| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6429721 | 1634775 | 2013 | 11 صفحه PDF | دانلود رایگان |

- Approach: First of its kind study of simultaneous experimental measurements of wear and frictional under high, seismic velocity (1 m/s).

- Observed: Wear-rates depend on BOTH normal stress and slip velocity, in contradiction to classical (Archard, 1953).

- Observed: Experimental power-density is the best predictor of friction coefficient of carbonate faults.

- The first wear-map and friction-map of rock faults are presented.

- Wear and friction variations indicate a brittle-ductile transition due to frictions heating.

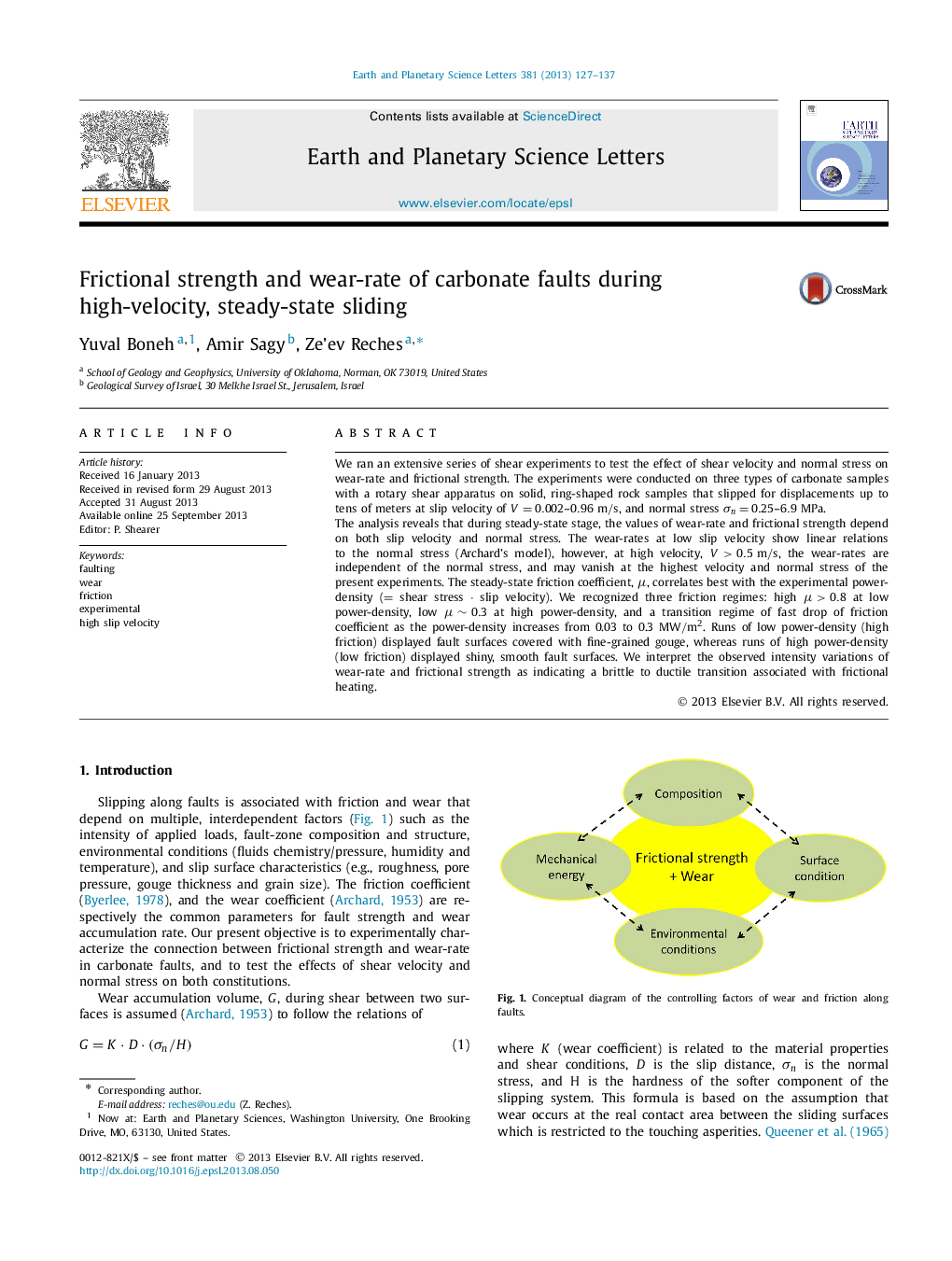

We ran an extensive series of shear experiments to test the effect of shear velocity and normal stress on wear-rate and frictional strength. The experiments were conducted on three types of carbonate samples with a rotary shear apparatus on solid, ring-shaped rock samples that slipped for displacements up to tens of meters at slip velocity of V=0.002-0.96 m/s, and normal stress Ïn=0.25-6.9 MPa.The analysis reveals that during steady-state stage, the values of wear-rate and frictional strength depend on both slip velocity and normal stress. The wear-rates at low slip velocity show linear relations to the normal stress (Archardʼs model), however, at high velocity, V>0.5 m/s, the wear-rates are independent of the normal stress, and may vanish at the highest velocity and normal stress of the present experiments. The steady-state friction coefficient, μ, correlates best with the experimental power-density (= shear stress â slip velocity). We recognized three friction regimes: high μ>0.8 at low power-density, low μâ¼0.3 at high power-density, and a transition regime of fast drop of friction coefficient as the power-density increases from 0.03 to 0.3 MW/m2. Runs of low power-density (high friction) displayed fault surfaces covered with fine-grained gouge, whereas runs of high power-density (low friction) displayed shiny, smooth fault surfaces. We interpret the observed intensity variations of wear-rate and frictional strength as indicating a brittle to ductile transition associated with frictional heating.

Journal: Earth and Planetary Science Letters - Volume 381, 1 November 2013, Pages 127-137