| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 148043 | 456404 | 2014 | 9 صفحه PDF | دانلود رایگان |

• Tubular reactor for formaldehyde oxidation into formic acid was modeled.

• Process flowsheet with two reactors for formaldehyde oxidation is favorable.

• Pilot plant for formic acid production is designed and constructed.

• Formic acid yield of 87–88% based on formaldehyde is obtained.

• Methanol consumption is 0.75–0.80 kg per 1 kg of 85% formic acid.

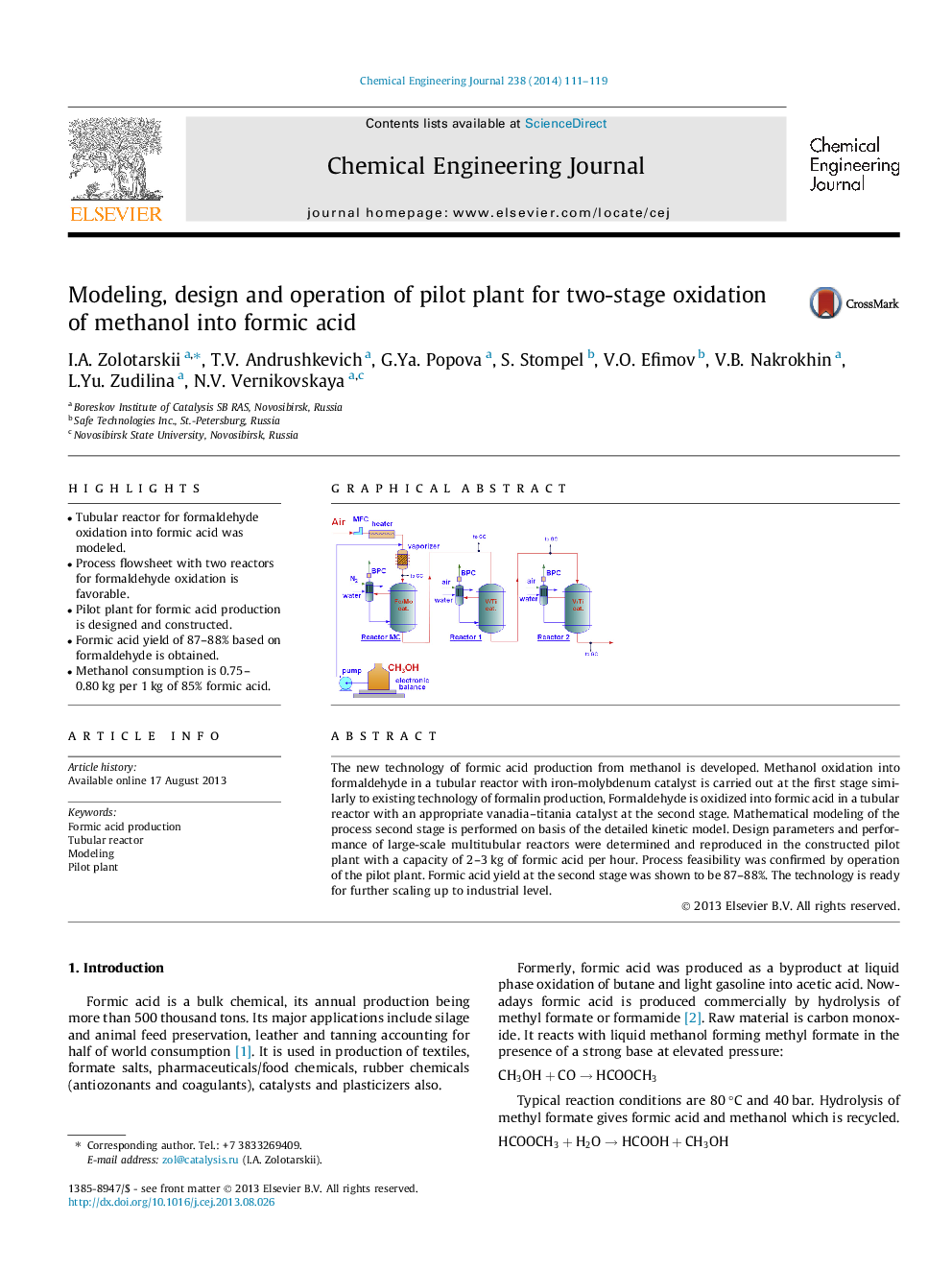

The new technology of formic acid production from methanol is developed. Methanol oxidation into formaldehyde in a tubular reactor with iron-molybdenum catalyst is carried out at the first stage similarly to existing technology of formalin production, Formaldehyde is oxidized into formic acid in a tubular reactor with an appropriate vanadia–titania catalyst at the second stage. Mathematical modeling of the process second stage is performed on basis of the detailed kinetic model. Design parameters and performance of large-scale multitubular reactors were determined and reproduced in the constructed pilot plant with a capacity of 2–3 kg of formic acid per hour. Process feasibility was confirmed by operation of the pilot plant. Formic acid yield at the second stage was shown to be 87–88%. The technology is ready for further scaling up to industrial level.

Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 238, 15 February 2014, Pages 111–119