| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 147963 | 456402 | 2014 | 11 صفحه PDF | دانلود رایگان |

• A high voltage plate added in the chamber to induce auxiliary electric field (AEF).

• FEM calculations helped to examine the influence of flow and electric fields.

• AEF enhanced the collection efficiency but did not affect particle size distribution.

• AEF damaged smoothness of the particles when high voltage was applied to the plate.

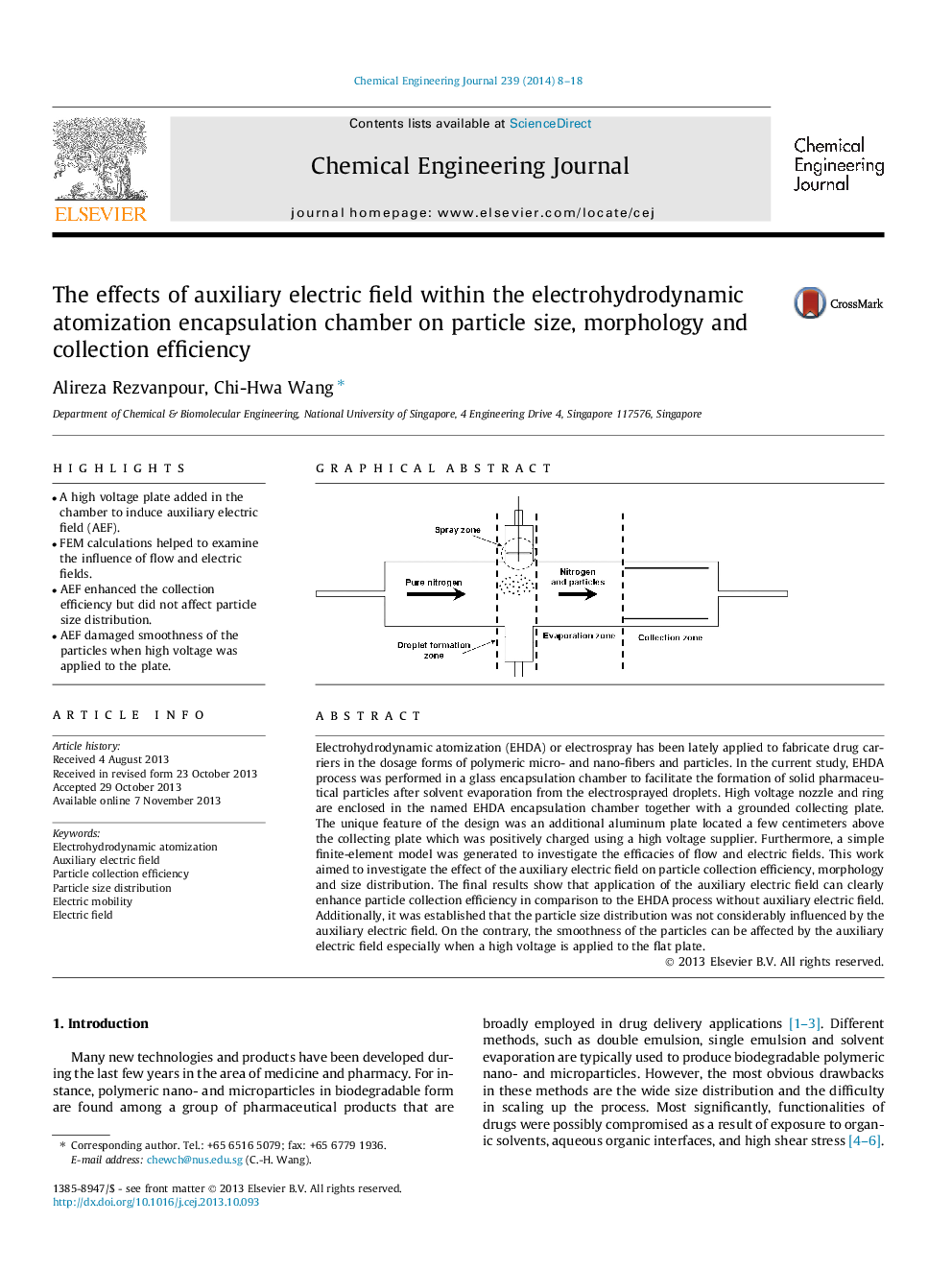

Electrohydrodynamic atomization (EHDA) or electrospray has been lately applied to fabricate drug carriers in the dosage forms of polymeric micro- and nano-fibers and particles. In the current study, EHDA process was performed in a glass encapsulation chamber to facilitate the formation of solid pharmaceutical particles after solvent evaporation from the electrosprayed droplets. High voltage nozzle and ring are enclosed in the named EHDA encapsulation chamber together with a grounded collecting plate. The unique feature of the design was an additional aluminum plate located a few centimeters above the collecting plate which was positively charged using a high voltage supplier. Furthermore, a simple finite-element model was generated to investigate the efficacies of flow and electric fields. This work aimed to investigate the effect of the auxiliary electric field on particle collection efficiency, morphology and size distribution. The final results show that application of the auxiliary electric field can clearly enhance particle collection efficiency in comparison to the EHDA process without auxiliary electric field. Additionally, it was established that the particle size distribution was not considerably influenced by the auxiliary electric field. On the contrary, the smoothness of the particles can be affected by the auxiliary electric field especially when a high voltage is applied to the flat plate.

Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 239, 1 March 2014, Pages 8–18