| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 680475 | 1459973 | 2014 | 6 صفحه PDF | دانلود رایگان |

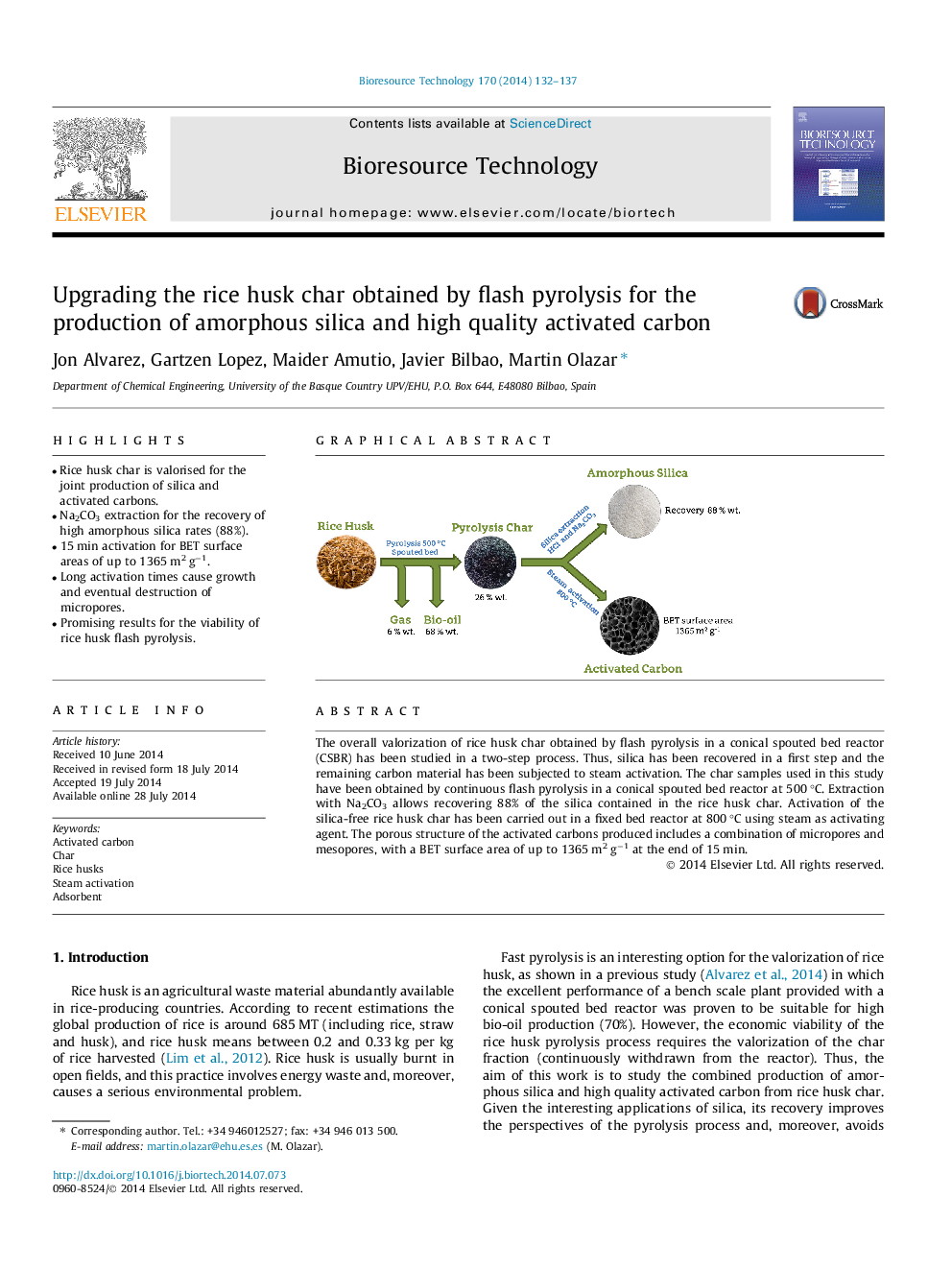

• Rice husk char is valorised for the joint production of silica and activated carbons.

• Na2CO3 extraction for the recovery of high amorphous silica rates (88%).

• 15 min activation for BET surface areas of up to 1365 m2 g−1.

• Long activation times cause growth and eventual destruction of micropores.

• Promising results for the viability of rice husk flash pyrolysis.

The overall valorization of rice husk char obtained by flash pyrolysis in a conical spouted bed reactor (CSBR) has been studied in a two-step process. Thus, silica has been recovered in a first step and the remaining carbon material has been subjected to steam activation. The char samples used in this study have been obtained by continuous flash pyrolysis in a conical spouted bed reactor at 500 °C. Extraction with Na2CO3 allows recovering 88% of the silica contained in the rice husk char. Activation of the silica-free rice husk char has been carried out in a fixed bed reactor at 800 °C using steam as activating agent. The porous structure of the activated carbons produced includes a combination of micropores and mesopores, with a BET surface area of up to 1365 m2 g−1 at the end of 15 min.

Figure optionsDownload as PowerPoint slide

Journal: Bioresource Technology - Volume 170, October 2014, Pages 132–137