| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 146196 | 456363 | 2015 | 17 صفحه PDF | دانلود رایگان |

• Mathematical model has been developed for nitric acid manufacture.

• Kinetics of oxidation and decomposition of nitrous acid included in the model.

• The role of enriched oxygen on the oxidation of NO and HNO2.

• A novel method has been proposed for the liquid phase oxidation of HNO2.

• The novel method stops NO desorption and saves volume for gas phase oxidation.

Absorption column occupies a dominant place in the manufacturing of nitric acid. A mathematical model has been developed for the absorption of NOx gases using air and enriched oxygen in packed columns. For the first time, this paper considers the kinetics of nitrous acid decomposition and oxidation in the liquid phase. Till date, the published literature considers the instantaneous decomposition of nitrous acid in the liquid phase. The same case has also been considered in this paper as the base case. In addition, three more cases have been considered: (1) decomposition and oxidation kinetics of nitrous acid with a typical concentration of oxygen which is usually employed in nitric acid plants (2) complete decomposition and oxidation with enriched oxygen (3) complete conversion of nitrous to nitric acid by liquid phase nitrous acid oxidation. Enriched oxygen results in substantial reduction in column volume and/or the operating pressure. The enriched oxygen enhances the rate of nitrous acid oxidation (to nitric acid) and hence the nitrous acid available for decomposition reduces throughout the column. This implies that lesser quantity of nitric oxide gets desorbed to the gas phase. This feature has crucial implication because the need for gas phase oxidation of NO reduces and hence the absorption column becomes compact due to reduction in oxidation volume. Thus, the enriched oxygen plays a significant role in process intensification and equipment miniaturization. Additionally, the liquid phase oxidation of nitrous acid carried out in a suitable oxidizer was found to give substantial additional reduction in the column volume.For packed column absorber, the effects of design parameters viz. column diameter, heights of packed and empty sections, and operating parameters such as pressure and temperature have been examined.

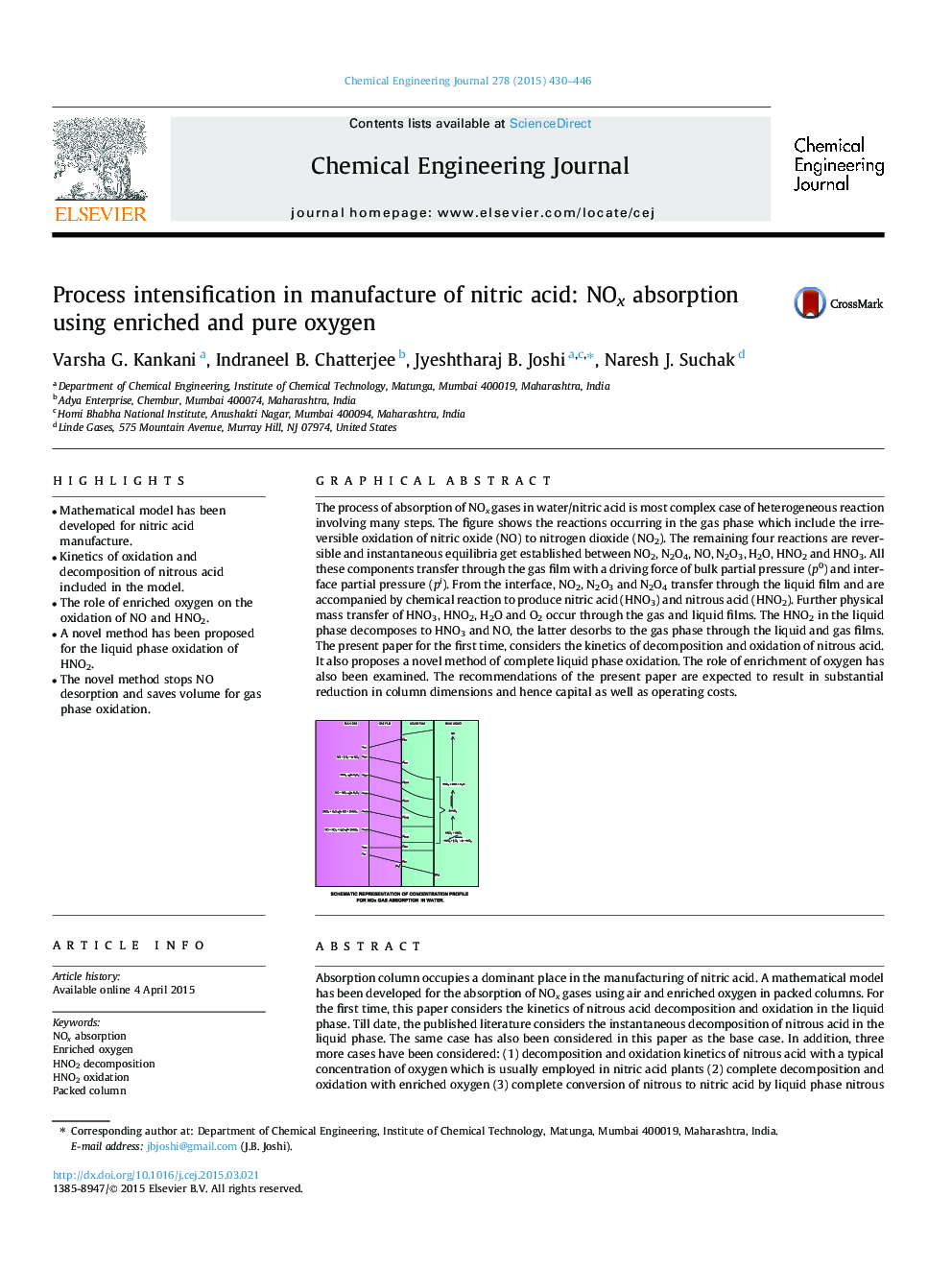

The process of absorption of NOx gases in water/nitric acid is most complex case of heterogeneous reaction involving many steps. The figure shows the reactions occurring in the gas phase which include the irreversible oxidation of nitric oxide (NO) to nitrogen dioxide (NO2). The remaining four reactions are reversible and instantaneous equilibria get established between NO2, N2O4, NO, N2O3, H2O, HNO2 and HNO3. All these components transfer through the gas film with a driving force of bulk partial pressure (p0) and interface partial pressure (pi). From the interface, NO2, N2O3 and N2O4 transfer through the liquid film and are accompanied by chemical reaction to produce nitric acid (HNO3) and nitrous acid (HNO2). Further physical mass transfer of HNO3, HNO2, H2O and O2 occur through the gas and liquid films. The HNO2 in the liquid phase decomposes to HNO3 and NO, the latter desorbs to the gas phase through the liquid and gas films. The present paper for the first time, considers the kinetics of decomposition and oxidation of nitrous acid. It also proposes a novel method of complete liquid phase oxidation. The role of enrichment of oxygen has also been examined. The recommendations of the present paper are expected to result in substantial reduction in column dimensions and hence capital as well as operating costs.Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 278, 15 October 2015, Pages 430–446