| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 645436 | 1457139 | 2015 | 10 صفحه PDF | دانلود رایگان |

• Total Site Profile (TSP) directed approach to process modifications.

• Increased temperature driving force to reduce capital costs.

• Manipulate TSP shape using keep hot stream hot and keep cold stream cold principles.

• Target process modifications at selected TSP segments to improve Heat Integration.

• New heuristics to prioritise the changes in TSP segments and process streams.

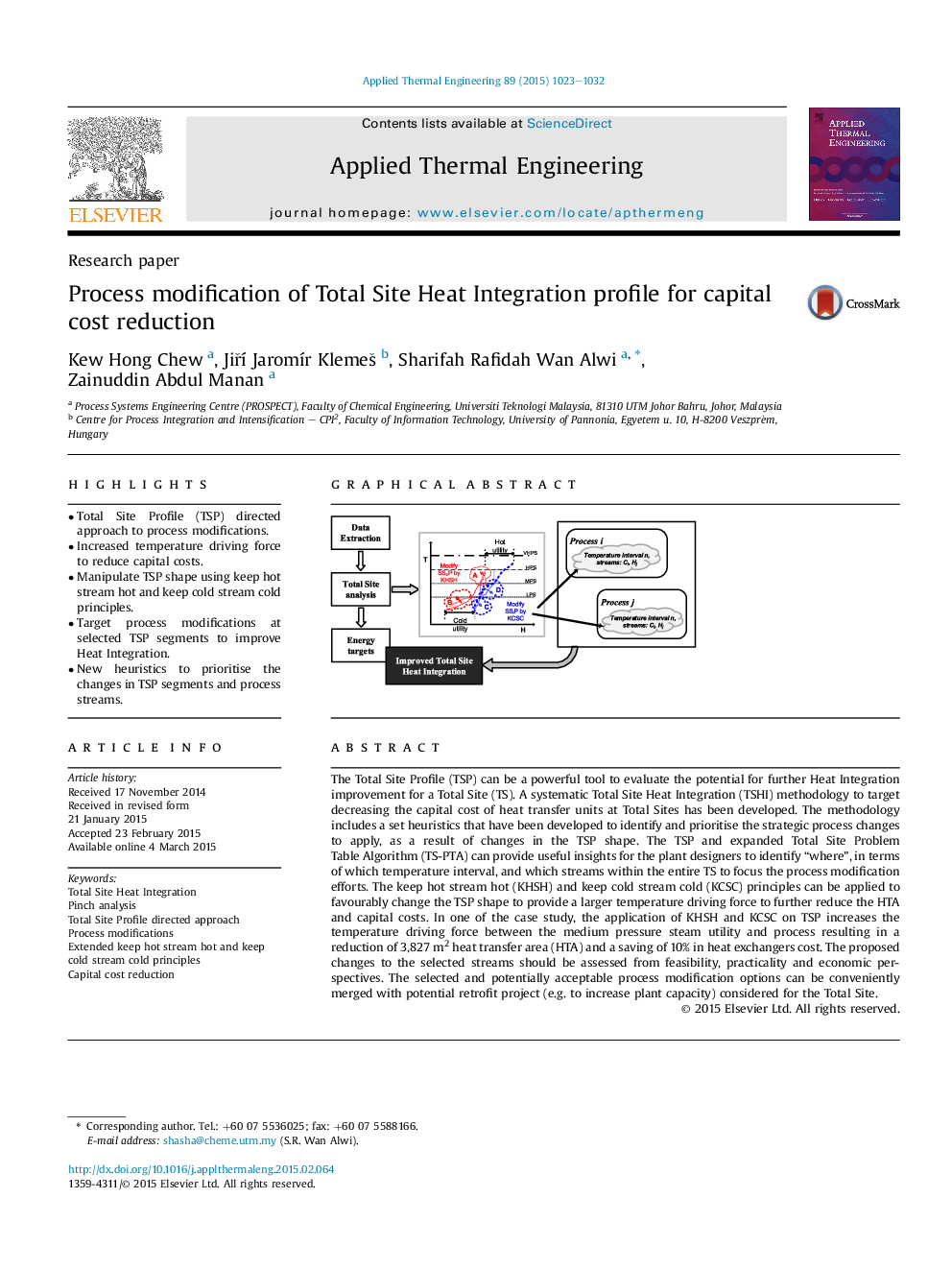

The Total Site Profile (TSP) can be a powerful tool to evaluate the potential for further Heat Integration improvement for a Total Site (TS). A systematic Total Site Heat Integration (TSHI) methodology to target decreasing the capital cost of heat transfer units at Total Sites has been developed. The methodology includes a set heuristics that have been developed to identify and prioritise the strategic process changes to apply, as a result of changes in the TSP shape. The TSP and expanded Total Site Problem Table Algorithm (TS-PTA) can provide useful insights for the plant designers to identify “where”, in terms of which temperature interval, and which streams within the entire TS to focus the process modification efforts. The keep hot stream hot (KHSH) and keep cold stream cold (KCSC) principles can be applied to favourably change the TSP shape to provide a larger temperature driving force to further reduce the HTA and capital costs. In one of the case study, the application of KHSH and KCSC on TSP increases the temperature driving force between the medium pressure steam utility and process resulting in a reduction of 3,827 m2 heat transfer area (HTA) and a saving of 10% in heat exchangers cost. The proposed changes to the selected streams should be assessed from feasibility, practicality and economic perspectives. The selected and potentially acceptable process modification options can be conveniently merged with potential retrofit project (e.g. to increase plant capacity) considered for the Total Site.

Figure optionsDownload as PowerPoint slide

Journal: Applied Thermal Engineering - Volume 89, 5 October 2015, Pages 1023–1032