| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6466737 | 1422968 | 2017 | 11 صفحه PDF | دانلود رایگان |

- Intensification of gas-phase heterogeneous photocatalysis using a static mixer.

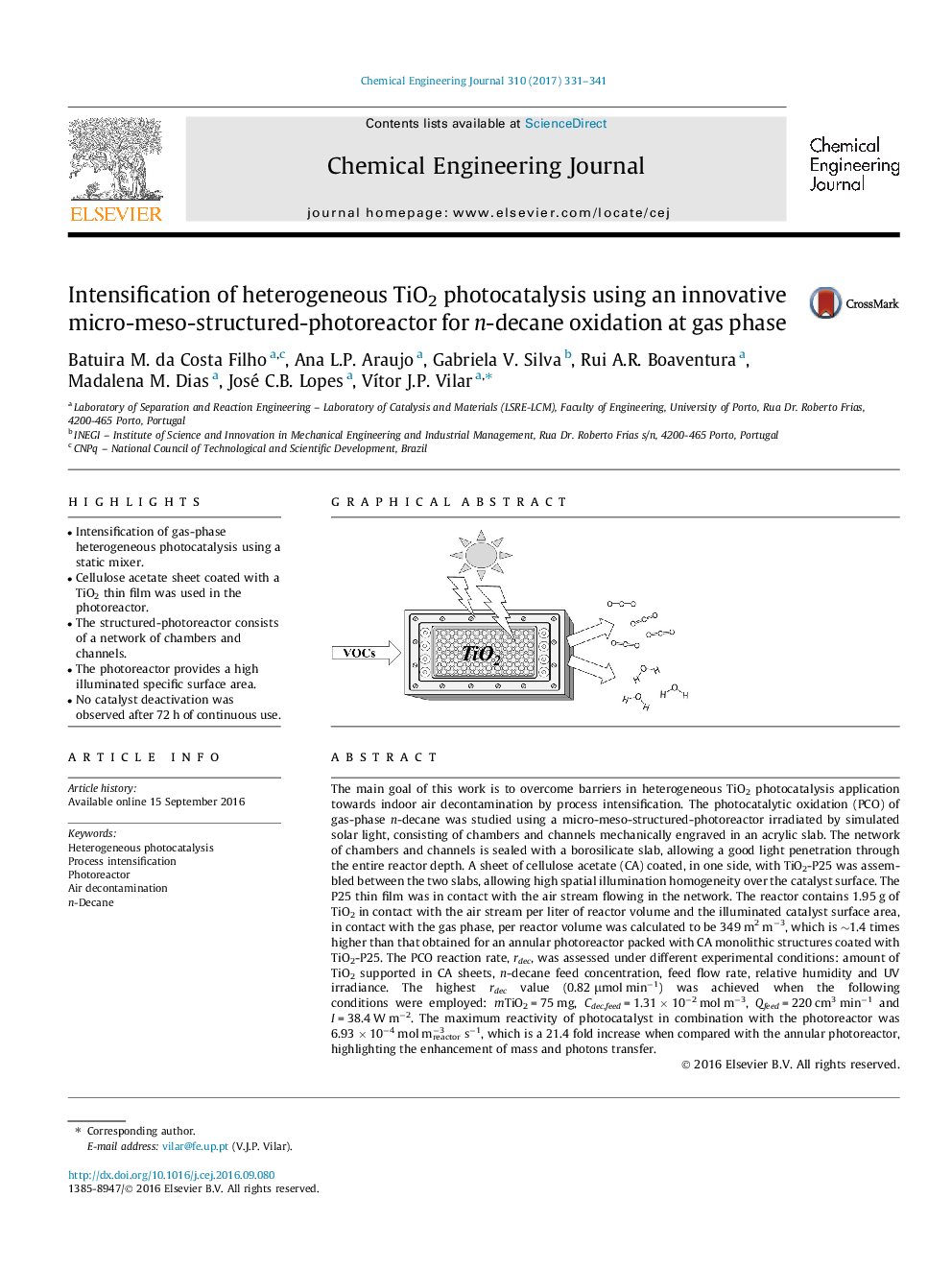

- Cellulose acetate sheet coated with a TiO2 thin film was used in the photoreactor.

- The structured-photoreactor consists of a network of chambers and channels.

- The photoreactor provides a high illuminated specific surface area.

- No catalyst deactivation was observed after 72Â h of continuous use.

The main goal of this work is to overcome barriers in heterogeneous TiO2 photocatalysis application towards indoor air decontamination by process intensification. The photocatalytic oxidation (PCO) of gas-phase n-decane was studied using a micro-meso-structured-photoreactor irradiated by simulated solar light, consisting of chambers and channels mechanically engraved in an acrylic slab. The network of chambers and channels is sealed with a borosilicate slab, allowing a good light penetration through the entire reactor depth. A sheet of cellulose acetate (CA) coated, in one side, with TiO2-P25 was assembled between the two slabs, allowing high spatial illumination homogeneity over the catalyst surface. The P25 thin film was in contact with the air stream flowing in the network. The reactor contains 1.95 g of TiO2 in contact with the air stream per liter of reactor volume and the illuminated catalyst surface area, in contact with the gas phase, per reactor volume was calculated to be 349 m2 mâ3, which is â¼1.4 times higher than that obtained for an annular photoreactor packed with CA monolithic structures coated with TiO2-P25. The PCO reaction rate, rdec, was assessed under different experimental conditions: amount of TiO2 supported in CA sheets, n-decane feed concentration, feed flow rate, relative humidity and UV irradiance. The highest rdec value (0.82 μmol minâ1) was achieved when the following conditions were employed: mTiO2 = 75 mg, Cdec,feed = 1.31 Ã 10â2 mol mâ3, Qfeed = 220 cm3 minâ1 and I = 38.4 W mâ2. The maximum reactivity of photocatalyst in combination with the photoreactor was 6.93 Ã 10â4 mol mâ3reactor sâ1, which is a 21.4 fold increase when compared with the annular photoreactor, highlighting the enhancement of mass and photons transfer.

Journal: Chemical Engineering Journal - Volume 310, Part 2, 15 February 2017, Pages 331-341