| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6465579 | 1422952 | 2017 | 17 صفحه PDF | دانلود رایگان |

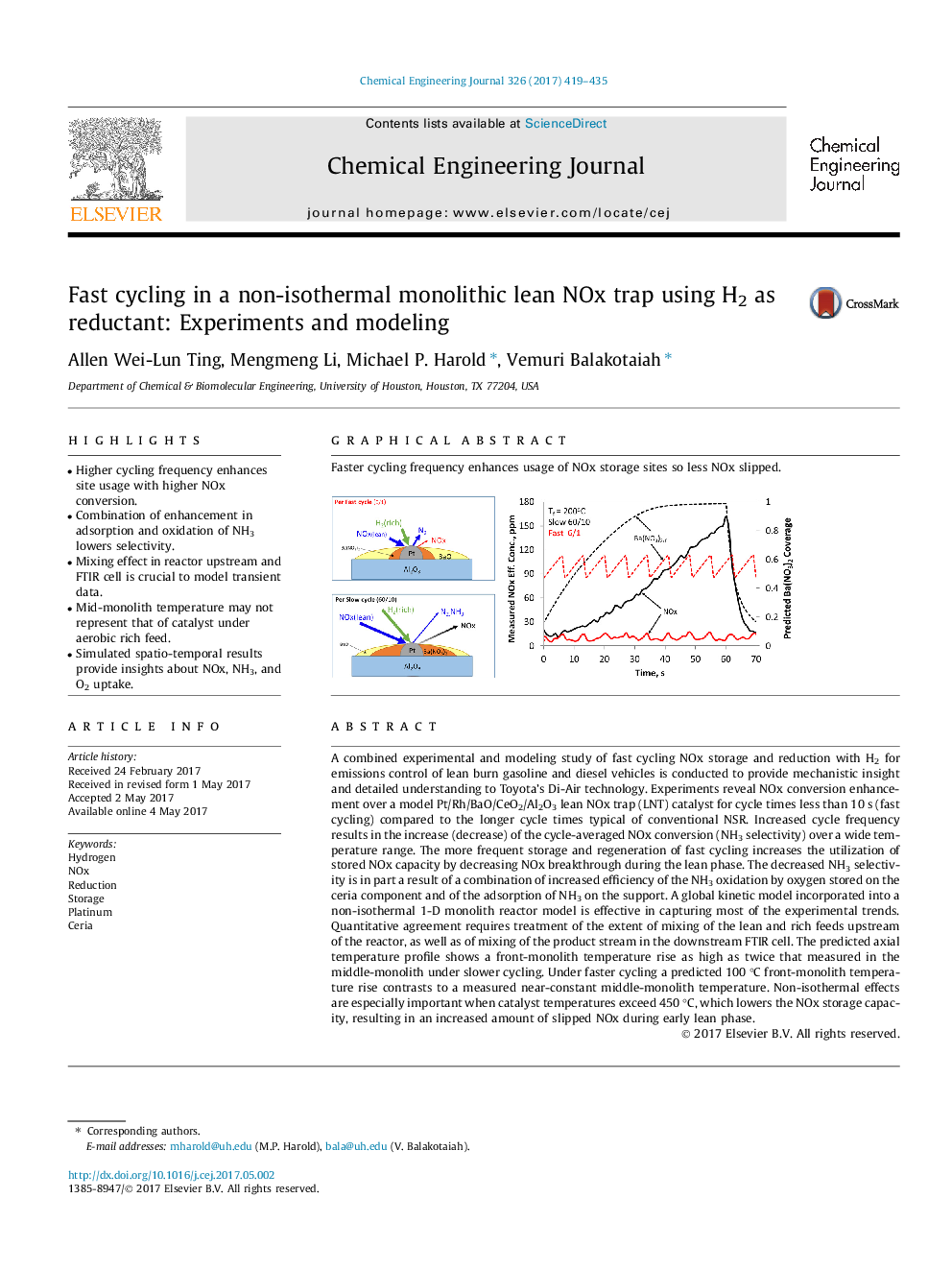

• Higher cycling frequency enhances site usage with higher NOx conversion.

• Combination of enhancement in adsorption and oxidation of NH3 lowers selectivity.

• Mixing effect in reactor upstream and FTIR cell is crucial to model transient data.

• Mid-monolith temperature may not represent that of catalyst under aerobic rich feed.

• Simulated spatio-temporal results provide insights about NOx, NH3, and O2 uptake.

A combined experimental and modeling study of fast cycling NOx storage and reduction with H2 for emissions control of lean burn gasoline and diesel vehicles is conducted to provide mechanistic insight and detailed understanding to Toyota’s Di-Air technology. Experiments reveal NOx conversion enhancement over a model Pt/Rh/BaO/CeO2/Al2O3 lean NOx trap (LNT) catalyst for cycle times less than 10 s (fast cycling) compared to the longer cycle times typical of conventional NSR. Increased cycle frequency results in the increase (decrease) of the cycle-averaged NOx conversion (NH3 selectivity) over a wide temperature range. The more frequent storage and regeneration of fast cycling increases the utilization of stored NOx capacity by decreasing NOx breakthrough during the lean phase. The decreased NH3 selectivity is in part a result of a combination of increased efficiency of the NH3 oxidation by oxygen stored on the ceria component and of the adsorption of NH3 on the support. A global kinetic model incorporated into a non-isothermal 1-D monolith reactor model is effective in capturing most of the experimental trends. Quantitative agreement requires treatment of the extent of mixing of the lean and rich feeds upstream of the reactor, as well as of mixing of the product stream in the downstream FTIR cell. The predicted axial temperature profile shows a front-monolith temperature rise as high as twice that measured in the middle-monolith under slower cycling. Under faster cycling a predicted 100 °C front-monolith temperature rise contrasts to a measured near-constant middle-monolith temperature. Non-isothermal effects are especially important when catalyst temperatures exceed 450 °C, which lowers the NOx storage capacity, resulting in an increased amount of slipped NOx during early lean phase.

Faster cycling frequency enhances usage of NOx storage sites so less NOx slipped.Figure optionsDownload high-quality image (221 K)Download as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 326, 15 October 2017, Pages 419–435