| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6476030 | 1424978 | 2016 | 11 صفحه PDF | دانلود رایگان |

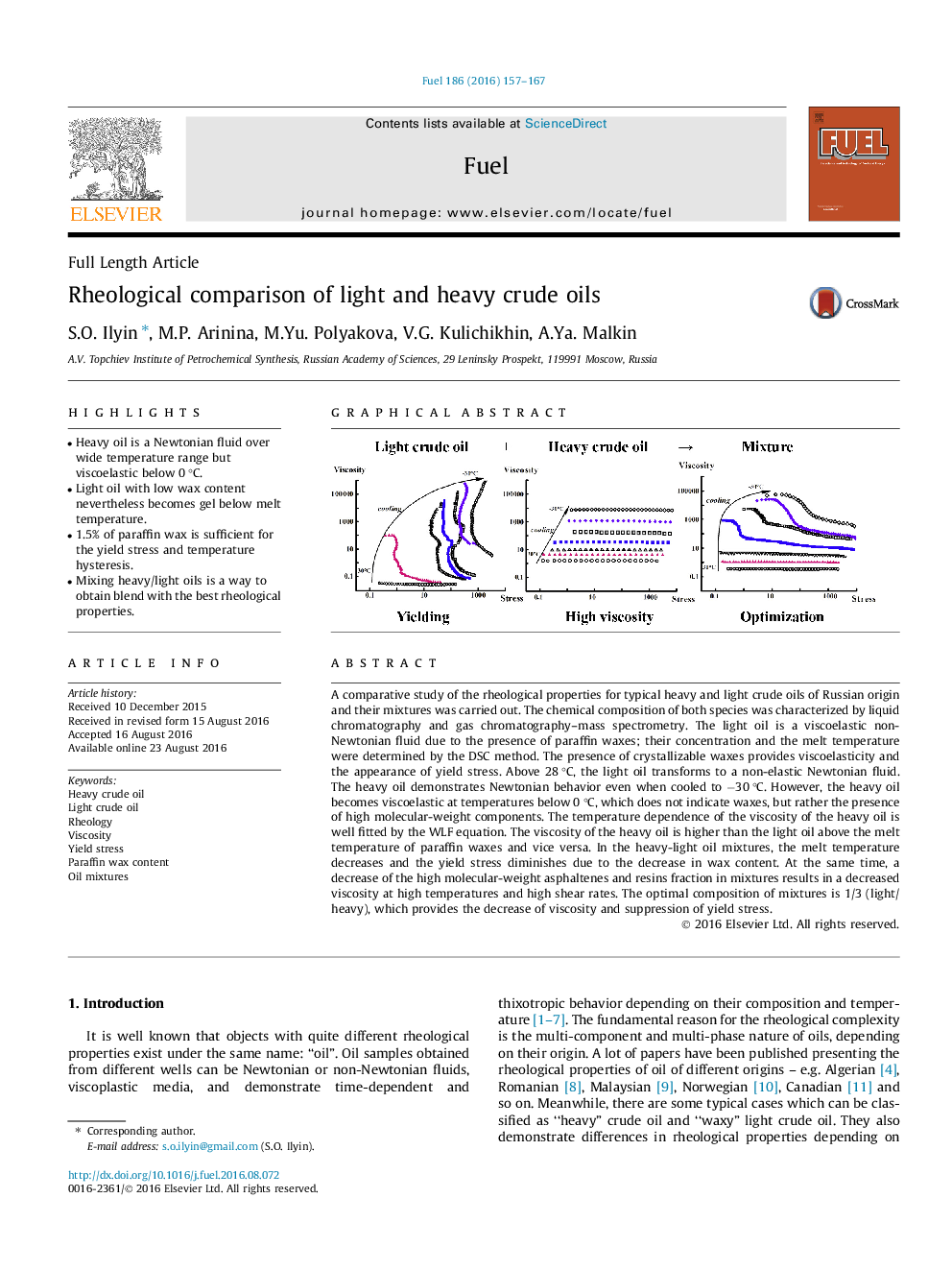

- Heavy oil is a Newtonian fluid over wide temperature range but viscoelastic below 0 °C.

- Light oil with low wax content nevertheless becomes gel below melt temperature.

- 1.5% of paraffin wax is sufficient for the yield stress and temperature hysteresis.

- Mixing heavy/light oils is a way to obtain blend with the best rheological properties.

A comparative study of the rheological properties for typical heavy and light crude oils of Russian origin and their mixtures was carried out. The chemical composition of both species was characterized by liquid chromatography and gas chromatography-mass spectrometry. The light oil is a viscoelastic non-Newtonian fluid due to the presence of paraffin waxes; their concentration and the melt temperature were determined by the DSC method. The presence of crystallizable waxes provides viscoelasticity and the appearance of yield stress. Above 28 °C, the light oil transforms to a non-elastic Newtonian fluid. The heavy oil demonstrates Newtonian behavior even when cooled to â30 °C. However, the heavy oil becomes viscoelastic at temperatures below 0 °C, which does not indicate waxes, but rather the presence of high molecular-weight components. The temperature dependence of the viscosity of the heavy oil is well fitted by the WLF equation. The viscosity of the heavy oil is higher than the light oil above the melt temperature of paraffin waxes and vice versa. In the heavy-light oil mixtures, the melt temperature decreases and the yield stress diminishes due to the decrease in wax content. At the same time, a decrease of the high molecular-weight asphaltenes and resins fraction in mixtures results in a decreased viscosity at high temperatures and high shear rates. The optimal composition of mixtures is 1/3 (light/heavy), which provides the decrease of viscosity and suppression of yield stress.

Graphical Abstract206

Journal: Fuel - Volume 186, 15 December 2016, Pages 157-167