| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 4991953 | 1457115 | 2017 | 9 صفحه PDF | دانلود رایگان |

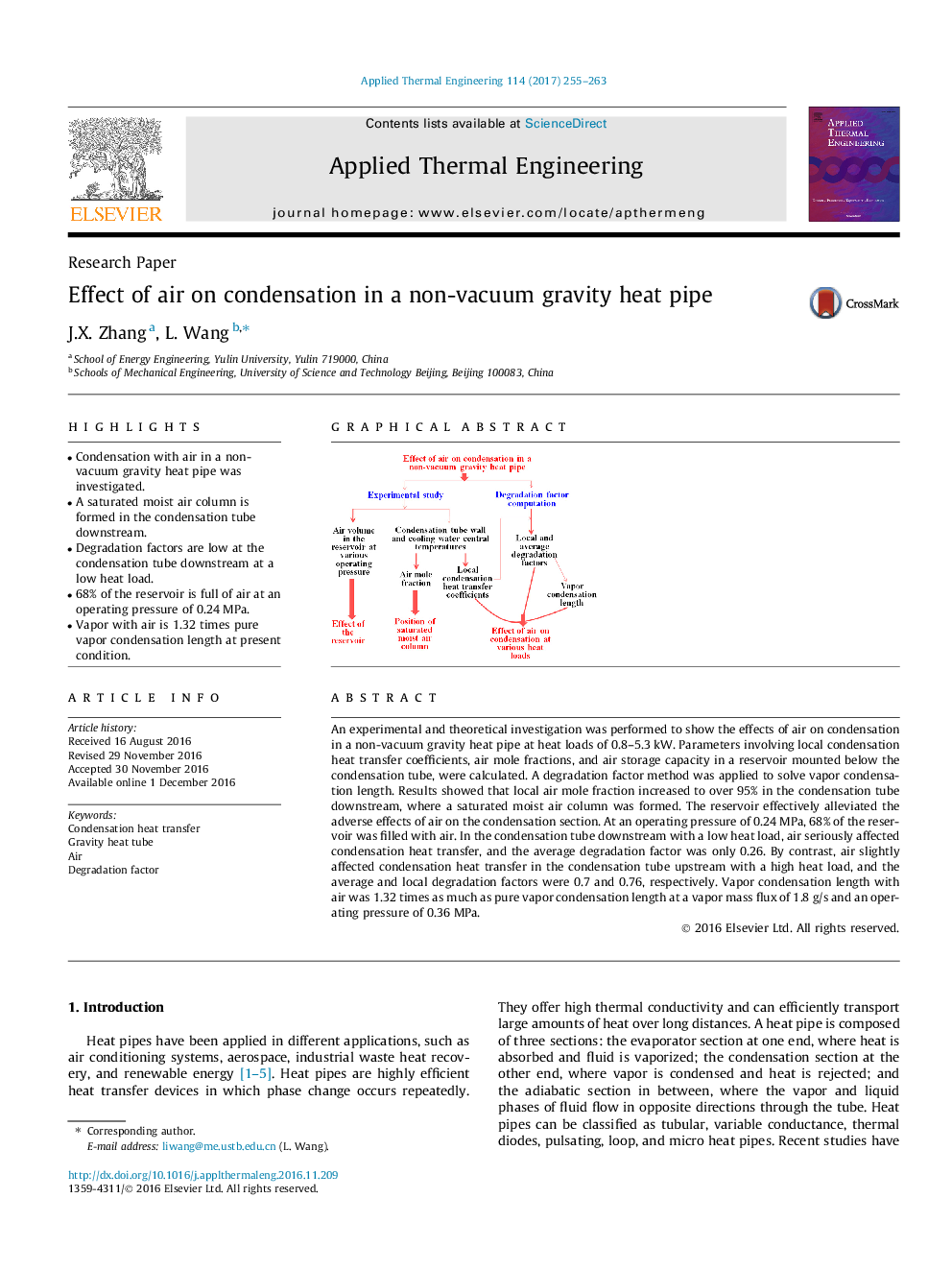

- Condensation with air in a non-vacuum gravity heat pipe was investigated.

- A saturated moist air column is formed in the condensation tube downstream.

- Degradation factors are low at the condensation tube downstream at a low heat load.

- 68% of the reservoir is full of air at an operating pressure of 0.24Â MPa.

- Vapor with air is 1.32 times pure vapor condensation length at present condition.

An experimental and theoretical investigation was performed to show the effects of air on condensation in a non-vacuum gravity heat pipe at heat loads of 0.8-5.3Â kW. Parameters involving local condensation heat transfer coefficients, air mole fractions, and air storage capacity in a reservoir mounted below the condensation tube, were calculated. A degradation factor method was applied to solve vapor condensation length. Results showed that local air mole fraction increased to over 95% in the condensation tube downstream, where a saturated moist air column was formed. The reservoir effectively alleviated the adverse effects of air on the condensation section. At an operating pressure of 0.24Â MPa, 68% of the reservoir was filled with air. In the condensation tube downstream with a low heat load, air seriously affected condensation heat transfer, and the average degradation factor was only 0.26. By contrast, air slightly affected condensation heat transfer in the condensation tube upstream with a high heat load, and the average and local degradation factors were 0.7 and 0.76, respectively. Vapor condensation length with air was 1.32 times as much as pure vapor condensation length at a vapor mass flux of 1.8Â g/s and an operating pressure of 0.36Â MPa.

80

Journal: Applied Thermal Engineering - Volume 114, 5 March 2017, Pages 255-263