| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 146812 | 456378 | 2015 | 6 صفحه PDF | دانلود رایگان |

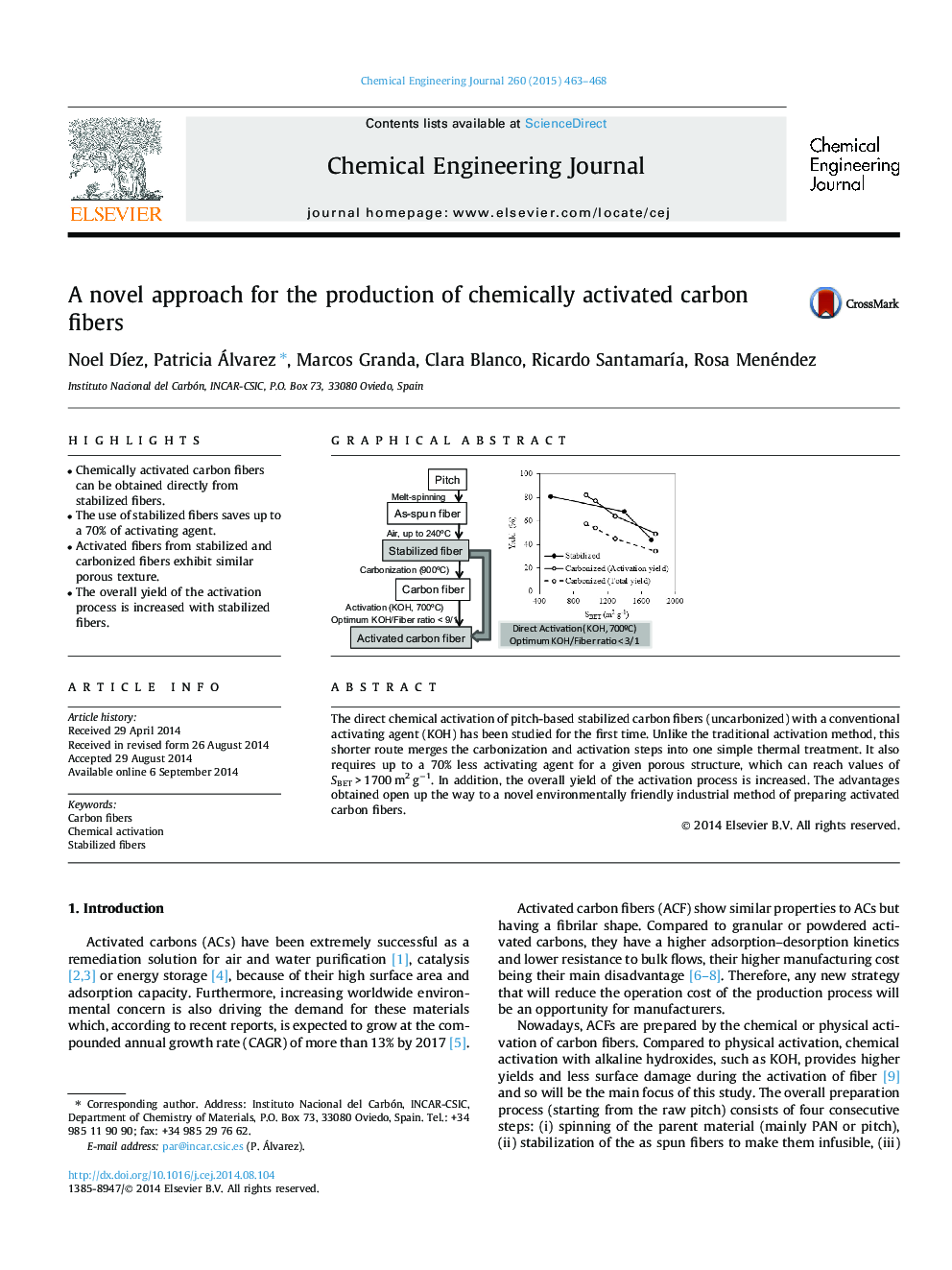

• Chemically activated carbon fibers can be obtained directly from stabilized fibers.

• The use of stabilized fibers saves up to a 70% of activating agent.

• Activated fibers from stabilized and carbonized fibers exhibit similar porous texture.

• The overall yield of the activation process is increased with stabilized fibers.

The direct chemical activation of pitch-based stabilized carbon fibers (uncarbonized) with a conventional activating agent (KOH) has been studied for the first time. Unlike the traditional activation method, this shorter route merges the carbonization and activation steps into one simple thermal treatment. It also requires up to a 70% less activating agent for a given porous structure, which can reach values of SBET > 1700 m2 g−1. In addition, the overall yield of the activation process is increased. The advantages obtained open up the way to a novel environmentally friendly industrial method of preparing activated carbon fibers.

Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 260, 15 January 2015, Pages 463–468