion performance for most conditions. The main cause for the inferior performance of the dual-layer catalyst is the diffusional limitation that lowers the NO conversion at intermediate temperatures. In this temperature range the Cu-SCR catalyst is more active than the Fe-SCR catalyst, so diffusional limitations are more severe for the Cu catalyst. As a result, the Fe-SCR top layer in the dual-layer architecture creates an additional barrier, lowering the apparent activity of the Cu-SCR. Because the activity of the combined system is largely contributed by Cu-SCR at intermediate temperatures, the NO conversion of the combined system is lowered. This performance decrease due to the addition of the Fe-SCR layer overshadows its benefits at higher temperatures. In the dual-brick configuration, this adverse effect due to diffusional resistance is not as detrimental.

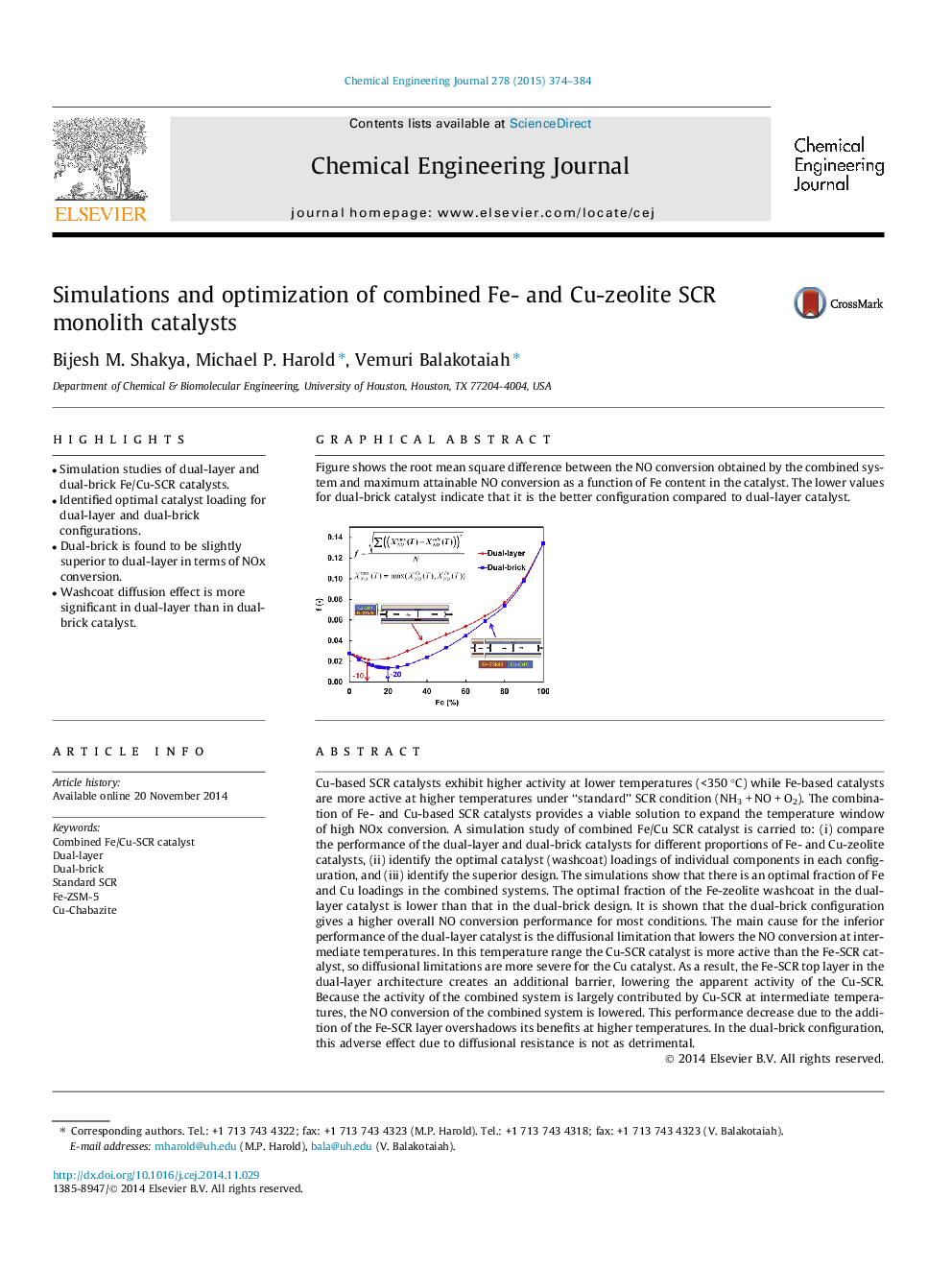

Figure shows the root mean square difference between the NO conversion obtained by the combined system and maximum attainable NO conversion as a function of Fe content in the catalyst. The lower values for dual-brick catalyst indicate that it is the better configuration compared to dual-layer catalyst.Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 278, 15 October 2015, Pages 374–384