| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6474790 | 1424965 | 2017 | 10 صفحه PDF | دانلود رایگان |

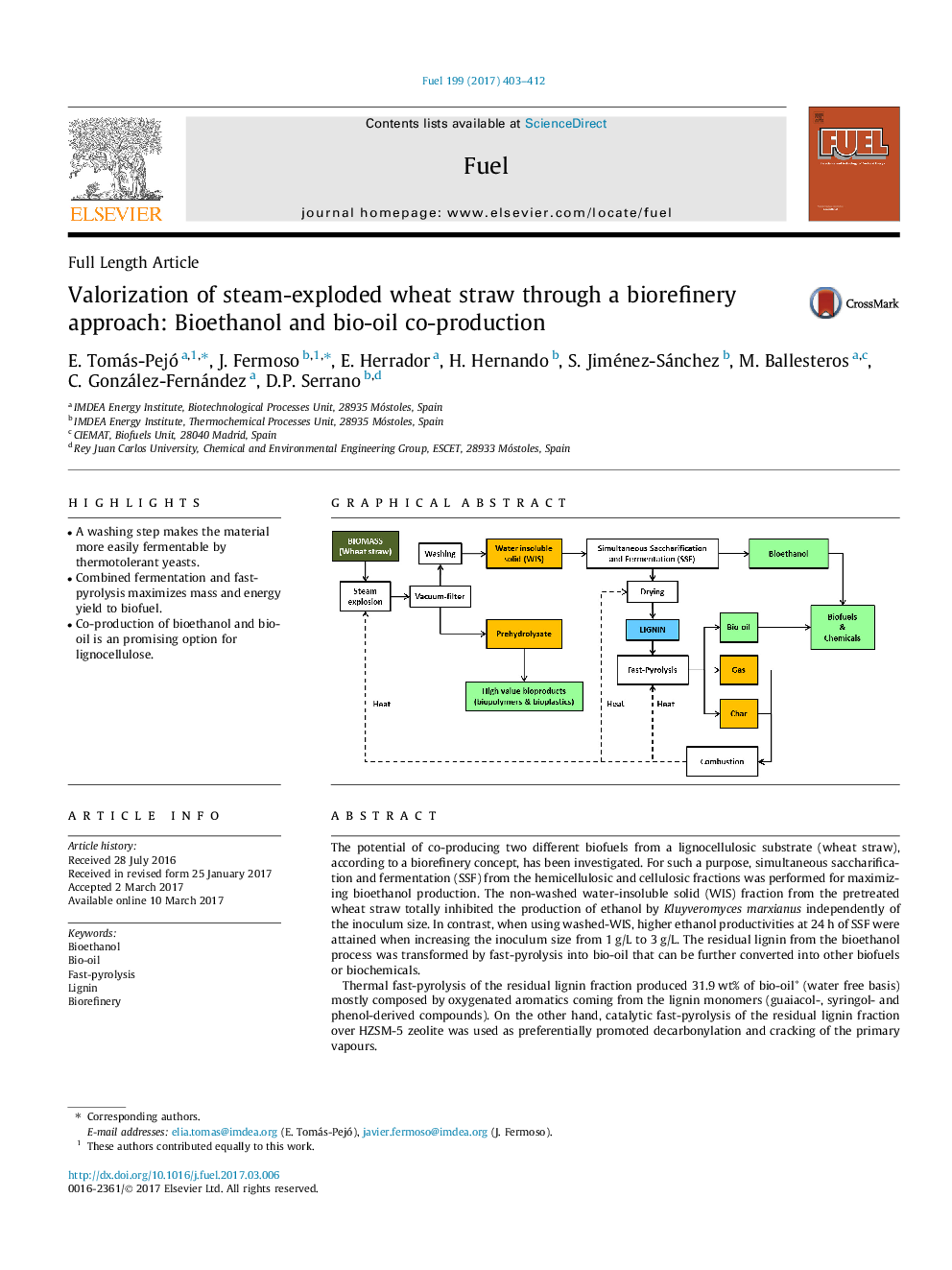

- A washing step makes the material more easily fermentable by thermotolerant yeasts.

- Combined fermentation and fast-pyrolysis maximizes mass and energy yield to biofuel.

- Co-production of bioethanol and bio-oil is an promising option for lignocellulose.

The potential of co-producing two different biofuels from a lignocellulosic substrate (wheat straw), according to a biorefinery concept, has been investigated. For such a purpose, simultaneous saccharification and fermentation (SSF) from the hemicellulosic and cellulosic fractions was performed for maximizing bioethanol production. The non-washed water-insoluble solid (WIS) fraction from the pretreated wheat straw totally inhibited the production of ethanol by Kluyveromyces marxianus independently of the inoculum size. In contrast, when using washed-WIS, higher ethanol productivities at 24Â h of SSF were attained when increasing the inoculum size from 1Â g/L to 3Â g/L. The residual lignin from the bioethanol process was transformed by fast-pyrolysis into bio-oil that can be further converted into other biofuels or biochemicals.Thermal fast-pyrolysis of the residual lignin fraction produced 31.9Â wt% of bio-oilâ (water free basis) mostly composed by oxygenated aromatics coming from the lignin monomers (guaiacol-, syringol- and phenol-derived compounds). On the other hand, catalytic fast-pyrolysis of the residual lignin fraction over HZSM-5 zeolite was used as preferentially promoted decarbonylation and cracking of the primary vapours.Coupling both processes significantly enhanced the production of liquid products from lignocellulose, improving the efficiency in the use of the raw material. In this way, compared to a simple process of bioethanol production, this approach allowed to increase the mass and the chemical energy yields 1.9 and 1.7-fold, respectively.

80

Journal: Fuel - Volume 199, 1 July 2017, Pages 403-412