| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 1286851 | 1497973 | 2014 | 11 صفحه PDF | دانلود رایگان |

• Cobalt was completely recovered from self-driven MFC–MEC system.

• A cobalt leaching rate of 46 ± 2 mg L−1 h−1 was obtained in MFCs.

• A Co(II) reduction rate of 7.0 ± 0.0 mg L−1 h−1 was achieved in MECs.

• There was an overall system cobalt yield of 0.15 ± 0.01 g Co g−1 Co in this system.

• Cobalt yields and operational efficiencies were assessed under various conditions.

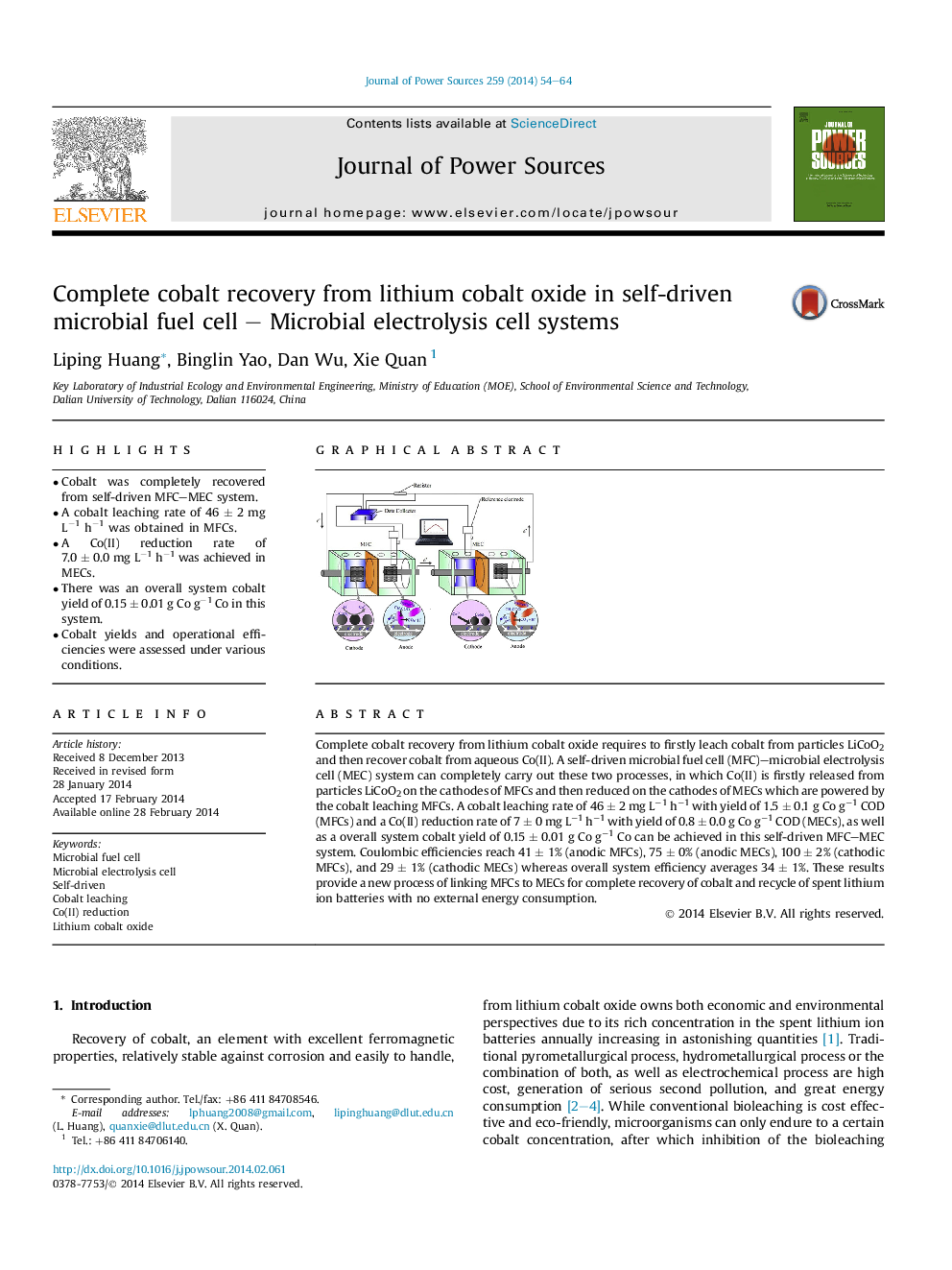

Complete cobalt recovery from lithium cobalt oxide requires to firstly leach cobalt from particles LiCoO2 and then recover cobalt from aqueous Co(II). A self-driven microbial fuel cell (MFC)–microbial electrolysis cell (MEC) system can completely carry out these two processes, in which Co(II) is firstly released from particles LiCoO2 on the cathodes of MFCs and then reduced on the cathodes of MECs which are powered by the cobalt leaching MFCs. A cobalt leaching rate of 46 ± 2 mg L−1 h−1 with yield of 1.5 ± 0.1 g Co g−1 COD (MFCs) and a Co(II) reduction rate of 7 ± 0 mg L−1 h−1 with yield of 0.8 ± 0.0 g Co g−1 COD (MECs), as well as a overall system cobalt yield of 0.15 ± 0.01 g Co g−1 Co can be achieved in this self-driven MFC–MEC system. Coulombic efficiencies reach 41 ± 1% (anodic MFCs), 75 ± 0% (anodic MECs), 100 ± 2% (cathodic MFCs), and 29 ± 1% (cathodic MECs) whereas overall system efficiency averages 34 ± 1%. These results provide a new process of linking MFCs to MECs for complete recovery of cobalt and recycle of spent lithium ion batteries with no external energy consumption.

Figure optionsDownload as PowerPoint slide

Journal: Journal of Power Sources - Volume 259, 1 August 2014, Pages 54–64